Sep . 28, 2024 17:40 Back to list

Exploring the Benefits of Rising Stem Globe Valves in Industrial Applications

The Rising Stem Globe Valve An Essential Component in Fluid Control

In the realm of fluid control systems, valves play a pivotal role in regulating the flow, pressure, and direction of liquids and gases. Among the various types of valves available, the rising stem globe valve stands out due to its unique design and operational advantages. This article will explore the characteristics, applications, and benefits of rising stem globe valves, emphasizing their importance in industrial processes.

Design and Functionality

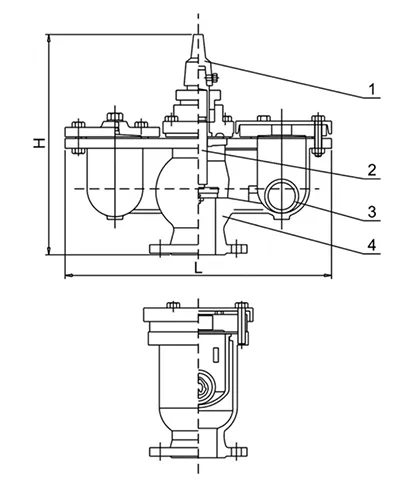

The rising stem globe valve features a distinctive construction that sets it apart from other types of valves. Its main components include a valve body, a movable disk or plug, and a stem that rises when the valve is opened. The design allows the operator to visually confirm the position of the valve — whether it is open or closed — as the stem extends upward when the valve is in an open state. This feature provides an added layer of safety and convenience, particularly in applications where visual checks are essential.

One of the primary functions of a rising stem globe valve is to provide precise flow regulation. The disk or plug design allows for fine adjustments, making it an excellent choice for applications requiring modulating flow. The globe valve's structure helps to reduce turbulence and pressure loss, ensuring that fluids flow smoothly through the system.

Applications

Rising stem globe valves are widely used across various industries, including oil and gas, water treatment, power generation, and chemical processing. In the oil and gas industry, these valves are typically used in pipeline and pump control systems to regulate the flow of crude oil or natural gas. Their capability to handle high pressures and temperatures makes them suitable for demanding environments.

rising stem globe valve

In water treatment facilities, rising stem globe valves are used to control the flow of water in filtration and disinfection processes. They ensure that the correct amount of water is treated efficiently, contributing to the overall effectiveness of the plant. Similarly, in power generation, these valves are crucial in steam and water systems, where precise flow control is essential for optimizing energy production.

Advantages

One of the most significant advantages of using rising stem globe valves is their durability. Constructed from robust materials such as stainless steel, cast iron, or bronze, these valves can withstand harsh environmental conditions, including extreme temperatures and corrosive substances. Their longevity and reliability contribute to reduced maintenance costs and extended operational lifespans.

Additionally, the design of rising stem globe valves allows for a high degree of sealing capability. When closed, the plug forms a tight seal against the seat, minimizing the risk of leaks. This feature is particularly important in applications where fluid leakage can lead to safety hazards, environmental concerns, or economic losses.

Another benefit is the ease of maintenance. The straightforward design of rising stem globe valves allows for easy disassembly and reassembly, which can be accomplished without removing the valve from the piping system. This accessibility empowers maintenance personnel to perform inspections and repairs efficiently, resulting in minimal downtime for operations.

Conclusion

In summary, rising stem globe valves are indispensable elements in various fluid control systems, cherished for their precise flow regulation, durability, and ease of maintenance. Their unique design not only enhances operational safety but also maximizes efficiency across diverse industrial applications. As industries continue to evolve and expand, rising stem globe valves will undoubtedly remain a trusted choice for managing fluid flow effectively, ensuring the smooth functioning of vital processes worldwide.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025