Dec . 05, 2024 11:28 Back to list

Flanged Butterfly Valves for Different Wafer Types in Pipeline Applications

Understanding Wafer Type Butterfly Valve Flanges

In industrial applications, particularly those involving fluid handling, the choice of valves is critical to ensure efficient and safe operations. One popular option is the wafer type butterfly valve, known for its compact design and versatility. This article delves into the significance of flanges in wafer type butterfly valves, their construction, applications, and key considerations for selection.

What is a Wafer Type Butterfly Valve?

A wafer type butterfly valve is a quarter-turn rotational valve that uses a disc to control the flow of fluid. The disc is positioned in the middle of the pipe and is rotated to either open or close the flow passage. This design offers several advantages, particularly in terms of space savings, lightweight construction, and ease of installation. Unlike lug and flanged butterfly valves, wafer type valves are designed to be sandwiched between two pipe flanges, allowing for a more compact installation.

The Role of Flanges

Flanges are critical components in piping systems, providing a means of connecting sections of pipe, and they play a key role in the installation of wafer type butterfly valves. In a wafer valve assembly, the valve body has mounting holes that align with the flanges on either side of the valve. These flanges create a tight seal to prevent leaks while allowing for the ease of disassembly for maintenance or replacement.

Wafer type butterfly valves typically use two types of flanges ANSI flanges and DIN flanges. ANSI flanges conform to the American National Standards Institute specifications, while DIN flanges meet European standards. The choice between these two often depends on the specific requirements of the piping system and regional practices.

Construction of Wafer Type Butterfly Valve Flanges

Flanges on wafer type butterfly valves can be made from various materials, such as carbon steel, stainless steel, or plastic, depending on the application requirements. The materials chosen typically reflect the medium being transported, the temperature and pressure conditions, and the need for corrosion resistance.

For high-pressure and high-temperature applications, stainless steel flanges are often preferred due to their strength and resistance to corrosion. On the other hand, carbon steel flanges may be adequate for lower pressures and less corrosive environments. Additionally, the design of the flange must consider the connection type, which could include raised face, flat face, or ring-type joint.

wafer type butterfly valve flange

Applications of Wafer Type Butterfly Valves

Wafer type butterfly valves are widely used in various industries, including water treatment, oil and gas, power generation, food processing, and chemical processing

. Their ability to handle a diverse range of fluids, including viscous and abrasive media, makes them suitable for both general and specialized applications.In water treatment plants, for instance, these valves help regulate flow rates and manage water distribution efficiently. In the oil and gas industry, the durability of wafer type butterfly valves under harsh conditions is invaluable, ensuring safe transit and handling of oil and gas products.

Key Considerations for Selection

When selecting wafer type butterfly valves and their corresponding flanges, several factors must be taken into account

1. Material Compatibility Ensuring that the valve material is suitable for the fluid being handled to prevent degradation over time.

2. Pressure and Temperature Ratings Knowing the operating conditions including maximum pressures and temperatures to select a valve that can withstand these conditions safely.

3. Size and Dimensions The size of the valve must align with the dimensions of the existing piping system to guarantee a proper fit.

4. Standards Compliance Choosing flanges that conform to appropriate national or international standards to ensure compatibility and reliability.

In conclusion, wafer type butterfly valve flanges are essential components in ensuring the effective operation of fluid control systems. By understanding their construction, applications, and selection criteria, engineers and facility managers can make informed choices that enhance performance and safety in their operations.

Share

-

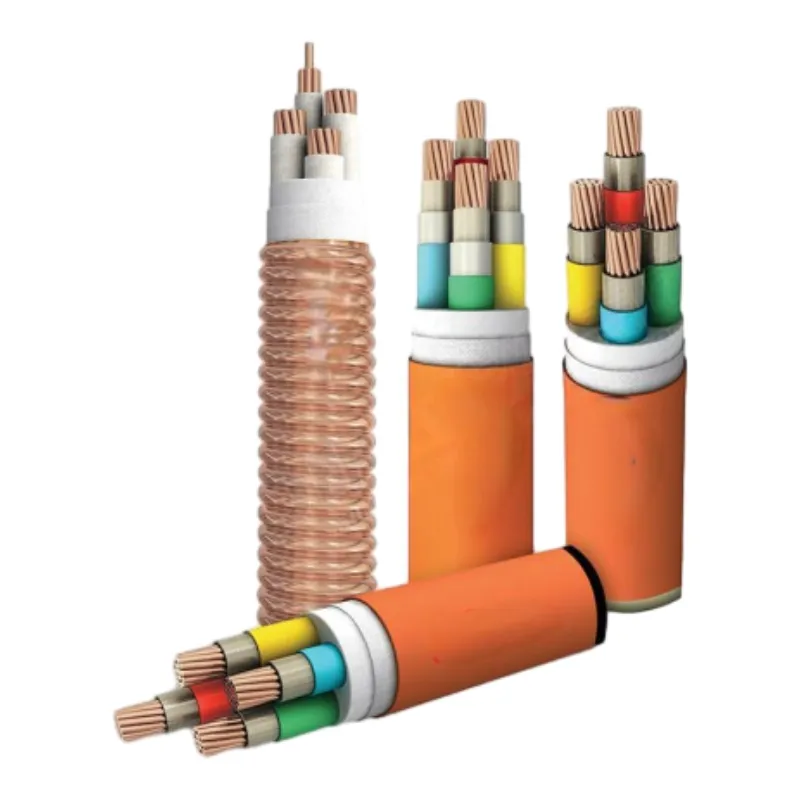

Advanced Technology in Wire and Cable FactoryNewsAug.19,2025

-

Applications of Ball Check Valve in Water Treatment PlantsNewsAug.19,2025

-

How Osy Gate Valve Ensures Leak - Tight SealingNewsAug.19,2025

-

Selection Criteria for Wafer Type Butterfly ValveNewsAug.19,2025

-

Threaded Ball Valve Pressure RatingsNewsAug.19,2025

-

Y Strainer PN16 Cost - Effectiveness AnalysisNewsAug.19,2025