Nov . 06, 2024 23:37 Back to list

lined butterfly valve

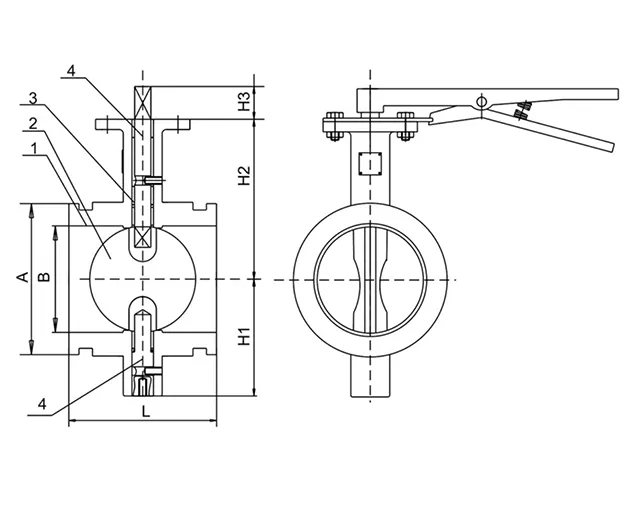

Understanding the Lined Butterfly Valve A Comprehensive Overview

The lined butterfly valve is an essential component in various industrial applications, particularly in systems that manage fluids and gases. Its unique design and functionality make it ideal for controlling flow while minimizing pressure drop, and its lining material provides excellent resistance to corrosion and wear.

Design and Operation

At the core of the lined butterfly valve is a disc that pivots around a central axis. This disc regulates the flow of fluid passing through the valve body. When the valve is in the open position, the disc is turned parallel to the flow, allowing for an unobstructed passage. Conversely, when the valve is closed, the disc rotates 90 degrees to block the flow. This simple yet effective design allows for quick operation, making it a popular choice in many industries.

The lining material is often made from elastomers or plastics, such as EPDM, PTFE, or polyurethane. These materials offer exceptional resistance to harsh chemicals, temperature extremes, and mechanical wear. This makes lined butterfly valves particularly suitable for applications in the chemical processing, water treatment, and food and beverage industries, where contamination and corrosion are significant concerns.

Advantages

One of the main advantages of lined butterfly valves is their lightweight design, which allows for easier installation and maintenance compared to traditional valves. Additionally, the reduced number of moving parts contributes to lower maintenance costs and increased reliability. The smooth operation of the rotary motion results in less wear and tear compared to linear gate or globe valves.

Another notable benefit is the low-pressure drop across the valve when it is in the open position. This characteristic is vital in systems where maintaining pressure is important for efficient operation. The streamlined flow path reduces turbulence, which further enhances the overall system efficiency.

lined butterfly valve

Applications

Lined butterfly valves are widely used in various sectors, including

1. Chemical Processing The valves can handle aggressive fluids, making them ideal for chemical reactors and storage tanks. 2. Water Treatment They are commonly used in potable and wastewater treatment applications due to their resistance to corrosive environments.

3. Food and Beverage The hygienic design and the ease of cleaning make these valves suitable for food processing lines.

4. Pharmaceutical Their ability to handle sterile applications without contaminating the process is crucial in pharmaceutical manufacturing.

Conclusion

The lined butterfly valve is a versatile and efficient solution for flow control in various industrial applications. Its design provides numerous advantages, including lightweight construction, minimal maintenance, low-pressure drop, and resistance to corrosion. As industries continue to evolve, the importance of such innovative solutions becomes increasingly evident, ensuring the longevity and reliability of processes across different sectors. Whether in chemical, water treatment, or food processing applications, lined butterfly valves play a pivotal role in enhancing operational efficiency and safety.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025