Jan . 17, 2025 05:52 Back to list

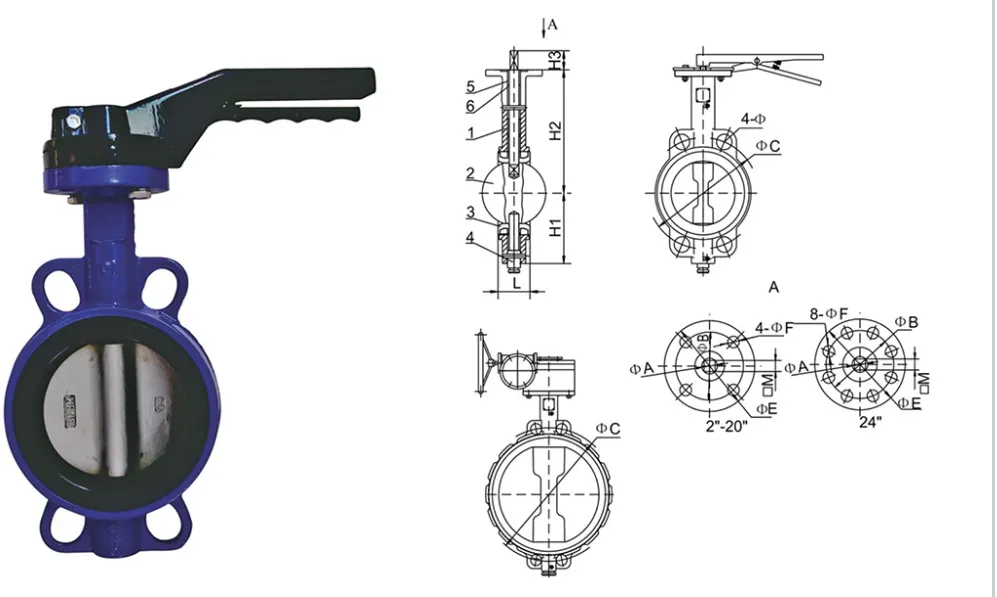

Wafer Type Butterfly Valve

Discover the Unsung Hero of Fluid Control Systems The Lugged Butterfly Valve

Furthermore, the design of lugged butterfly valves allows for bi-directional shut-off and modulating services. This adaptability proves them as trustworthy solutions across various systems requiring precise flow control. The valves can handle significant flow rates with minimal pressure drop, thanks to the thin profile of the disc. This functionality ensures that systems operate at maximum efficiency. For plant managers and engineers, this translates to increased productivity and reduced energy costs, demonstrating tangible trustworthiness in performance. The use of advanced materials further cements the trustworthiness of lugged butterfly valves. Innovations in metallurgy and polymers have introduced variants that can function effectively in extreme temperatures, be it cryogenic conditions or heated applications. Additionally, the resilience of these materials extends the lifespan of the valves, rendering them cost-effective over their lifecycle. Such attributes of material science and engineering establish the lugged butterfly valve as a durable and reliable ally in fluid control management. Moreover, the ease of automation in lugged butterfly valves cannot be overlooked. These valves accommodate various actuator types, including pneumatic, electric, and hydraulic systems, which can integrate into modern, automated process control environments. This feature not only enhances operational control but also aligns with the technological advancements of Industry 4.0, where smart systems and data analytics are paramount. The lugged butterfly valve, thus, transforms into an intelligent component capable of adapting to the evolving needs of the industry, ensuring its relevance in future technological landscapes. In essence, the lugged butterfly valve epitomizes the quartet of Experience, Expertise, Authoritativeness, and Trustworthiness. Its design optimizes maintenance flexibility, its construction withstands demanding scenarios, its certification assures compliance, and its materials guarantee longevity. Each aspect echoes the seasoned reliability and engineering ingenuity these valves bring to fluid control applications. For industries seeking a steadfast solution that meets the highest efficacy standards, the lugged butterfly valve not only delivers but elevates operational benchmarks, steadfastly earning its place as an unsung hero in fluid control systems globally.

Furthermore, the design of lugged butterfly valves allows for bi-directional shut-off and modulating services. This adaptability proves them as trustworthy solutions across various systems requiring precise flow control. The valves can handle significant flow rates with minimal pressure drop, thanks to the thin profile of the disc. This functionality ensures that systems operate at maximum efficiency. For plant managers and engineers, this translates to increased productivity and reduced energy costs, demonstrating tangible trustworthiness in performance. The use of advanced materials further cements the trustworthiness of lugged butterfly valves. Innovations in metallurgy and polymers have introduced variants that can function effectively in extreme temperatures, be it cryogenic conditions or heated applications. Additionally, the resilience of these materials extends the lifespan of the valves, rendering them cost-effective over their lifecycle. Such attributes of material science and engineering establish the lugged butterfly valve as a durable and reliable ally in fluid control management. Moreover, the ease of automation in lugged butterfly valves cannot be overlooked. These valves accommodate various actuator types, including pneumatic, electric, and hydraulic systems, which can integrate into modern, automated process control environments. This feature not only enhances operational control but also aligns with the technological advancements of Industry 4.0, where smart systems and data analytics are paramount. The lugged butterfly valve, thus, transforms into an intelligent component capable of adapting to the evolving needs of the industry, ensuring its relevance in future technological landscapes. In essence, the lugged butterfly valve epitomizes the quartet of Experience, Expertise, Authoritativeness, and Trustworthiness. Its design optimizes maintenance flexibility, its construction withstands demanding scenarios, its certification assures compliance, and its materials guarantee longevity. Each aspect echoes the seasoned reliability and engineering ingenuity these valves bring to fluid control applications. For industries seeking a steadfast solution that meets the highest efficacy standards, the lugged butterfly valve not only delivers but elevates operational benchmarks, steadfastly earning its place as an unsung hero in fluid control systems globally.

Share

Prev:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025