Jan . 31, 2025 01:30 Back to list

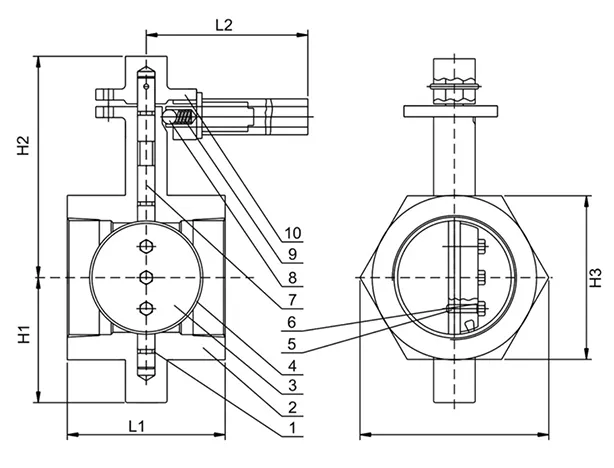

y strainer 4 inch

When it comes to ensuring the longevity and efficiency of fluid systems, the 4-inch Y strainer stands as a vital component in industrial applications. Designed to filter out solids from flowing liquids or gases, this particular size of Y strainer is indispensable for a myriad of sectors ranging from water treatment facilities to chemical processing plants.

Authoritative knowledge in fluid system management suggests that the integration of a 4-inch Y strainer can prevent costly downtime by protecting expensive machinery downstream. By capturing debris and particulates before they can cause blockages or damage, these strainers act as the first line of defense. Industries have reported significant reductions in maintenance cost and downtime following the implementation of strategically placed strainers in their systems. Trustworthiness in the configuration of these devices extends to the predictability and reliability they bring to processes. As the installation of a Y strainer is often dictated by the type and velocity of the fluid, expert consultation is recommended. Understanding the specific needs of your system can ensure optimal placement and sizing, thereby maximizing the strainer's operational benefits. For industries where precision and reliability are paramount, engaging with suppliers known for their expertise and quality assurance is vital. Reputable manufacturers will offer certificates of compliance and quality assurance tests for their products, adding an extra layer of trustworthiness to your investment. In conclusion, the 4-inch Y strainer is not just an accessory but a pivotal element of fluid management systems. Its design is rooted in engineering excellence, offering a balance of simplicity and functionality. For businesses looking to enhance their system's reliability and efficiency, investing in a high-quality Y strainer, tailored to their specific operational requirements, is a strategic move that promises long-term benefits.

Authoritative knowledge in fluid system management suggests that the integration of a 4-inch Y strainer can prevent costly downtime by protecting expensive machinery downstream. By capturing debris and particulates before they can cause blockages or damage, these strainers act as the first line of defense. Industries have reported significant reductions in maintenance cost and downtime following the implementation of strategically placed strainers in their systems. Trustworthiness in the configuration of these devices extends to the predictability and reliability they bring to processes. As the installation of a Y strainer is often dictated by the type and velocity of the fluid, expert consultation is recommended. Understanding the specific needs of your system can ensure optimal placement and sizing, thereby maximizing the strainer's operational benefits. For industries where precision and reliability are paramount, engaging with suppliers known for their expertise and quality assurance is vital. Reputable manufacturers will offer certificates of compliance and quality assurance tests for their products, adding an extra layer of trustworthiness to your investment. In conclusion, the 4-inch Y strainer is not just an accessory but a pivotal element of fluid management systems. Its design is rooted in engineering excellence, offering a balance of simplicity and functionality. For businesses looking to enhance their system's reliability and efficiency, investing in a high-quality Y strainer, tailored to their specific operational requirements, is a strategic move that promises long-term benefits.

Share

Prev:

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025