Dec . 13, 2024 22:33 Back to list

ss ball valve flange type

SS Ball Valve Flange Type A Comprehensive Overview

The SS (Stainless Steel) ball valve flange type is a vital component in various industrial applications, renowned for its durability, reliability, and excellent performance in regulating fluid flow. This valve design is especially favored in systems where a secure and leak-proof connection is crucial. In this article, we will delve into the features, advantages, applications, and maintenance considerations of SS ball valve flange types.

Features of SS Ball Valve Flange Type

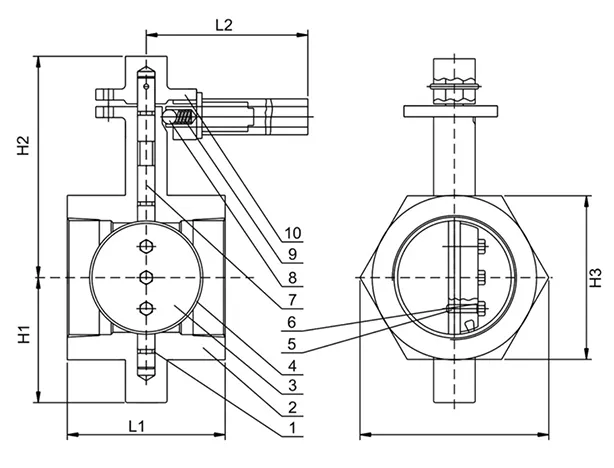

One of the primary characteristics of SS ball valves is their construction material. Stainless steel offers high resistance to corrosion, making it ideal for harsh environments where other materials might fail. The flange type refers to the valve's connection method, which uses flanges for mounting. This design allows for easy installation and maintenance, as the valve can be securely bolted to piping, ensuring a tight seal.

The SS ball valve flange type operates using a spherical disc or ball that rotates within the valve body to control flow. When the ball is turned to align with the flow path, the valve is open, allowing fluid to pass through. Conversely, when the ball is rotated 90 degrees, the flow is blocked. This simple yet effective mechanism allows for quick operation, often referred to as quarter-turn valves.

Advantages of SS Ball Valve Flange Type

The use of SS ball valves with flange connections comes with a myriad of benefits

1. Corrosion Resistance As mentioned earlier, stainless steel is highly resistant to rust and corrosion, making these valves suitable for a wide range of chemicals and environments, including those found in the oil, gas, and water treatment industries.

3. Ease of Maintenance The flange design facilitates straightforward installation and disassembly, allowing for efficient maintenance and servicing without the need to remove entire sections of piping.

ss ball valve flange type

4. Minimal Flow Resistance The ball valve's design allows for a straight-through flow path when open, minimizing pressure drop and turbulence, which helps maintain efficient system operations.

5. Versatility These valves are suitable for a variety of applications, including liquids, gases, and even slurries. Their adaptability makes them popular in many industries, such as power generation, food and beverage, pharmaceuticals, and chemicals.

Applications

SS ball valve flange types find their use in numerous sectors

- Oil and Gas They are crucial in controlling the flow of oil and natural gas in pipelines and processing plants. - Water Treatment These valves help regulate water flow in treatment plants, ensuring efficient operation and safety. - Chemical Processing Used to manage the flow of various chemicals, their corrosion resistance is vital in these applications. - Food and Beverage Hygienic designs of SS ball valves meet stringent safety standards, making them ideal for food processing and beverage manufacturing. - Pharmaceuticals Ensuring the integrity of products, these valves are used in processes that require strict compliance with health regulations.

Maintenance Considerations

To ensure optimal performance and longevity, routine maintenance of SS ball valve flange types is essential. Here are some key practices

- Regular Inspection Periodically check for signs of wear, corrosion, or leakage. Early detection of issues can prevent more significant problems later on. - Cleaning Keep the valve clean to prevent buildup of debris that could affect its operation. For sensitive applications, special cleaning agents may be necessary. - Lubrication Regularly lubricate moving parts to ensure smooth operation and prevent seizing. - Tightening Flanges Ensure that flange bolts are properly tightened, as vibrations and thermal expansion can lead to loosening over time.

Conclusion

The SS ball valve flange type is an essential component in modern industrial systems, offering superior benefits in terms of durability, ease of maintenance, and versatility. Its robust design allows it to excel in various demanding environments, making it a preferred choice for professionals across multiple sectors. By understanding the features and applications of these valves, industries can leverage their advantages for improved efficiency and safety in fluid management. Proper maintenance practices will further enhance their functionality, ensuring long-lasting performance that meets the requirements of any challenging application.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025