Nov . 27, 2024 20:28 Back to list

Innovative Solutions for Industrial Globe Valve Applications and Performance Enhancement

Understanding Industrial Globe Valves A Key Component in Fluid Control

Industrial globe valves are essential devices employed in a variety of fluid control applications across multiple industries, including oil and gas, water treatment, power generation, and chemical processing. Known for their distinctive shape and versatile functionality, globe valves play a vital role in managing the flow of fluids, whether it be for regulation, isolation, or as part of a larger control system.

Design and Function

The globe valve is characterized by its spherical body shape, which gives it the name globe. This type of valve features a movable disk or plug that sits on a stationary ring seat, allowing for precise control of fluid flow. When the valve is fully opened, the flow path is unobstructed, while turning the valve handle closes it gradually, reducing the flow to an exact desired rate. This excellent throttling capability makes globe valves particularly useful for applications that require a controlled flow, unlike gate valves that are primarily suited for on-off service.

Advantages of Globe Valves

1. Flow Control Globe valves are renowned for their superior ability to regulate flow. Their design provides better throttling capabilities compared to other valve types, enabling fine-tuning of fluid dynamics.

2. Versatility These valves can handle a wide range of fluids, including liquids, gases, and steam, making them versatile components in industrial settings. They can be used in various configurations, such as straight-through or angle patterns, depending on the installation requirements.

3. Durability Built to withstand high temperatures and pressures, industrial globe valves are constructed from a variety of materials, including stainless steel, carbon steel, and various alloys. This durability ensures long-term service in challenging environments.

4. Reliability Due to their robust design and materials, globe valves provide reliable performance and leak-tight closure. This aspect is crucial in preventing spills and ensuring safety in industrial operations.

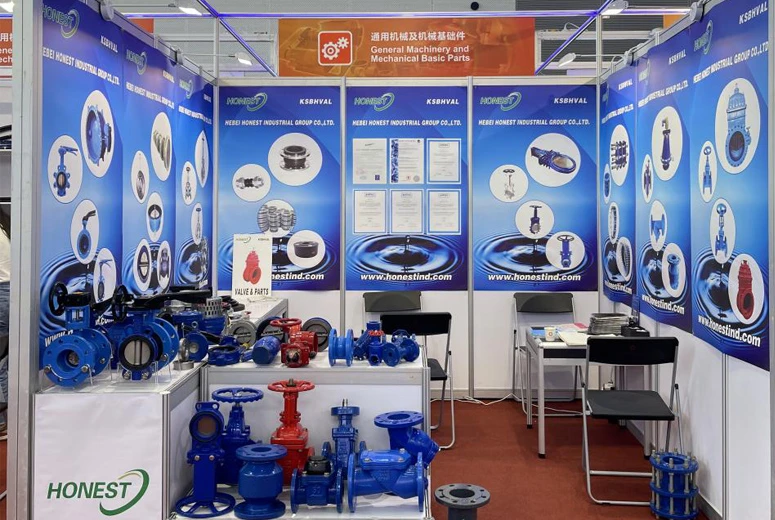

industrial globe valve

Applications

The applications of globe valves are vast, spanning numerous industrial fields. In the oil and gas industry, they regulate the flow of crude oil and natural gas, ensuring safe and efficient transport through pipelines. In power plants, they manage steam flow to turbines, directly impacting energy output and operational efficiency.

In water treatment facilities, globe valves are employed to control the flow of treated water, chemicals, and sludge, playing a critical role in maintaining the quality of water distributed to communities. Similarly, in chemical processing, globe valves are essential for maintaining the precise flow of reactive substances, ensuring safe and efficient production processes.

Maintenance and Considerations

Proper maintenance is crucial for the longevity and functionality of globe valves. Regular inspections should be conducted to check for leaks, corrosion, and mechanical wear. Additionally, operators should ensure that the valves are exercised periodically to prevent sticking and maintain their operational integrity.

When selecting a globe valve, factors such as the type of fluid, temperature, pressure, and specific application must be considered to ensure compatibility and optimal performance. Consulting with valve manufacturers or specialists can provide valuable insights into the best choices for specific needs.

Conclusion

Industrial globe valves are indispensable tools for fluid control in various industries. Their unique design enables precise regulation of flow, making them suitable for numerous applications. With advantages such as durability, reliability, and versatility, globe valves contribute significantly to the efficiency and safety of industrial operations. Understanding their function and proper maintenance is essential for maximizing their performance and ensuring a seamless operational process. As industries evolve, the importance of globe valves in fluid management will undoubtedly remain a key focus for engineers and operators alike.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025