Nov . 20, 2024 18:19 Back to list

wafer style check valve

Understanding Wafer Style Check Valves Design, Functionality, and Applications

Check valves are vital components in various fluid systems, ensuring that fluids flow in one direction while preventing reverse flow. Among the different types of check valves available, the wafer style check valve has gained prominence due to its unique design and functionality. In this article, we will explore the characteristics, advantages, and applications of wafer-style check valves, highlighting why they are a preferred choice in many industrial scenarios.

What is a Wafer Style Check Valve?

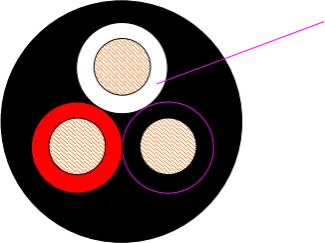

A wafer style check valve is a type of non-return valve that is installed between two flanges in a piping system. Unlike traditional check valves that may have a body and end connections, wafer check valves are designed to be thin and compact. Their design typically comprises two primary parts the body and the disc (or flap). The body contains openings for the fluid to flow through, while the disc is hinged or pivoted in a way that allows it to open when the fluid flows in the correct direction and close when there’s backflow.

Design Features

The wafer style check valve is characterized by its slim profile, making it an ideal choice for space-constrained applications. Typically, these valves are made from materials such as cast iron, stainless steel, or PVC, depending on the application requirements and the nature of the fluid being handled. The size of wafer check valves varies, but they can be manufactured to fit standard flange sizes, allowing for easy integration into existing piping systems.

One of the critical design features of wafer style check valves is their ability to prevent backflow efficiently. The disc is designed to respond quickly to changes in flow direction, shutting tightly to block any reverse flow. Additionally, some wafer check valves incorporate spring mechanisms that provide extra force to ensure the disc remains closed when there is no flow or during reverse pressure situations.

Advantages of Wafer Style Check Valves

1. Space Efficiency Due to their compact design, wafer check valves require less space compared to traditional check valves, making them ideal for systems where space is at a premium.

3. Low Pressure Drop The streamlined design of the wafer check valve minimizes turbulence and pressure drop in the system, ensuring efficient fluid flow.

wafer style check valve

4. Ease of Installation These valves are designed for easy installation between flanges, requiring fewer supports and less hardware.

5. Versatility Wafer style check valves can be used with various fluids, including water, oil, gas, and even corrosive substances, provided the materials are appropriately chosen.

6. Cost-Effectiveness Their simple design and ease of maintenance contribute to lower operational costs over time, making them a cost-effective solution for many applications.

Applications

Wafer style check valves find applications across various industries due to their reliability and effectiveness. Common applications include

- Water and Wastewater Treatment They help prevent backflow in treatment plants, ensuring efficient operation and protecting equipment from potential damage. - Chemical Processing These valves are suitable for handling various chemicals, providing safe and effective flow control in pipelines.

- Oil and Gas Wafer check valves are used in oil and gas applications to prevent backflow and protect pumps and compressors.

- HVAC Systems In heating, ventilation, and air conditioning systems, these valves play a crucial role in maintaining proper airflow and preventing system malfunctions.

- Power Generation Wafer check valves protect turbine systems and other equipment from reverse flow, enhancing operational safety and efficiency.

Conclusion

Wafer style check valves represent an efficient and reliable solution for controlling fluid flow in various applications. Their compact design, ease of installation, and versatility make them a popular choice across multiple industries. By understanding their design features and benefits, engineers and system designers can make informed decisions, ultimately enhancing the performance and safety of their fluid systems. As technology advances, wafer style check valves will continue to evolve, promising even greater reliability and efficiency in fluid management.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025