Oct . 22, 2024 10:00 Back to list

wafer type silent check valve

Understanding Wafer Type Silent Check Valves

In the realm of fluid control, valves play a crucial role in ensuring efficient operation within various systems. Among them, the wafer type silent check valve stands out for its unique design and advantages. This article delves into the features, benefits, applications, and considerations of wafer type silent check valves, providing a comprehensive overview for engineers and industry professionals.

What is a Wafer Type Silent Check Valve?

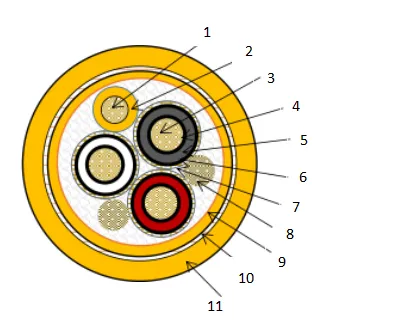

A wafer type silent check valve is a specific kind of check valve designed to allow fluid to flow in one direction while preventing backflow. Its unique “wafer” design consists of a compact and lightweight body that can be sandwiched between two flanges within a piping system. Unlike traditional check valves, which can be bulky and require more space, wafer type valves offer a streamlined solution that fits seamlessly into pipelines.

Key Features

- Compact Design The wafer design reduces the overall footprint of the valve, making it an excellent choice for confined spaces in various industrial settings. - Low Maintenance Silent check valves are engineered to minimize noise generated by the closure mechanism, thus reducing maintenance efforts associated with noise pollution and vibration issues often found in traditional check valves.

- Durability Typically constructed from robust materials such as stainless steel, cast iron, or ductile iron, these valves are built to withstand harsh conditions, including high pressure and temperature variations.

- Spring-assisted Mechanism Many wafer silent check valves incorporate a spring mechanism that allows for smoother operation and quicker closure, minimizing the risk of water hammer or backflow.

Benefits

The advantages of wafer type silent check valves are manifold. First and foremost is their ability to prevent backflow, which is critical in applications where reverse flow can cause contamination or damage to equipment. Their compact design not only saves space but also simplifies the installation process, leading to reduced labor costs.

wafer type silent check valve

Moreover, their efficiency in operation allows for increased system reliability. In industries such as water treatment, chemical processing, and HVAC, maintaining consistent flow and protecting the integrity of the system is paramount. The silent operation of these valves also contributes to a more pleasant working environment, particularly in settings where noise reduction is desired.

Applications

Wafer type silent check valves are versatile and widely used across various industries. Common applications include

- Water Supply and Distribution To ensure that water flows in the intended direction and prevent contamination. - Pumping Systems To protect pumps from potential backflow, thereby extending their lifespan.

- HVAC Systems To maintain efficient operation and prevent reverse flow in heating and cooling applications.

- Chemical Processing To safeguard against backflow in pipelines carrying hazardous materials, ensuring safety and compliance with regulations.

Considerations

When selecting a wafer type silent check valve, it is essential to consider factors such as the fluid type, temperature, pressure, and compatibility with existing piping materials. Proper sizing and selection will ensure optimal performance and longevity.

In conclusion, wafer type silent check valves offer an effective solution for various fluid control needs. Their compact design, low maintenance requirements, and reliability make them an excellent choice for industries seeking efficient and quiet operation. As technology continues to evolve, these valves will likely see further advancements, enhancing their role in fluid management systems around the world.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025