Nov . 05, 2024 05:19 Back to list

socket and resilient seat gate valve

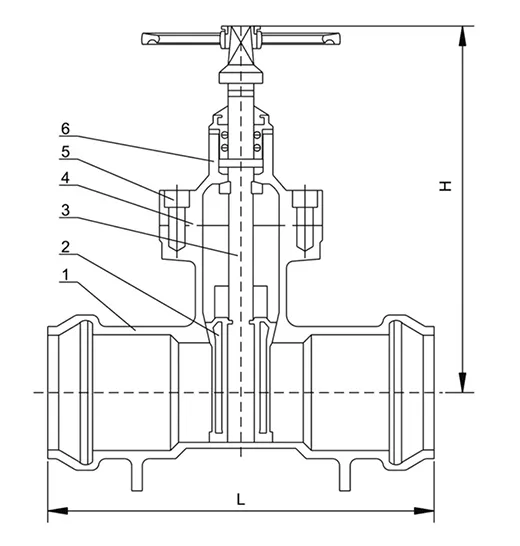

The Socket and Resilient Seat Gate Valve An Overview

When it comes to fluid management in industrial applications, the choice of valves is crucial for ensuring efficiency and reliability. Among the array of valve types available, the socket and resilient seat gate valve has gained recognition for its innovative design and practical functionality. This article delves into the features, applications, and advantages of socket and resilient seat gate valves, revealing why they are a preferred choice in various industries.

Features of Socket and Resilient Seat Gate Valves

Socket and resilient seat gate valves are designed to provide a tight seal, minimizing leakage and ensuring effective control over fluid flow. One key characteristic is the resilient elastomer seat, which allows for a superior sealing mechanism compared to traditional metal seats. This resilient material can accommodate slight misalignments, reducing wear and prolonging valve life.

The valve's socket connection simplifies installation and maintenance. With a straightforward design that utilizes a socket weld, these valves can be easily integrated into pipe systems without requiring extensive modifications. The simplicity of installation also contributes to reduced labor costs and time, making these valves an economical choice for many applications.

Applications

Socket and resilient seat gate valves are widely used across various sectors, including water supply, wastewater management, chemical processing, and HVAC systems

. Their robust design is particularly advantageous in environments where pressure fluctuations and temperature variations are common.In water and wastewater treatment facilities, these valves are essential for controlling the flow of liquids, preventing backflow, and safeguarding against contamination. Their ability to handle high flow rates makes them suitable for irrigation systems, where they help manage the distribution of water efficiently.

socket and resilient seat gate valve

Chemical processing industries benefit from the reliability of socket and resilient seat gate valves, as these valves can withstand aggressive fluids and corrosive substances. Moreover, their easy maintenance routine ensures that operational downtime is minimized, which is vital in a fast-paced production environment.

Advantages

The advantages of socket and resilient seat gate valves are numerous. Firstly, the resilient seat not only enhances the sealing capability but also provides higher durability against wear and tear caused by fluid turbulence. This durability translates into reduced maintenance costs over time, making them a practical investment.

Secondly, the design of these valves allows for smooth and uninterrupted flow when fully open, resulting in minimal pressure drop across the valve. This characteristic is crucial in applications that require maintaining system efficiency without imposing additional energy costs.

Another significant advantage is their versatility. With various sizes and pressure ratings available, socket and resilient seat gate valves can be customized to meet specific requirements, allowing for broad applicability across different systems.

Conclusion

In conclusion, socket and resilient seat gate valves represent a perfect blend of innovation and functionality. Their unique design, combined with their ease of installation and maintenance, positions them as a prime choice for industries reliant on effective fluid management. By utilizing these valves, companies can enhance their operational efficiency, reduce long-term costs, and ensure the safety and reliability of their systems. As industries continue to evolve and seek out robust solutions for fluid control, the popularity of socket and resilient seat gate valves is likely to grow, solidifying their place as essential components in modern engineering.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025