Dec . 05, 2024 12:44 Back to list

Understanding Y Strainers and Their ANSI Standards for Optimal Performance

Understanding Y-Strainers A Key Component in ANSI Systems

Y-strainers are vital components in various piping systems, especially within ANSI (American National Standards Institute) frameworks. As their name suggests, Y-strainers are shaped like the letter Y, which provides them with a distinctive appearance and functionality that sets them apart from other types of strainers. Their primary purpose is to filter out debris and solids from liquids or gases passing through a pipeline, making them essential for maintaining the integrity and efficiency of industrial systems.

Design and Functionality

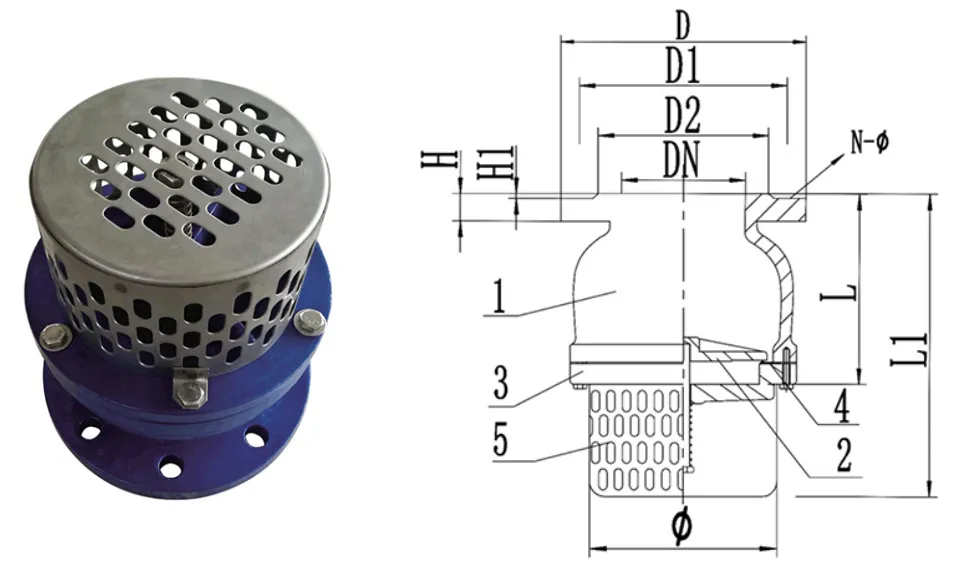

Y-strainers are typically constructed from durable materials such as stainless steel, carbon steel, or bronze, making them suitable for a wide range of applications, including water treatment, oil and gas, and chemical processing. The Y-shaped design features a body with two ends connected to the pipeline and a screen or mesh filter located in the lower section, which captures particles as fluids flow through. The fluid enters the strainer through the top, travels down into the filter, and exits through the side outlet, ensuring that larger impurities are retained.

One of the key advantages of Y-strainers is their ease of maintenance. The removable screen can be cleaned or replaced without removing the entire strainer from the pipeline, simplifying service and reducing downtime. Depending on the design, some Y-strainers are equipped with a drain valve, allowing for easy removal of captured debris without complete disassembly, which is particularly beneficial in systems where continuous operation is crucial.

ANSI Standards and Specifications

In the realm of industrial applications, adherence to ANSI standards is critical for ensuring safety, reliability, and performance. Y-strainers manufactured to ANSI specifications are designed to meet specific pressure and temperature ratings, making them compatible with a variety of system requirements. These standards dictate materials, dimensions, testing, and quality control measures to guarantee that the strainer performs optimally within its designated parameters.

ANSI class ratings (such as 150, 300, and 600) denote the maximum allowable pressure for the fittings and flanges that Y-strainers use. The choice of a specific rating depends on the application requirements and the operating conditions of the system. Selecting the appropriate Y-strainer based on its ANSI rating ensures that the component can withstand the pressure and temperature of the fluids it will interact with, thus promoting overall system reliability.

y strainer ansi

Applications and Benefits

Y-strainers are widely utilized in various industries, including

1. Water Treatment In municipal and industrial water treatment facilities, Y-strainers prevent contaminants from entering pumps and other equipment, thereby prolonging their lifespan and enhancing operational efficiency.

2. Power Generation In power plants, Y-strainers protect turbines and other critical components from particulate matter, ensuring smooth operation and reducing maintenance costs.

3. Chemical Processing Chemical plants use Y-strainers to maintain product purity by filtering out unwanted solids from the process fluids, which is essential for meeting quality standards.

4. Oil and Gas In oil and gas applications, Y-strainers safeguard pipelines and valves from debris, which can otherwise lead to costly repairs and operational interruptions.

Conclusion

Y-strainers are indispensable components in ANSI-compliant systems, offering a straightforward yet effective solution to the challenge of filtering debris and solids. Their robust design, easy maintenance, and adherence to stringent industry standards make them suitable for a wide range of applications, from water treatment facilities to oil and gas pipelines. By investing in quality Y-strainers, industries can enhance the reliability of their systems, reduce downtime, and ultimately improve overall operational efficiency. Understanding the functionality and importance of Y-strainers within ANSI frameworks is essential for engineers and operators aiming to maintain optimal system performance.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025