Sep . 28, 2024 20:22 Back to list

Understanding Socket and Resilient Seated Gate Valve Applications and Benefits

Understanding Socket and Resilient Seat Gate Valves

In the realm of fluid control and management systems, valves play an essential role in regulating flow and maintaining pressure within pipelines. Among these, the socket and resilient seat gate valves are particularly noteworthy for their unique structure and functionality. This article aims to discuss these types of valves, highlighting their features, applications, advantages, and maintenance practices.

What are Socket and Resilient Seat Gate Valves?

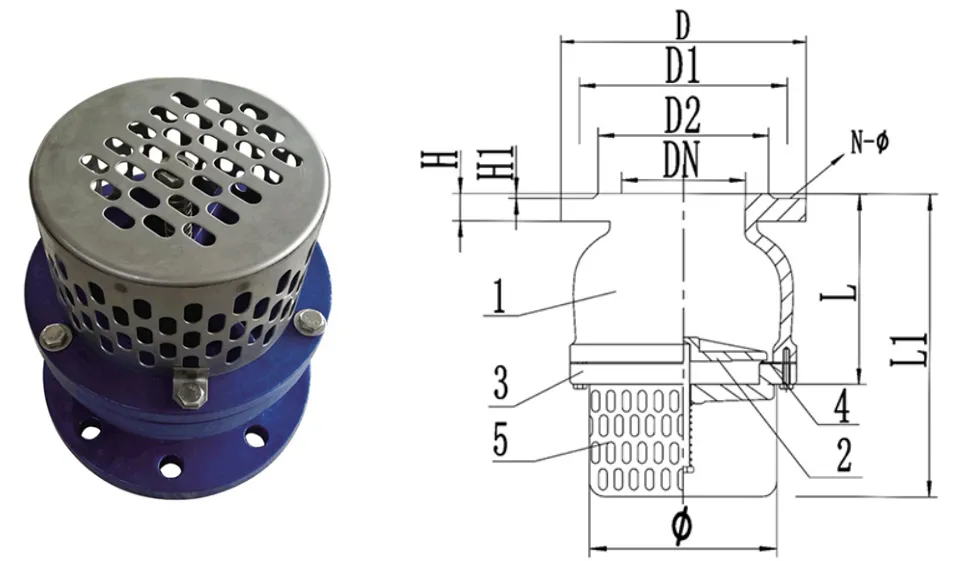

Socket and resilient seat gate valves are types of valves specifically designed to provide a tight seal and to facilitate the on-off control of fluid flow. The term socket refers to the mechanism by which the valve connects to pipes. This connection is typically achieved through the use of a socket weld, which ensures a secure fit and minimizes the risk of leakage.

The resilient seat aspect is critical to how these valves operate. Unlike traditional metal seats that can wear out over time, resilient seats are usually constructed from elastomers or other flexible materials. This feature allows the valve to form a better seal against the gate, reducing the likelihood of leaks when the valve is closed. Additionally, resilient seat valves are designed to withstand varying pressure levels and temperatures, making them versatile in application.

Key Characteristics

- Construction Socket and resilient seat gate valves are generally made from durable materials such as ductile iron, stainless steel, or bronze. The choice of materials affects their performance in different environments, especially with corrosive fluids. - Design The design typically includes a gate, a body, a bonnet, and a sealing mechanism. The gate moves vertically to either block or allow fluid flow, while the resilient seat compresses against the gate, ensuring a tight seal. - Operation These valves can be operated manually using a handwheel or can be automated using electrical or pneumatic actuators. Automated options are particularly beneficial in applications requiring remote control or integration with digital systems.

Applications

Socket and resilient seat gate valves are widely used in various industries due to their reliability and effectiveness

. Common applications includesocket and resilient seat gate valve

- Water Supply and Distribution They play a crucial role in municipal water systems, where the ability to stop and start flow is essential for maintenance and emergency situations. - Wastewater Treatment These valves help control the flow of wastewater and are designed to handle the specific challenges associated with such environments. - Oil and Gas In the energy sector, they manage the flow of crude oil and gas, where strong, leak-resistant connections are paramount. - HVAC Systems The valves regulate water flow in heating, ventilation, and air conditioning systems, contributing to energy efficiency and comfort.

Advantages

The advantages of socket and resilient seat gate valves are notable, including

1. Leak-Free Performance The resilient seat design provides enhanced sealing capability, significantly reducing the risk of leaks. 2. Durability Made from high-quality materials, these valves have long service lives, even in harsh environments. 3. Ease of Installation The socket connection simplifies installation processes, allowing for quick and efficient assembly with minimal tools. 4. Maintenance These valves require relatively low maintenance due to their robust design. Regular inspection and servicing can prolong their life span significantly.

Maintenance Practices

To ensure optimal performance of socket and resilient seat gate valves, some essential maintenance practices include

- Regular Inspections Check for signs of wear, leakage, or buildup of materials that may impede operation. - Cleaning Regularly clean the valve body and surrounding area to remove any debris or sediment that could affect functionality. - Lubrication Maintain proper lubrication of mechanical parts to prevent friction and wear.

Conclusion

Socket and resilient seat gate valves are vital components in various fluid control systems, offering a combination of durability, reliability, and ease of use. Their robust design and effective sealing capabilities make them indispensable in a multitude of industries, from water supply to oil and gas. Proper maintenance will ensure these valves function efficiently, reducing downtime and operational costs. As industries continue to evolve, the demand for high-performance valve solutions like socket and resilient seat gate valves is likely to grow, highlighting their importance in modern engineering and infrastructure.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025