Nov . 22, 2024 19:03 Back to list

vulcanized seat flange butterfly valve

Understanding the Vulcanized Seat Flange Butterfly Valve

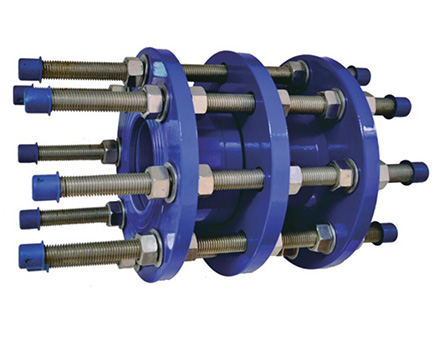

The vulcanized seat flange butterfly valve is a crucial component in various industrial applications, particularly in fluid control systems. This type of valve is designed to manage the flow of liquids and gases efficiently, providing reliable performance and longevity. Its unique construction features a vulcanized seating surface that enhances its sealing capability and durability.

One of the key attributes of the vulcanized seat flange butterfly valve is the vulcanization process used to create the seat material. Vulcanization involves the chemical modification of rubber, improving its hardness, elasticity, and temperature resistance. As a result, the seat offers superior sealing performance compared to traditional materials. This enhancement is especially beneficial in applications involving high pressures and temperatures, where conventional valves might fail due to thermal expansion or material degradation.

The flange design of the butterfly valve facilitates easy installation and maintenance. The flanges provide a secure connection to piping systems, ensuring minimal leakage during operation. This feature is particularly advantageous in environments where fluid loss can lead to significant safety and economic risks. Flanged connections also simplify the replacement process, allowing for quick maintenance without the need for specialized tools.

vulcanized seat flange butterfly valve

In addition to their robust construction, vulcanized seat flange butterfly valves are known for their lightweight design. This characteristic makes them easier to handle and install, reducing labor costs and installation time. Moreover, their compact design means they can be used in applications with space constraints, making them versatile for various industrial setups.

Another significant advantage of these valves is their ability to offer throttling capabilities. The design allows for precise regulation of flow, making vulcanized seat flange butterfly valves ideal for both on-off and flow control applications. Operators can easily adjust the position of the disc within the valve body to achieve the desired flow rate, which is vital for processes requiring specific fluid dynamics.

Vulcanized seat flange butterfly valves find applications across diverse industries, including water treatment, oil and gas, chemical processing, and HVAC systems. Their robustness and reliability make them a preferred choice for many engineers and designers. Furthermore, modern manufacturing techniques ensure that these valves meet stringent quality and performance standards, which is crucial for maintaining operational integrity in various applications.

In conclusion, the vulcanized seat flange butterfly valve is an essential component in fluid control systems, offering distinct advantages over traditional valve designs. With its enhanced sealing capabilities, lightweight structure, and ease of installation, it stands out as a reliable choice for numerous industrial applications. As industries continue to evolve and demand more efficient fluid management solutions, the importance of advanced valve technology, such as the vulcanized seat flange butterfly valve, cannot be overstated. Its role in promoting efficiency and safety in fluid systems positions it as a fundamental element in modern engineering and industrial practices.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025