Nov . 06, 2024 21:49 Back to list

Understanding the Functionality of Swing Type Check Valves and Their Applications

Understanding Swing Type Check Valves

Check valves are critical components in various piping systems, serving a vital function in preventing backflow and ensuring the unidirectional flow of fluids. Among the various designs of check valves, the swing type check valve is particularly prominent due to its simplicity, reliability, and effectiveness. This article delves into the mechanics, applications, advantages, and considerations related to swing type check valves.

What is a Swing Type Check Valve?

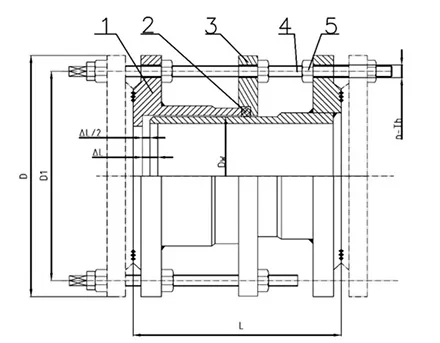

A swing type check valve is a type of one-way valve that allows fluid to flow in one direction while preventing reverse flow. Its mechanism consists of a disc that swings on a hinge. When the fluid flows in the intended direction, the disc is pushed open, allowing fluid to pass through. However, if there is a backflow, the disc swings closed under the influence of gravity and the back pressure of the fluid, effectively sealing the valve and preventing reverse flow.

Mechanics of Operation

The operation of a swing type check valve is straightforward yet effective. The disc is typically made from materials such as stainless steel, brass, or plastic, depending on the application. The hinge allows the disc to pivot freely, and its weight ensures that it returns to the closed position when backflow occurs. The design allows for minimal pressure drop across the valve, making it suitable for a wide range of applications. The valve can be installed in both horizontal and vertical orientations, providing flexibility in piping layouts.

Applications

Swing type check valves are used across various industries, including

1. Water and Wastewater Treatment In treatment plants, these valves prevent the backflow of sewage and other effluents, thereby safeguarding the integrity of the water supply. 2. Oil and Gas In oil pipelines, they prevent backflow that could lead to hazardous leaks and maintain pressure in the system. 3. HVAC Systems These valves help manage the flow of cooling and heating fluids, ensuring efficient operation. 4. Industrial Processes They are utilized in manufacturing processes where unidirectional flow is critical to system integrity and performance.

Advantages of Swing Type Check Valves

The swing type check valve offers several advantages

swing type check valve

- Low Resistance to Flow Due to their design, these valves exhibit low pressure drop, which is crucial in maintaining system efficiency. - Simplicity and Durability The simple mechanical design results in fewer parts, reducing the potential for failure and extending the valve's lifespan. - Versatility They can be used in a wide range of applications and environments, adapting to various pressure and temperature conditions.

- Cost-Effective Their straightforward design generally makes them more affordable than other check valve types, promoting their widespread use in various industries.

Considerations When Selecting a Swing Type Check Valve

While swing type check valves are advantageous, there are considerations to keep in mind

1. Installation Orientation They perform best in horizontal installations. While they can be installed vertically, care must be taken to ensure optimal function.

2. Back Pressure High back pressure can affect the closing mechanism. Therefore, evaluating the system pressure characteristics before installation is essential.

3. Fluid Characteristics The valve material should be compatible with the fluid it will handle to prevent corrosion or degradation.

4. Sizing Proper sizing is critical for both performance and reliability. An undersized valve can lead to higher pressure drops, while an oversized valve might not close properly.

Conclusion

Swing type check valves play an essential role in ensuring the efficient and safe operation of fluid systems across various industries. Their reliability, low-pressure drop, and simplicity make them a preferred choice for many applications. By understanding their mechanics, advantages, and proper usage considerations, engineers and technicians can effectively incorporate these valves into their systems, enhancing performance and preventing costly backflow issues.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025