Jul . 29, 2025 11:00 Back to list

Pipe Expansion Joint Types for All Applications | PVC, HDPE, DI & Universal Solutions

Engineered piping systems demand flexibility, durability, and high-quality joining technology to ensure operational safety and cost-efficiency across sectors—including petrochemical, metallurgy, and water supply. Pipe expansion joint types play a pivotal role in absorbing movements, vibrations, and stresses, while advanced solutions like Dismantling Joint (product details) offer next-generation flexibility and system reliability.

Industry Evolution & Trend Analysis: Pipe Expansion Joint Types

As global infrastructure modernizes, pipe joint selection is critical to system performance. The demand for specialized pipe expansion joint types is driven by:

- Increasing adoption in water transmission and sewage treatment, projected CAGR 6.1% by 2029 (Source: Grand View Research)

- Requirements for anti-corrosion, vibration resistance, and energy efficiency per ISO 9001:2015 and ANSI/AWWA C219

- Growth in large-scale industrial pipelines, e.g., China's water networks, Middle East Oil projects

- Advances in materials science: introduction of duplex stainless steel, EPDM, and composite alloys

| Type | Material | Standard Sizes (mm) | Pressure Rating (bar) | Common Applications |

|---|---|---|---|---|

| Metal Bellows Joint | SS304, SS316L, Inconel | 50-2000 | 10-40 | Steam, Petrochemical |

| Rubber Expansion Joint | EPDM, NBR, PTFE | 32-3000 | 6-25 | Water supply, HVAC |

| Fabric Expansion Joint | Glass fabric, PTFE | 150-6000 | 0.1-2 | Gases, Ducting (power plants) |

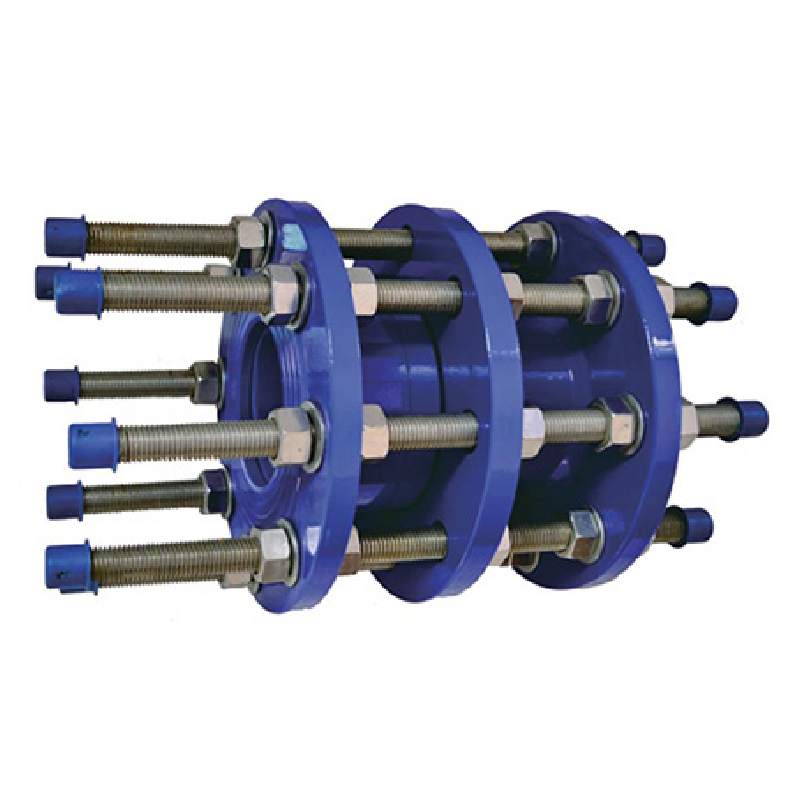

| Gland Dismantling Joint | Ductile Iron, Carbon Steel | 80-2400 | 10-25 | DI pipe, water treatment |

| PVC Joint Types | PVC, UPVC | 20-500 | 6-16 | Water, Irrigation |

| HDPE Pipe Joint Types | HDPE, PP | 25-1200 | 6-25 | Gas, Sewer, Water |

| DI Pipe Joint Type | Ductile Iron | 80-2400 | 10-25 | Municipal pipelines |

| Universal Joint Types | Steel, Stainless Steel | 15-500 | 10-32 | Alignment adjustment, repairs |

*Market data collated from Grand View Research, Sandler Research, and Valve-Cable.com export analytics.

Manufacturing Process: Dismantling Joint & Pipe Expansion Joint Types

Robust performance in pipeline expansion joints arises from controlled manufacturing and rigorous testing—key to longevity and safety.

Raw Material Selection Casting & Forging (for DI & steel) CNC Machining Assembly (Seals, Body, Flanges, Bolts) NDE Testing (ISO/ANSI, pressure, corrosion) Surface Coating (Fusion Bonded Epoxy, Galvanization) Final Inspection & Dispatch

- Key Standards Applied: ISO 7005, EN 14525, ANSI/AWWA C219

- Inspection Points: Wall thickness, leak tightness, dimensional accuracy, coating thickness

- Typical Service Life: 30-50 years (Ductile Iron, Coated DI, HDPE systems)

For an animated illustration, see [Pipe Joint Assembly Video]

- Cast Iron/Ductile Iron (DI): High tensile strength (>420 MPa), excellent corrosion resistance when coated; core for DI pipe joint type.

