Feb . 10, 2025 22:27 Back to list

High Performance Butterfly Valve

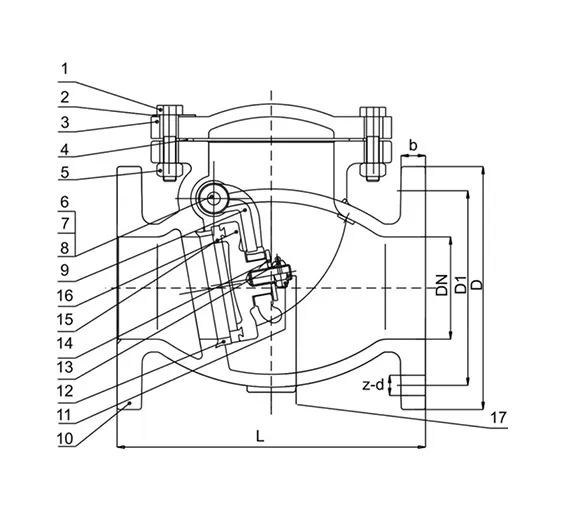

High performance butterfly valves have become essential components in many industrial settings, delivering superior control for both on-off and modulating services. Their unique design, characterized by a disk rotating on a diametrical axis inside a pipe, provides several advantages over traditional valve types, making them a preferred choice for varied applications.

In terms of real-world experience, high performance butterfly valves have been successfully integrated across various sectors. For instance, in water treatment facilities, these valves play a crucial role in managing the flow of different liquids, ensuring clean and safe water distribution. Their adaptability allows them to handle everything from clean to corrosive or abrasive fluids, highlighting their versatility. In the oil and gas industry, these valves are commonly used to manage the flow of steam, gas, or other petroleum products. The economic and environmental stakes are high in such sectors, and reliable flow control is essential to maintaining productivity and reducing environmental impact. Companies have reported substantial improvements in efficiency and reduced downtime post implementation, underscoring the valves’ pivotal role in process optimization. Finally, for any facility considering the integration of high performance butterfly valves, it is crucial to partner with experienced technicians and engineers. These professionals bring the technical knowledge necessary to ensure proper installation and calibration, maximizing the valves' performance. Moreover, having access to a knowledgeable support team can ease concerns about operational challenges, contributing to a smooth, hassle-free implementation. By understanding the nuances of high performance butterfly valves—from material considerations to real-world applications—industries can better harness their potential to achieve superior control and efficiency in production processes.

In terms of real-world experience, high performance butterfly valves have been successfully integrated across various sectors. For instance, in water treatment facilities, these valves play a crucial role in managing the flow of different liquids, ensuring clean and safe water distribution. Their adaptability allows them to handle everything from clean to corrosive or abrasive fluids, highlighting their versatility. In the oil and gas industry, these valves are commonly used to manage the flow of steam, gas, or other petroleum products. The economic and environmental stakes are high in such sectors, and reliable flow control is essential to maintaining productivity and reducing environmental impact. Companies have reported substantial improvements in efficiency and reduced downtime post implementation, underscoring the valves’ pivotal role in process optimization. Finally, for any facility considering the integration of high performance butterfly valves, it is crucial to partner with experienced technicians and engineers. These professionals bring the technical knowledge necessary to ensure proper installation and calibration, maximizing the valves' performance. Moreover, having access to a knowledgeable support team can ease concerns about operational challenges, contributing to a smooth, hassle-free implementation. By understanding the nuances of high performance butterfly valves—from material considerations to real-world applications—industries can better harness their potential to achieve superior control and efficiency in production processes.

Share

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025