Nov . 07, 2024 08:58 Back to list

wafer style butterfly valve

Exploring Wafer Style Butterfly Valves A Comprehensive Overview

Wafer style butterfly valves are increasingly favored in various industrial applications due to their compact design, lightweight structure, and efficiency in regulating flow. These valves, resembling a butterfly in flight, utilize a rotating disc to control the passage of fluids through a pipeline. This article delves into the features, applications, and advantages of wafer style butterfly valves, shedding light on why they are a preferred choice in numerous sectors.

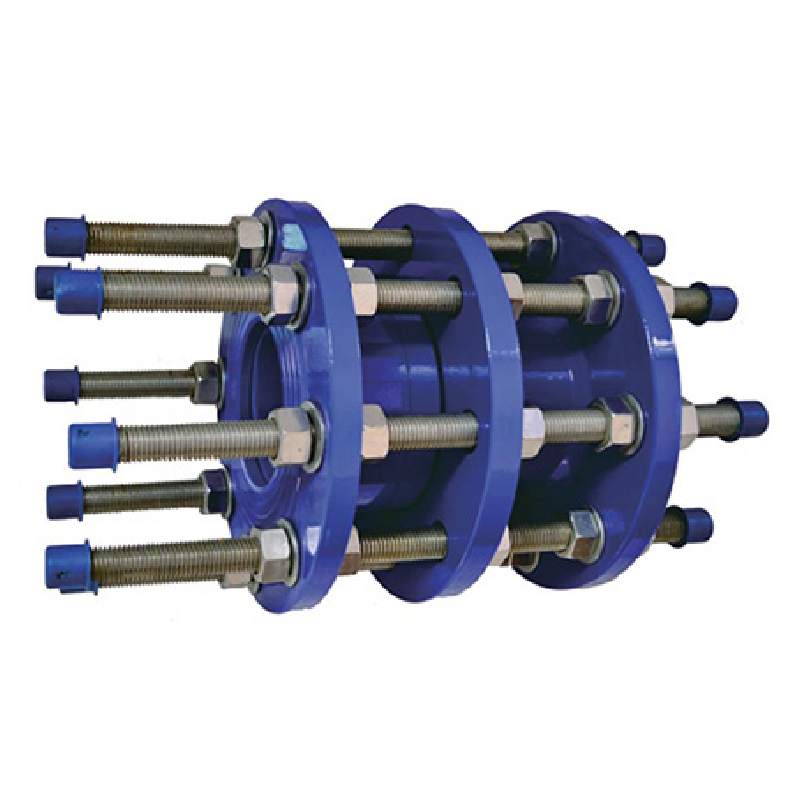

One of the key characteristics of wafer style butterfly valves is their unique mounting style. Unlike traditional valves that require flanged connections, wafer butterfly valves are sandwiched between two flanges. This design allows for easier installation and removal, reducing the amount of space needed compared to flanged valves. As a result, they are often utilized in systems where space is at a premium, such as in chemical processing, water treatment, and HVAC systems.

In terms of functionality, wafer style butterfly valves provide excellent flow control and are capable of managing both on-off and throttling applications. The disc, positioned at the center of the valve, pivots around a shaft, allowing for quick and smooth operation. This design minimizes pressure drop, making them highly efficient for fluid flow. Additionally, they can accommodate a wide range of fluids—such as water, oil, and gas—making them versatile for numerous industries.

wafer style butterfly valve

Another advantage of wafer style butterfly valves is their cost-effectiveness. Generally, they are less expensive compared to many other valve types, both in terms of initial purchase and maintenance costs. Their simple structure means that there are fewer parts that could potentially wear out, contributing to lower long-term operational expenses.

Moreover, wafer butterfly valves can be made from various materials, including stainless steel, cast iron, and plastic, enabling customization according to specific application requirements. This flexibility in material selection enhances their durability and corrosion resistance, ensuring longevity in challenging environments.

In summary, wafer style butterfly valves offer an efficient, cost-effective, and versatile solution for flow regulation in a variety of industrial applications. Their compact design, ease of installation, and ability to handle multiple fluid types make them a go-to choice for engineers and designers seeking reliable valve solutions. As industries continue to innovate and evolve, wafer style butterfly valves are set to play an essential role in optimizing systems and enhancing operational efficiency.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025