- HDPE & PVC: Lightweight, low friction, chemical inertness; used in hdpe pipe joint types and pvc joint types across water and chemical industries.

- Elastomers (EPDM, NBR): Used in sealing seats for universal joints and bellows, per ISO 4633.

| Parameter | Dismantling Joint | DI Flange Adapter | Universal Coupling |

|---|---|---|---|

| Material Grade | Ductile Iron (EN-GJS-500-7), Epoxy coated | DI/Steel, Epoxy | SS304/316, DI |

| Nominal Diameter Range | DN80-DN2400 | DN40-DN2000 | DN50-DN600 |

| Working Pressure | PN10/16/25 (up to 25 bar) | PN10/16/25 | PN10/16 |

| Test Pressure | 1.5× Working Press. | 1.5× WP | 1.5× WP |

| Corrosion Protection | Fusion Bonded Epoxy ≥ 250μm | Epoxy ≥200μm | Zn/EP Coating |

| Sealing Material | EPDM/NBR/NR (ISO 4633) | EPDM/CR | EPDM/CR |

| Service life (years) | 40+ | 35+ | 30+ |

| Certifications | ISO 2531, WRAS, DVGW | ISO, WRAS | ISO, DVGW |

Technical Advantages of Modern Pipe Expansion Joint Types

- Outstanding Energy Absorption: Compensate for axial/lateral displacements, pipeline settlement, and vibration—vital for seismic zones.

- Corrosion & Abrasion Resistance: Advanced coatings (ISO 21809-2) and material selection significantly prolong lifespan in harsh liquid environments.

- Quick Installation: Prefabricated assembly, Dismantling Joint structure enables rapid maintenance, reducing downtime by 70%.

- Universal Compatibility: Suits steel, DI, HDPE, and even PVC pipe systems; standardized per EN 14525.

- Cost-Effectiveness: Lower lifecycle cost (TCO) versus rigid connections; compatible with refurbishment projects.

| Manufacturer | Region | Core Product | Certifications | Major Clients | Service Years |

|---|---|---|---|---|---|

| Valve-Cable | China/EU | Dismantling Joint | ISO 9001, ISO 2531, WRAS | Suez, Veolia, Saudi Aramco | 20+ |

| VAG Group | Germany | Gland Dismantling Joints | DVGW, ISO, CE | Siemens, BASF, local govts | 50+ |

| Straub | Switzerland | Universal Couplings | SCC, ISO | ABB, E.On, Shell | 40+ |

| AVK | Denmark | Flexible Joints | ISO, EN 545 | Global Water, Thames Water | 35+ |

| Kurimoto | Japan | Expansion Joints, Adapters | ISO, JIS | Tokyo Gas, local utilities | 60+ |

Customization Solutions & Engineering Support

- Engineering Design: Bespoke sizes (DN80-DN2400), pressure ratings, materials (Duplex, DI, HDPE) for complex pipeline geometries

- Site-Specific Coatings: Chemical/sea water resistance with FBE, Rilsan, or hot-dip galvanization options

- Fast Track Delivery: Typical lead time 14–28 days; on-site installation support worldwide for special projects

- Joint Integrity Validation: 100% hydrotest, radiographic (X-ray) and NDE ultrasonic inspection per ASTM E165

Challenge: High-velocity DI pipeline (PN16, DN1600mm), risk of thermal elongation and seismic movement.

Solution: Dismantling Joint and rubber expansion joints deployed at every 80m interval. System absorbed up to ±80mm axial displacement.

Outcome: No leak or failure for 8+ years; reduced scheduled maintenance by 55%. Saudi Aramco project team endorsed solution per corporate technical standards.

Application Scenarios: Pipe Expansion Joint Types in the Field

- Petrochemical Plants: Compensate for thermal movement, prevent pipeline cracks, apply to both buried and aboveground systems

- Municipal Water Supply: Enable maintenance without pipeline disassembly; key for DI, HDPE, and PVC networks

- Power Generation: Reduce vibration damage in turbine cooling systems (per ASHRAE guidelines)

- Metallurgy: Protect against mechanical fatigue, especially under cyclic loads and corrosive fluids

- Infrastructure Refurbishment: Upgrade legacy systems with universal/dismantling joints for rapid fit-out

Frequently Asked Technical Questions (FAQ)

- Standard delivery: 14–28 working days from order confirmation; express service available for urgent projects.

- Warranty: 3–5 years standard (extendable), includes on-site assessment and defect replacement.

- Technical support: 24/7 consultation; on-site installation and training by certified service teams for key accounts.

- After-sales: Documented test reports, certification package, and global customer service contact for warranty claims.

Explore Further & Professional Resources

- For technical drawings, specification guides, and case documentation: pip expansion joint types – Valve-Cable product hub

- Standards and best practices: AWWA (American Water Works Association), ISO 9001:2015

- Industry forum discussions: Eng-Tips - Expansion Joints

- Peer-reviewed articles: ASCE Library - Pipe Joint Design

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025