Dec . 13, 2024 19:50 Back to list

lever operated butterfly valve

Lever Operated Butterfly Valve An Overview

Butterfly valves are essential components in various industrial applications, functioning primarily to regulate and control the flow of fluids. The lever-operated butterfly valve stands out due to its simplicity and effectiveness, featuring a disc that pivots about a central axis and a lever that allows for manual operation. This article explores the design, operation, applications, and advantages of lever-operated butterfly valves.

Design and Operation

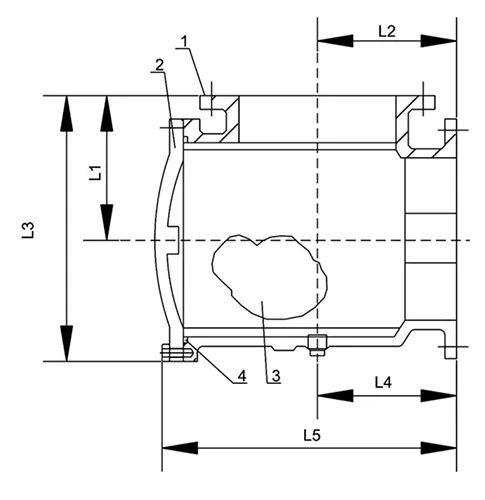

A lever-operated butterfly valve consists of several key components the body, disc, stem, and lever. The body is typically made from durable materials such as stainless steel, ductile iron, or PVC, capable of withstanding high pressures and corrosive environments. The disc, usually made of metal or plastic, is mounted on a shaft that connects to the lever.

The operation is straightforward. The lever is attached to the stem of the valve, allowing the operator to open or close the valve by rotating the lever. When the lever is turned, the disc rotates, either parallel to or perpendicular to the flow direction. A 90-degree rotation usually allows for a full open or closed position, enabling rapid control of the flow.

Applications

Lever-operated butterfly valves are widely used in various industries, including water treatment, wastewater management, chemical processing, and HVAC systems. Their versatility makes them suitable for applications that involve the flow of gases, liquids, and even slurries.

1. Water Treatment In water treatment plants, these valves regulate the flow of water through pipelines and filtration systems. Their quick operation allows for efficient control during routine maintenance and emergency situations.

2. Chemical Processing The ability to handle corrosive and hazardous materials makes lever-operated butterfly valves an excellent choice for chemical processing plants. Their design minimizes leaks and ensures the safety of operations.

3. HVAC Systems Lever-operated butterfly valves are commonly found in heating, ventilation, and air conditioning systems to control airflow. Their compact design aids in installation in tight spaces.

lever operated butterfly valve

4. Food and Beverage Industry In the food and beverage industry, these valves are preferred for their hygienic design and ease of cleaning. They help maintain the integrity of products by preventing contamination.

Advantages

Lever-operated butterfly valves provide several significant advantages

1. Ease of Operation The lever mechanism allows for simple manual operation, making it user-friendly, even in environments with limited automation. Operators can quickly respond to changes in flow requirements.

2. Compact Design These valves occupy less space compared to other valve types, making them ideal for installations where space is constrained. Their lightweight nature also results in lower installation costs.

3. Cost-Effective Lever-operated butterfly valves are often more economical than other valve types, such as gate or globe valves. Their simple design translates to lower manufacturing costs and reduced maintenance expenses.

4. Versatile Their ability to handle a variety of fluids and gases makes them applicable in numerous industries, contributing to their widespread acceptance.

5. Low Pressure Drop Butterfly valves generally have low pressure drops when fully open, which helps maintain efficient flow rates in piping systems.

Conclusion

The lever-operated butterfly valve is an invaluable tool in many industries, providing efficient flow control, ease of use, and versatility. Their design allows for quick operation, making them suitable for various applications where speed and reliability are essential. As industries continue to evolve and seek more efficient methods to manage fluids, lever-operated butterfly valves will likely remain a preferred choice for operators worldwide. Their advantages of compactness, cost-effectiveness, and user-friendly operation ensure their place in the future of fluid control technology. Whether in a water treatment facility, a chemical processing plant, or an HVAC system, these valves play a critical role in ensuring fluid management is performed effectively and safely.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025