Jan . 13, 2025 17:45 Back to list

high performance wafer butterfly valve

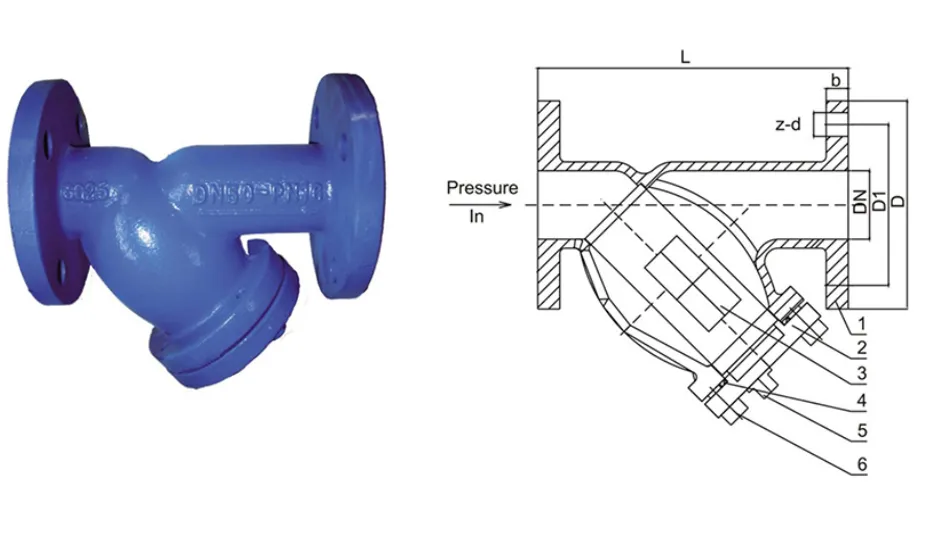

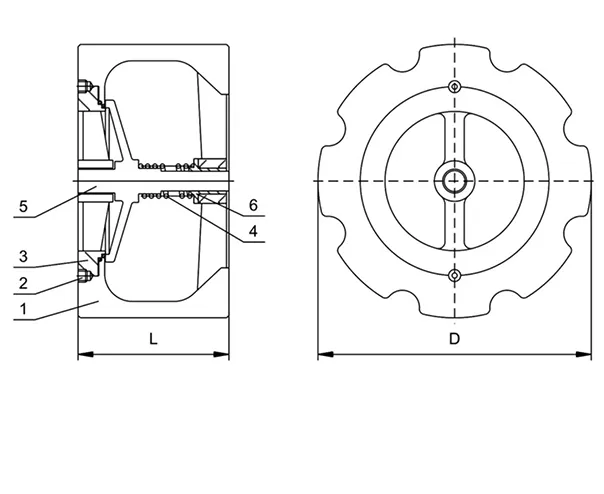

In the realm of fluid control systems, the wafer type butterfly valve is increasingly recognized for its innovative design and superior functionality. These valves play a pivotal role in ensuring efficient flow control in various industries, such as water treatment, chemical processing, and HVAC systems. What sets the DI wafer type butterfly valve apart is its robust construction and ease of use.

The expertly engineered sealing mechanism of the DI wafer type butterfly valve further bolsters its reputation for trustworthiness. The elastomeric liner ensures excellent sealing capabilities, even in challenging operating conditions. Importantly, this liner is usually replaceable, which extends the valve’s lifecycle and reduces long-term maintenance costs. Such features enhance the valve's attractiveness among engineers and procurement specialists who seek solutions that offer economic efficiency without compromising on quality or performance. Additionally, the user-friendly nature of the DI wafer type butterfly valve cannot be overstated. Operating these valves requires minimal torque, thanks to the advanced design of the valve’s bearings and bushings. This reduces the need for large actuators, making the system more energy-efficient. The valve's overall design reflects the input from industry experts and extensive field research, ensuring it meets contemporary demands for operational precision and ease of use. The DI wafer type butterfly valve is trusted by industry professionals due to its adherence to industry standards and certifications, which guarantee its performance under specific conditions. Leading manufacturers conduct rigorous testing, ensuring each valve meets stringent criteria before it reaches the end user. This dedication to quality underscores the valve's authoritativeness and reliability in critical applications. In conclusion, the DI wafer type butterfly valve stands out in the marketplace for its robust construction, ease of use, and reliable performance. It reflects a harmonious marriage of expert engineering and practical design, meeting the diverse and demanding needs of modern fluid control systems. Whether in water treatment facilities or chemical processing plants, this valve is an exemplary choice for professionals who prioritize efficiency, longevity, and cost-effectiveness in their operations.

The expertly engineered sealing mechanism of the DI wafer type butterfly valve further bolsters its reputation for trustworthiness. The elastomeric liner ensures excellent sealing capabilities, even in challenging operating conditions. Importantly, this liner is usually replaceable, which extends the valve’s lifecycle and reduces long-term maintenance costs. Such features enhance the valve's attractiveness among engineers and procurement specialists who seek solutions that offer economic efficiency without compromising on quality or performance. Additionally, the user-friendly nature of the DI wafer type butterfly valve cannot be overstated. Operating these valves requires minimal torque, thanks to the advanced design of the valve’s bearings and bushings. This reduces the need for large actuators, making the system more energy-efficient. The valve's overall design reflects the input from industry experts and extensive field research, ensuring it meets contemporary demands for operational precision and ease of use. The DI wafer type butterfly valve is trusted by industry professionals due to its adherence to industry standards and certifications, which guarantee its performance under specific conditions. Leading manufacturers conduct rigorous testing, ensuring each valve meets stringent criteria before it reaches the end user. This dedication to quality underscores the valve's authoritativeness and reliability in critical applications. In conclusion, the DI wafer type butterfly valve stands out in the marketplace for its robust construction, ease of use, and reliable performance. It reflects a harmonious marriage of expert engineering and practical design, meeting the diverse and demanding needs of modern fluid control systems. Whether in water treatment facilities or chemical processing plants, this valve is an exemplary choice for professionals who prioritize efficiency, longevity, and cost-effectiveness in their operations.

Share

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025