Nov . 12, 2024 13:16 Back to list

rubber lined butterfly valve

Understanding Rubber Lined Butterfly Valves A Comprehensive Overview

Butterfly valves are pivotal components in various industrial applications due to their simple design and efficient functionality. Among the different types of butterfly valves, rubber lined butterfly valves stand out for their unique features and benefits, making them a preferred choice for many processes, especially where fluid flow control, sealing integrity, and resistance to various environmental factors are critical.

What is a Rubber Lined Butterfly Valve?

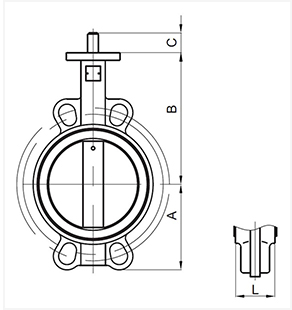

A rubber lined butterfly valve is a type of quarter-turn valve that uses a rubber liner to enhance its sealing capability and protect the valve body. Unlike traditional metal-bodied valves, the rubber lining provides a barrier against corrosive fluids and helps prevent leakage. These valves are composed of a disc that pivots around a central axis and a seat lined with rubber material, allowing for smooth operation and effective flow regulation.

Key Features and Advantages

1. Corrosion Resistance One of the primary reasons for using rubber lined butterfly valves is their exceptional resistance to corrosion. The rubber lining protects the valve from aggressive fluids, making them suitable for industries such as wastewater treatment, chemical processing, and food and beverage production.

2. Effective Sealing The rubber lining enhances the seal between the valve disc and the seat, ensuring minimal leakage during operation. This is particularly advantageous in applications that require strict adherence to fluid containment standards, such as in pharmaceutical manufacturing.

3. Lightweight and Compact Design Rubber lined butterfly valves are generally lighter than their metal counterparts, making them easier to install and maintain. Their compact design allows for installation in tight spaces, which is often necessary in modern industrial setups where space is at a premium.

rubber lined butterfly valve

4. Cost-Effectiveness When compared to fully metal valves, rubber lined butterfly valves are often more economical due to lower manufacturing and maintenance costs. The reduced need for repairs and replacements over time adds to their overall cost-effectiveness.

5. Wide Range of Applications These valves are versatile and can be used in various applications, including but not limited to, water treatment plants, HVAC systems, and oil and gas industries. Their ability to handle different types of fluids, including slurries and gases, further expands their usability.

6. Simple Operation The quarter-turn mechanism of butterfly valves ensures that they are easy to operate. This can be particularly advantageous in large installations where quick adjustments to fluid flow are necessary.

Installation and Maintenance

To ensure optimal performance, proper installation and maintenance of rubber lined butterfly valves are essential. The installation should be done according to the manufacturer's guidelines to ensure a perfect seal. Regular inspections should be conducted to check for any signs of wear or damage to the rubber lining, as deterioration can lead to leakage.

Maintenance typically involves cleaning the valves and checking the operation mechanisms for any signs of corrosion or fouling. It is also important to monitor the valve’s sealing performance over time and replace any degraded components to maintain efficiency.

Conclusion

Rubber lined butterfly valves represent a vital technology in fluid control systems across various industries. Their unique features, including corrosion resistance, effective sealing, and cost-effectiveness, make them an excellent choice for many applications. As industries continue to evolve, the demand for reliable and efficient flow control solutions will increase, solidifying the role of rubber lined butterfly valves. Whether in municipal, industrial, or commercial applications, investing in high-quality rubber lined butterfly valves can ensure improved operational efficiency, reduced leaks, and compliance with regulatory standards. By understanding these valves, industries can make informed decisions, ultimately leading to enhanced performance and sustainability in their operations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025