Dec . 17, 2024 09:55 Back to list

threaded ball valve

The Versatility and Functionality of Threaded Ball Valves

In the realm of industrial applications, the importance of reliable and efficient flow control cannot be overstated. One pivotal component that serves this purpose is the threaded ball valve. This type of valve is renowned for its ability to regulate the flow of liquids and gases with precision and reliability, making it an indispensable tool in various sectors, from oil and gas to water treatment and manufacturing.

Design and Construction

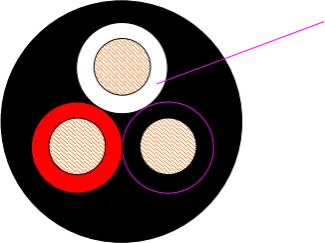

Threaded ball valves are typically constructed from robust materials such as stainless steel, brass, or plastic. Their design features a hollow, perforated, and pivoting ball – the core element that allows or restricts fluid flow. The ball is situated between two seats and can be turned 90 degrees to either allow or obstruct flow. The precision in their manufacturing contributes significantly to the valve's effectiveness and durability, allowing it to withstand high pressures and temperatures.

The threaded aspect of these valves refers to the method used to connect them to pipe systems. Unlike welded or flanged valves, threaded ball valves utilize male or female threads for connection, providing ease of installation and maintenance. This threaded connection allows for a tight seal, which is crucial in preventing leaks and ensuring efficient operation.

Advantages of Threaded Ball Valves

One of the primary advantages of threaded ball valves is their ease of use. They can be quickly installed without the need for specialized tools, making them a favorite among technicians and operators. Furthermore, the clear open-and-close position of the valve, often indicated by a handle, allows for intuitive operation.

Another significant benefit is their versatility. Threaded ball valves can be used in various applications, including water supply, gas pipelines, and chemical processing. They can handle different types of media, including corrosive substances, as long as the material of the valve is compatible with the fluid's characteristics. This versatility makes them suitable for a broad range of industries, including food and beverage, pharmaceuticals, and HVAC systems.

threaded ball valve

Performance and Reliability

The functionality of threaded ball valves extends beyond mere flow control. They are known for their low-pressure drop, which means they can maintain efficient flow rates while minimizing energy loss. This makes them an excellent choice for systems where pressure is a critical factor.

Additionally, these valves are engineered for longevity. With fewer moving parts than other types of valves, such as gate or globe valves, threaded ball valves experience less wear and tear, which translates to increased reliability over time. Properly maintained, they can function effectively for many years, reducing the need for frequent replacements and minimizing downtime in industrial operations.

Considerations for Use

While threaded ball valves offer many advantages, there are factors to consider when selecting the right valve for a specific application. The size of the valve needs to match the diameter of the piping system, and the pressure ratings should align with the operational demands. Furthermore, it is essential to consider the material of the valve in relation to the media it will be controlling to avoid corrosion or chemical degradation.

Installation and regular maintenance are also critical to ensuring optimal performance. Threaded connections should be checked for tightness periodically, and the valve should be exercised regularly to prevent any potential sticking, especially in applications with infrequent usage.

Conclusion

In conclusion, threaded ball valves represent a formidable solution for flow control across a multitude of industrial applications. Their ease of installation, reliability, and versatility position them as a preferred choice among engineers and technicians alike. As industries continue to evolve and the demand for efficient systems increases, the role of threaded ball valves will undoubtedly remain crucial in ensuring safe and effective flow management.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025