Dec . 07, 2024 04:33 Back to list

motorized knife gate valve

Introduction to Motorized Knife Gate Valves

Motorized knife gate valves are essential components in various industrial applications where precise control of flow is required. Specifically designed for handling thick, viscous, and slurry-like materials, these valves play a crucial role in managing the flow of liquids and solids through pipelines and channels. Their unique design and operation make them ideal for industries such as wastewater treatment, mining, power generation, and food processing.

Design and Structure

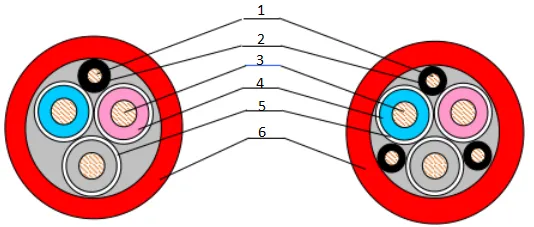

The basic structure of a knife gate valve consists of a robust body with a blade-like gate that can cut through materials. The valve is generally installed in-line and can be opened or closed using a motorized actuator. This actuator can be electrically or pneumatically powered, allowing for remote operation and automated control.

The knife gate design minimizes turbulence and resistance, which is particularly beneficial in applications where the material flow contains large particles or fibrous content. The gate itself is usually constructed from strong materials such as stainless steel or cast iron, providing durability and resistance to corrosion. Additionally, the valves often feature a self-cleaning design, which reduces maintenance efforts and prolongs service life.

Advantages of Motorized Knife Gate Valves

1. Precision Control The motorized feature of the knife gate valve allows for accurate and responsive control over the flow rates of liquids and solids. This is particularly advantageous in processes where exact material handling is crucial.

2. Reduction in Manual Labor With motorized operation, the need for manual valve operation is significantly reduced. This not only increases efficiency but also enhances safety by minimizing human involvement in potentially hazardous environments.

3. Durability Knife gate valves are built to withstand aggressive and abrasive materials. Their robust construction ensures longevity, reducing the frequency and costs associated with replacements or repairs.

4. Versatility These valves are suitable for various applications across multiple industries, including those dealing with slurries, pulp, and paper, as well as chemicals. Their adaptability makes them a popular choice for many engineering solutions.

motorized knife gate valve

Applications

Motorized knife gate valves are widely used in specific areas such as

- Wastewater Treatment Plants They help control the flow of sludge and other thick materials, ensuring efficient processing of wastewater.

- Mining Operations In the mining industry, these valves manage the flow of slurry and ore, facilitating the movement of materials from one stage of processing to another.

- Power Generation The valves are crucial in controlling flue gas desulfurization processes and the handling of biomass or coal.

- Food Processing In this sector, knife gate valves are employed for managing viscous food products, ensuring hygiene and safety in material handling.

Conclusion

Motorized knife gate valves are integral to many industrial processes, providing a reliable solution for controlling the flow of challenging materials. Their robust construction, precision control capabilities, and adaptability to various applications make them an asset in modern manufacturing and processing environments. As industries continue to evolve, the role of motorized knife gate valves will remain pivotal in enhancing operational efficiency and ensuring the safe handling of materials. Investing in these valves can yield significant benefits, from improved productivity to reduced operational costs, making them an essential component in the quest for efficient and reliable industrial processes.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025