Sep . 23, 2024 03:03 Back to list

severe service

Understanding Severe Service in Industrial Applications

In the realm of industrial applications, the term severe service describes a specific set of operational conditions characterized by extreme environments, high pressures, elevated temperatures, and abrasive or corrosive substances. Equipment and components used in severe service conditions must be designed and manufactured to withstand these challenging scenarios, ensuring reliability, safety, and long-term performance.

Severe service can be found in various industries, including oil and gas, chemical processing, power generation, and mining. Each of these sectors presents unique challenges that necessitate specialized designs and materials. For instance, in the oil and gas industry, components must endure cyclic loading, extreme temperatures, and aggressive chemical environments, all of which can lead to premature wear and failure if not addressed properly.

The importance of selecting the right materials cannot be overstated when designing equipment for severe service conditions

. Failure to account for environmental factors can lead to costly downtime, safety hazards, and significant financial losses. This is where material science and engineering play a critical role. Advanced alloys, high-performance polymers, and coatings are often employed to enhance the durability and performance of these components. For example, stainless steel may be used in applications where corrosion is a significant concern, while specialized coatings can protect surfaces from wear and erosion.severe service

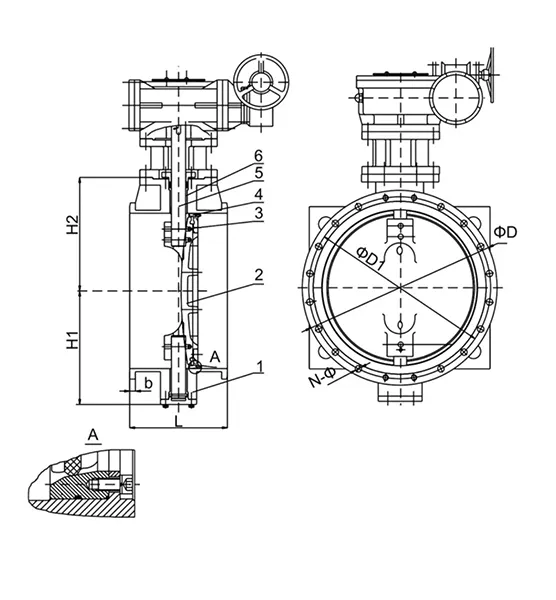

Design considerations in severe service applications also extend to the overall system configuration. For instance, valves and pumps operating in harsh environments must be designed to prevent leaks and maintain optimal flow rates under varying pressures and temperatures. Additionally, redundancy in critical components may be implemented to ensure that systems remain operational even in the event of a failure.

Another aspect to consider is the impact of operational parameters. Severe service requires continuous monitoring and maintenance to ensure that all equipment functions as intended. Predictive maintenance strategies, utilizing advanced sensors and data analytics, are increasingly employed to detect potential issues before they escalate into serious problems. This proactive approach can significantly minimize downtime, extend the lifecycle of equipment, and improve overall efficiency.

Furthermore, the implications of severe service extend beyond individual components to influence the overall safety and environmental sustainability of industrial operations. For example, the failure of a valve in a processing plant could lead not only to operational disruptions but also to hazardous chemical spills that pose risks to workers and the environment. Thus, understanding the principles of severe service is critical for engineers, operators, and safety personnel alike.

In conclusion, severe service represents a challenging but essential aspect of many industrial processes. Through careful material selection, innovative designs, and rigorous maintenance practices, enterprises can effectively manage the risks associated with severe environments. By prioritizing durability and reliability, organizations can ensure their operations continue to run smoothly, ultimately leading to enhanced productivity and safety. As industries evolve and face new challenges, the importance of expertise in severe service applications will only continue to grow, highlighting the need for ongoing research and development in this vital field.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025