Feb . 20, 2025 02:52 Back to list

stainless steel globe valve

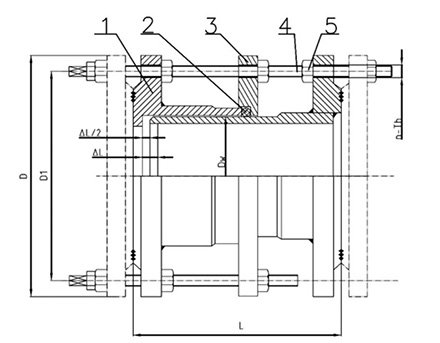

Stainless steel globe valves are integral components in the realm of fluid control, widely recognized for their durability and reliability. Frequently utilized across various industries, these valves offer a seamless way to manage the flow of liquids and gases within pipelines. Their efficacy is especially prominent in sectors such as oil and gas, chemical manufacturing, and water treatment, where precision in flow control is paramount.

The installation of stainless steel globe valves should be approached with care and precision. Employing experienced technicians for installation ensures that the valve operates correctly and efficiently within the system. Proper installation prevents common issues such as leaks or inefficient flow control, which could compromise system operations. Moreover, regular maintenance, including periodic inspections and part replacements as needed, is crucial in sustaining the valve's functionality and prolonging its service life. The credibility of stainless steel globe valves is evident through their widespread acceptance and recommendation by industry leaders and experts. Leading manufacturers provide extensive documentation and user guides, highlighting their commitment to quality and safety. These informational resources are invaluable to users, providing detailed insights into the operational aspects and maintenance of the valves, which further enhances trust and user confidence. In terms of regulatory compliance, stainless steel globe valves frequently adhere to international standards such as those from the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO). Compliance with these standards ensures that the valves meet rigorous quality and safety specifications, which is a testament to their reliability and quality assurance. Investing in stainless steel globe valves is a strategic decision that combines durability, efficiency, and reliability. Their advanced design and material composition meet the complex needs of modern industries, offering unparalleled performance in fluid control applications. By choosing stainless steel globe valves, industries not only gain a high-performance component but also foster greater operational efficiency and safety in their processes.

The installation of stainless steel globe valves should be approached with care and precision. Employing experienced technicians for installation ensures that the valve operates correctly and efficiently within the system. Proper installation prevents common issues such as leaks or inefficient flow control, which could compromise system operations. Moreover, regular maintenance, including periodic inspections and part replacements as needed, is crucial in sustaining the valve's functionality and prolonging its service life. The credibility of stainless steel globe valves is evident through their widespread acceptance and recommendation by industry leaders and experts. Leading manufacturers provide extensive documentation and user guides, highlighting their commitment to quality and safety. These informational resources are invaluable to users, providing detailed insights into the operational aspects and maintenance of the valves, which further enhances trust and user confidence. In terms of regulatory compliance, stainless steel globe valves frequently adhere to international standards such as those from the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO). Compliance with these standards ensures that the valves meet rigorous quality and safety specifications, which is a testament to their reliability and quality assurance. Investing in stainless steel globe valves is a strategic decision that combines durability, efficiency, and reliability. Their advanced design and material composition meet the complex needs of modern industries, offering unparalleled performance in fluid control applications. By choosing stainless steel globe valves, industries not only gain a high-performance component but also foster greater operational efficiency and safety in their processes.

Share

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025