Dec . 16, 2024 04:57 Back to list

Actuated Gate Valve Solutions for Efficient Control and Automation in Fluid Systems

Introduction to Motorized Gate Valves Principles and Applications

Motorized gate valves, a critical component in various industrial applications, are designed to control fluid flow through piping systems. Unlike manual valves that require human intervention, motorized gate valves utilize electric motors for automated operation, making them essential in processes where precision and efficiency are paramount. This article explores the principles, benefits, applications, and maintenance of motorized gate valves.

Principles of Operation

Gate valves are characterized by their simple design and functionality. They consist of a flat closure element (the gate) that moves vertically to open or close the flow path. When the valve is fully open, the gate is positioned entirely out of the fluid path, resulting in minimal resistance and pressure drop. The motorized aspect introduces an actuator that provides a reliable means of controlling the valve's position without manual effort.

The actuator can be either electric, pneumatic, or hydraulic. Electric actuators are commonly used due to their ease of integration with control systems. The actuation mechanism allows for precise positioning, enabling operators to adjust the flow rate accurately. Additionally, these valves can be operated remotely, enhancing safety and efficiency in hazardous environments.

Benefits of Motorized Gate Valves

1. Automation One of the most significant advantages of motorized gate valves is automation. They can be integrated into advanced control systems, allowing for remote monitoring and operation. This feature minimizes the need for manpower and reduces the risk of human error.

2. Precision Control The ability to control the position of the valve accurately is essential in many applications. Motorized gate valves provide precise flow regulation, ensuring optimal performance and system efficiency.

3. Safety In environments where hazardous materials are used, remote operation of motorized valves enhances safety. Operators can control the flow without being physically present near potential hazards.

4. Reduced Wear and Tear Manual valves are often subject to harsh operating conditions due to frequent adjustments. Motorized gate valves, with their steady actuation, experience less wear and tear, leading to longer service life and reduced maintenance costs.

5. Data Integration Motorized gate valves can be equipped with sensors and smart technologies that allow for real-time data acquisition and analysis. This integration aids in predictive maintenance and operational efficiency.

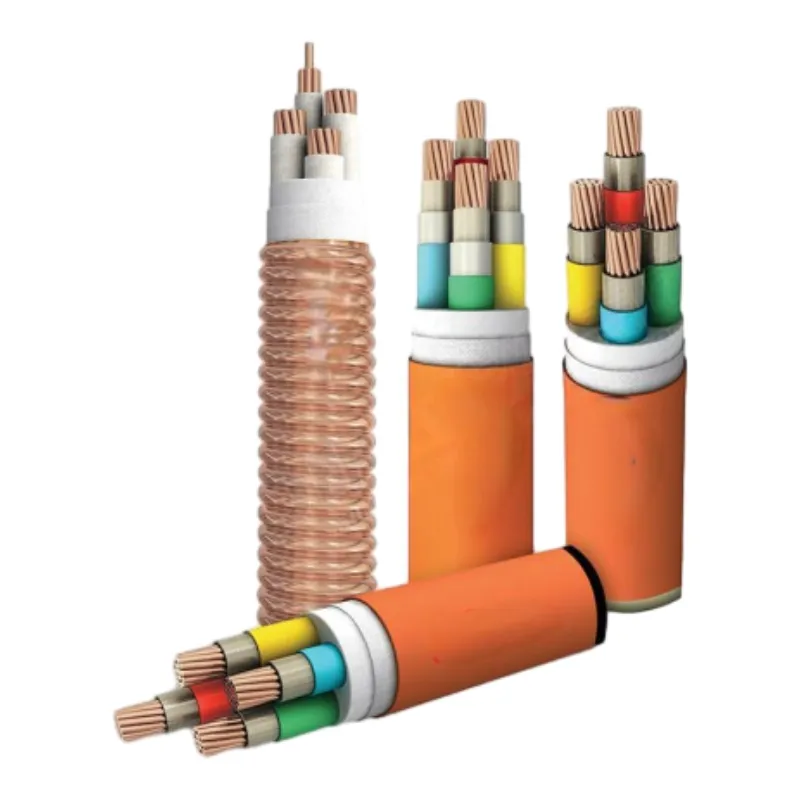

motorized gate valve

Applications

Motorized gate valves are versatile and find applications across numerous industries, including

- Water and Wastewater Treatment These valves play a crucial role in controlling the flow of water and chemicals in treatment processes

.- Oil and Gas In the extraction and transportation of oil and gas, motorized gate valves are used to manage flow in pipelines and storage facilities.

- Chemical Processing The precision control offered by motorized gate valves is vital in maintaining the integrity and safety of chemical processes.

- Power Generation In power plants, these valves are essential for regulating the flow of coolant and steam.

- HVAC Systems Motorized gate valves are also employed in heating, ventilation, and air-conditioning systems to control airflow and maintain temperature settings.

Maintenance

Maintaining motorized gate valves is crucial for ensuring their longevity and performance. Regular inspection of the actuator, motor, and valve seals is necessary to identify any signs of wear or damage. Lubrication should be performed according to the manufacturer's guidelines to reduce friction and prevent failure. Additionally, testing the control system and ensuring proper functionality are important maintenance practices.

Conclusion

Motorized gate valves represent a significant advancement in fluid control technology. Their automated operation, precision, and safety features make them indispensable in many industrial applications. As industries continue to embrace automation and smart technologies, the role of motorized gate valves will only grow, enhancing operational efficiency and safety across numerous sectors. By understanding their principles, benefits, applications, and maintenance requirements, engineers and operators can leverage these vital components to optimize their systems and processes.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025