Nov . 08, 2024 06:57 Back to list

Exploring the Benefits and Applications of Y-Type Strainers in Industrial Use

Understanding Y-Type Strainers A Key Component in Fluid Filtration

Y-type strainers are an essential piece of equipment used in various industrial applications to protect pipelines and equipment from unwanted debris and contaminants. Particularly prominent in fluid systems, they play a crucial role in ensuring the smooth operation of pumps, valves, and other machinery. The importance of Y-type strainers cannot be overstated, as they significantly extend the lifespan of valuable equipment and enhance system performance.

What is a Y-Type Strainer?

A Y-type strainer is a passive filtration device designed to remove solid particles from liquids and gases. Its distinctive 'Y' shape provides a compact design that allows for easy integration into existing piping systems. Typically made from durable materials such as stainless steel, carbon steel, or plastic, Y-type strainers are highly effective and versatile.

The strainer functions by directing the flow of fluid through a mesh or perforated screen. As the fluid passes through, solid impurities are captured on the screen's surface, which can then be cleaned or replaced as necessary. The captured debris varies in size and type, ranging from scale and rust to larger particulates that could cause damage to downstream components.

Key Features and Benefits

1. Compact Design The Y-shape allows these strainers to be installed in tight spaces without compromising performance. Their design also facilitates easy maintenance and cleaning.

2. Versatility Y-type strainers can be used for various applications, including water, oil, gas, and other liquids. This makes them suitable for industries like petrochemical, food and beverage, and water treatment.

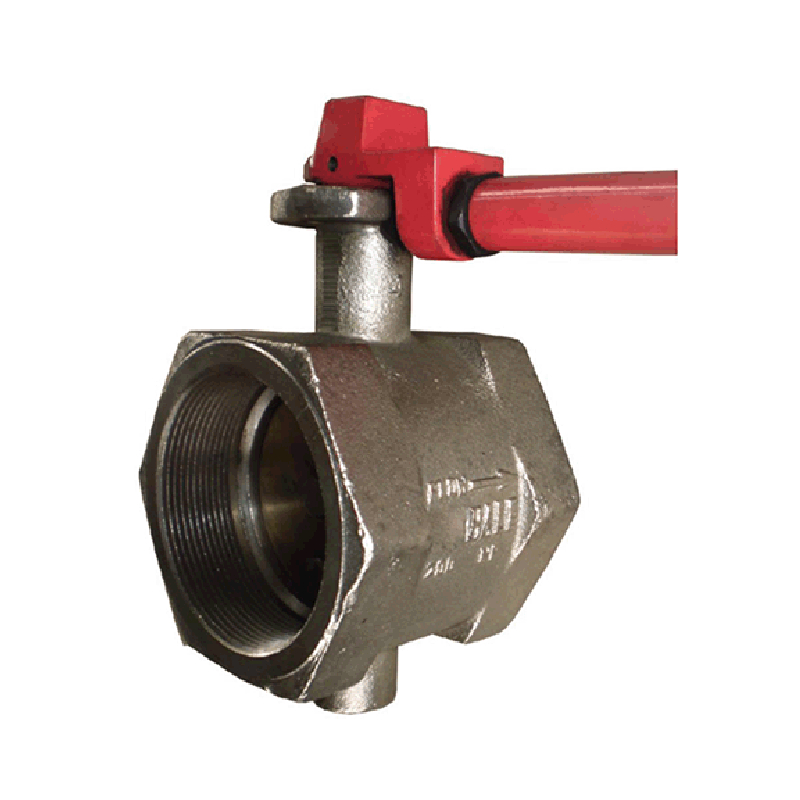

y type strainer

3. Enhanced Equipment Longevity By filtering out contaminants, Y-type strainers prevent damage to pumps, valves, and other equipment. This protection reduces maintenance costs and downtime, leading to improved operational efficiency.

4. Easy Maintenance Regular maintenance of a Y-type strainer involves removing the strainer from the pipeline and cleaning the filter element. Many designs incorporate a blow-off valve that allows for in-line cleaning without removing the strainer, making maintenance simpler and more efficient.

5. Cost-Effective Compared to the potential costs of equipment replacement and downtime caused by clogged systems, Y-type strainers provide a cost-effective solution for preventing system failures.

Applications of Y-Type Strainers

Industries that heavily rely on Y-type strainers include

- Water Treatment In water treatment facilities, Y-type strainers filter out sediments and debris to ensure clean water delivery. - Oil and Gas The oil and gas industry uses Y-type strainers to protect sensitive equipment from particulate contamination, which can lead to costly disruptions. - Food Processing In food production, maintaining hygiene is critical, making Y-type strainers vital for eliminating foreign particles from processing lines.

Conclusion

In summary, Y-type strainers are pivotal in maintaining the integrity and efficiency of fluid systems across various industries. Their compact design, versatility, and ability to protect critical equipment make them a smart investment for any operation that relies on fluid transport. By incorporating Y-type strainers into your system, you can ensure cleaner fluids, extended equipment life, and a more efficient operational workflow. As industrial applications grow more complex, the role of effective filtration solutions like Y-type strainers will continue to be essential in safeguarding machinery and enhancing productivity.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025