Sep . 05, 2024 13:22 Back to list

industrial water valve

Understanding Industrial Water Valves Key Components and Their Importance

Industrial water valves play a critical role in the management and control of water systems within various industrial settings. These valves are essential for regulating the flow of water in pipelines, ensuring operational efficiency, safety, and sustainability in environments ranging from manufacturing plants to wastewater treatment facilities. By understanding the types, functions, and maintenance of industrial water valves, businesses can significantly enhance their water management strategy.

Types of Industrial Water Valves

There are several types of water valves utilized in industrial applications, each designed for specific functions

1. Gate Valves These valves are primarily used for on/off control of flow. They provide minimal pressure loss and are suitable for applications where the valve will either be fully open or fully closed.

2. Globe Valves Known for their ability to regulate flow, globe valves are ideal for applications that require throttling. Their design allows for greater flow control and is preferred in systems where precise adjustments are necessary.

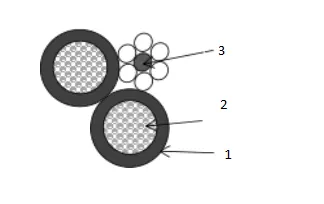

3. Ball Valves Featuring a spherical closure element, ball valves provide excellent sealing and relatively low pressure drops. They are versatile and can be used for both on/off and throttling services.

4. Check Valves These are one-way valves that prevent backflow in piping systems. They are crucial in preventing water contamination and maintaining system pressure.

5. Butterfly Valves Utilized for quick shut-off and flow regulation, butterfly valves are lightweight and offer quick operation, making them suitable for large-scale piping systems.

Functions of Industrial Water Valves

industrial water valve

The primary function of industrial water valves is to control the flow of water within a system. By adjusting the valve position, operators can regulate water pressure, manage flow rates, and divert water to different sections of a facility. This control is essential for processes such as cooling, heating, and chemical processing.

In wastewater treatment, for instance, valves help manage the flow of water through various treatment stages. Ensuring optimal flow rates is crucial for effective filtration and treatment, which ultimately affects the quality of discharged water.

Importance of Maintenance

Regular maintenance of industrial water valves is vital to ensure their reliability and longevity. Over time, wear and tear can lead to leaks, corrosion, or failure, which can disrupt operations and lead to costly downtime. A well-maintained valve system minimizes the risk of unexpected failures and helps maintain safety standards.

Key maintenance practices include

- Routine Inspections Regularly checking valves for signs of wear, leaks, and corrosion can help identify potential issues before they escalate.

- Cleaning and Lubrication Keeping valves clean and properly lubricated is essential for smooth operation. Contaminants can cause blockages or reduce the effectiveness of valve seals.

- Testing Conducting functional tests on valves ensures they perform as intended. This includes testing for pressure drops and response times.

Conclusion

Industrial water valves are an integral part of water management systems across various industries. Understanding their types, functions, and maintenance needs is crucial for any business that relies on water for its operations. By investing in the right valves and maintaining them diligently, companies can enhance efficiency, ensure operational reliability, and contribute to environmental sustainability. In a world increasingly focused on resource conservation, well-managed water systems represent a vital step toward responsible industrial practices.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025