Dec . 19, 2024 16:39 Back to list

high performance butterfly valve

The High-Performance Butterfly Valve A Game Changer in Industrial Applications

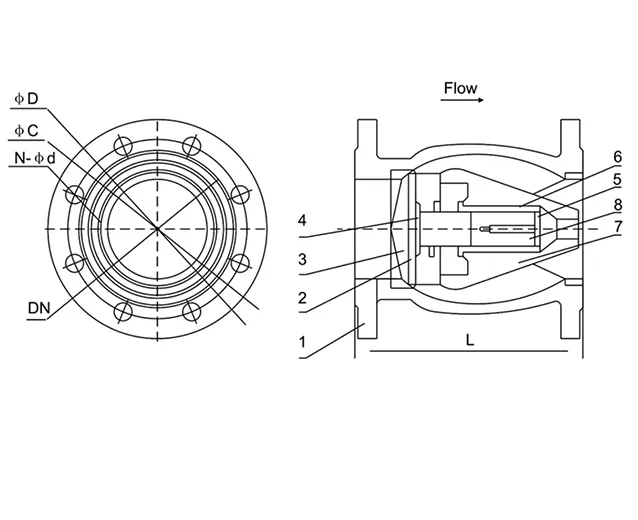

Butterfly valves are essential components in various industrial applications, providing an efficient and reliable method of controlling the flow of fluids. Among the various types of butterfly valves, high-performance butterfly valves stand out for their advanced design principles and superior capabilities. These valves are engineered to offer high efficiency, durability, and flexibility, making them a preferred choice in several demanding environments.

One of the most significant advantages of high-performance butterfly valves is their enhanced flow control. Unlike traditional butterfly valves, high-performance variants are designed with a more sophisticated sealing mechanism and streamlined shape. This allows them to achieve better flow characteristics, minimizing turbulence and pressure drop in the pipeline system. As a result, industries can expect better energy efficiency, lower operational costs, and improved overall performance.

The High-Performance Butterfly Valve A Game Changer in Industrial Applications

Maintenance and operational ease are also key benefits associated with high-performance butterfly valves. Many designs incorporate user-friendly features, such as accessible components for servicing and modular designs that facilitate quick replacements. This aspect is particularly important in industries where downtime can lead to significant financial losses. A high-performance butterfly valve can often be repaired or replaced swiftly without extensive system interruptions, allowing operations to continue smoothly.

high performance butterfly valve

Furthermore, high-performance butterfly valves are known for their versatility. They can be configured for various applications, whether it requires throttling, on/off control, or even isolation. Their adaptability makes them suitable for a wide range of industries, including water treatment, HVAC systems, and pharmaceutical manufacturing, among others. Depending on the specific application requirements, these valves can be fitted with various actuators, such as electric, pneumatic, or hydraulic systems, to enhance automation and efficiency.

The design and engineering of high-performance butterfly valves also prioritize safety. Many modern versions integrate advanced features like position indicators, fail-safe mechanisms, and advanced control systems to prevent accidental operation and ensure safe handling of potentially hazardous materials. These safety features not only protect personnel but also contribute to the overall integrity of the system, reducing the likelihood of leaks or catastrophic failures.

In addition to their functional advantages, high-performance butterfly valves are becoming increasingly important in the context of sustainability. As industries worldwide strive to reduce their environmental footprints, the efficiency and reliability of high-performance valves contribute to minimizing waste and optimizing resource use. By ensuring better control over fluid dynamics, these valves help industries meet regulatory requirements and environmental standards.

In conclusion, high-performance butterfly valves represent a significant advancement in valve technology, providing unparalleled flow control, durability, and versatility in various industrial applications. Their design innovations not only enhance operational efficiency but also contribute to safety and sustainability in fluid handling systems. As industries continue to evolve, the demand for such advanced valve solutions is likely to grow, making high-performance butterfly valves a crucial component of modern engineering practices. For businesses looking to improve their operational capabilities and reduce costs, investing in high-performance butterfly valves is a strategic choice that can drive long-term success.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025