Sep . 22, 2024 11:37 Back to list

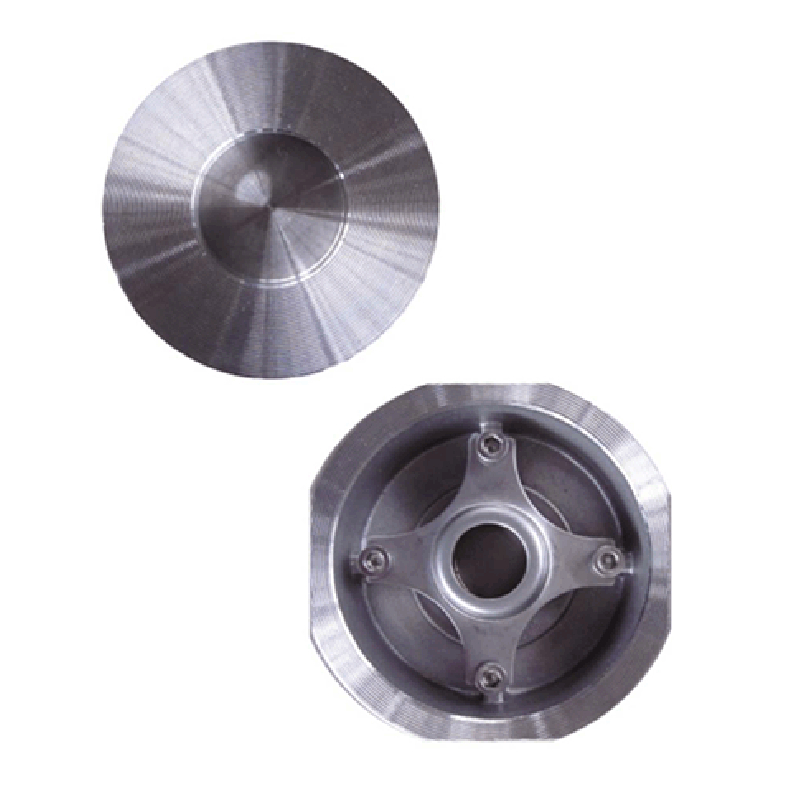

pneumatic ball valve

Understanding Pneumatic Ball Valves A Comprehensive Overview

Pneumatic ball valves are essential components in various industrial applications, providing reliable control of fluid flow. Their robust design and efficient operation make them indispensable in systems requiring precise regulation of gas and liquid movement. This article delves into the fundamental features, advantages, and applications of pneumatic ball valves, offering insight into why they are favored in many industries.

At the core of a pneumatic ball valve is a spherical disc, or ball, with a hole through its center. This design allows for straightforward on/off flow control. When the valve is in the open position, the hole aligns with the flow path, enabling fluid to pass through freely. Conversely, when the valve is closed, the ball rotates 90 degrees, blocking the flow. The simplicity of this mechanism results in low pressure drop and minimal turbulence, making it ideal for various applications.

One of the primary advantages of pneumatic ball valves is their rapid actuation. With a pneumatic actuator connected to the valve, it can open or close within seconds, enhancing operational efficiency. This speed is particularly beneficial in automated systems where quick response times are crucial. Additionally, pneumatic systems are less prone to electrical hazards, making them suitable for environments where sparks could pose risks.

Another noteworthy feature of pneumatic ball valves is their ability to handle high pressures and temperatures

. This resilience makes them a preferred choice in industries such as oil and gas, chemical processing, and power generation. Moreover, most pneumatic ball valves are designed with durable materials, such as stainless steel or reinforced plastic, providing longevity and reliability even in demanding conditions.pneumatic ball valve

The versatility of pneumatic ball valves is evident in their wide range of applications. In the chemical industry, they are used for controlling the flow of corrosive substances, while in HVAC systems, they regulate airflow efficiently. In food and beverage processing, hygiene is paramount, and pneumatic ball valves can be constructed to meet stringent cleanliness standards, ensuring safe and uncontaminated products.

Installation and maintenance of pneumatic ball valves are relatively straightforward. They can be easily integrated into existing systems, and their mechanical simplicity often translates to lower maintenance requirements. Regular inspections and routine lubrication are generally sufficient to keep them functioning optimally, reducing downtime and operational costs.

Moreover, the advancements in technology have led to the development of smart pneumatic ball valves, which incorporate sensors and automation, allowing for enhanced monitoring and control. These innovations enable operators to track performance metrics in real time, optimizing processes and improving safety.

In conclusion, pneumatic ball valves are vital components in modern industrial applications, offering reliable, efficient, and safe control of fluid flow. Their rapid actuation, durability, and versatility make them a top choice across various sectors. As technology continues to evolve, the future of pneumatic ball valves looks promising, with further innovations anticipated to enhance their functionality and ease of use. Understanding these valves is crucial for anyone involved in fluid dynamics, automation, or industrial operations, ensuring they can make informed decisions about their deployment and maintenance.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025