Oct . 06, 2024 12:10 Back to list

mss glove valve

Understanding MSS GLOVE VALVE A Comprehensive Overview

The MSS glove valve, an essential component in various industrial applications, serves a critical role in controlling fluid flows. Known for their robust design and reliability, glove valves are favored in industries such as oil and gas, chemical processing, and water treatment. This article delves into the key features, benefits, and applications of MSS glove valves, providing a comprehensive understanding of their significance in modern engineering.

What is a MSS Glove Valve?

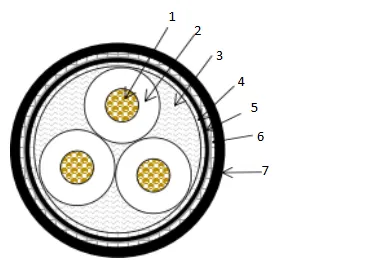

The MSS glove valve, also referred to as a globe valve, is a type of valve that regulates flow in a pipeline by using a movable disk (or plug) and a stationary ring seat. The design allows for precise control over the flow rate and direction of fluids, making it suitable for various systems, especially those requiring tight shut-off capabilities. The term glove is derived from the shape of the valve body, which resembles a glove.

Key Features of MSS Glove Valve

1. Design and Construction MSS glove valves are characterized by a linear motion stem and a spherical body. They are typically constructed from high-quality materials such as stainless steel, carbon steel, and other alloys, ensuring durability and corrosion resistance.

2. Flow Control One of the primary advantages of the glove valve is its ability to provide excellent throttling capabilities. The design allows for significant control over flow rates, making it ideal for applications where precise adjustments are necessary.

3. Versatility These valves can handle a wide range of media, including gases, liquids, and slurries. Their adaptability makes them suitable for different industries, from high-temperature steam systems to cryogenic applications.

4. Pressure Ratings MSS glove valves are available in various pressure ratings and sizes. This flexibility allows engineers to select the appropriate valve for specific operational requirements, ensuring safety and efficiency.

mss glove valve

5. Ease of Maintenance The straightforward design of glove valves facilitates easy maintenance and repair. With fewer moving parts compared to other valve types, routine inspections and component replacements can be performed with minimal downtime.

Applications of MSS Glove Valve

MSS glove valves are widely used in several applications, including

- Oil and Gas Industry In upstream and downstream operations, maintaining flow control and managing pressure is paramount. MSS glove valves are utilized in pipelines, refineries, and offshore platforms.

- Chemical Processing The ability to handle corrosive materials and extreme temperatures makes MSS glove valves ideal for chemical processing plants. They are used in reactors, separators, and distillation units.

- Water Treatment Facilities These valves assist in managing the flow of water and waste in treatment plants, ensuring effective purification processes and compliance with environmental regulations.

- Power Generation In power plants, glove valves are employed to control steam and water flow, contributing to efficient energy generation.

Conclusion

In summary, the MSS glove valve stands out as a reliable and versatile solution for flow control across various industries. Its robust design, effective throttling capabilities, and ease of maintenance make it indispensable in applications where precision is crucial. As industries continue to evolve, the significance of MSS glove valves will undoubtedly remain, ensuring safe and efficient operations in fluid management. Understanding these valves is essential for engineers and professionals tasked with designing and maintaining industrial systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025