Aug . 10, 2025 03:20 Back to list

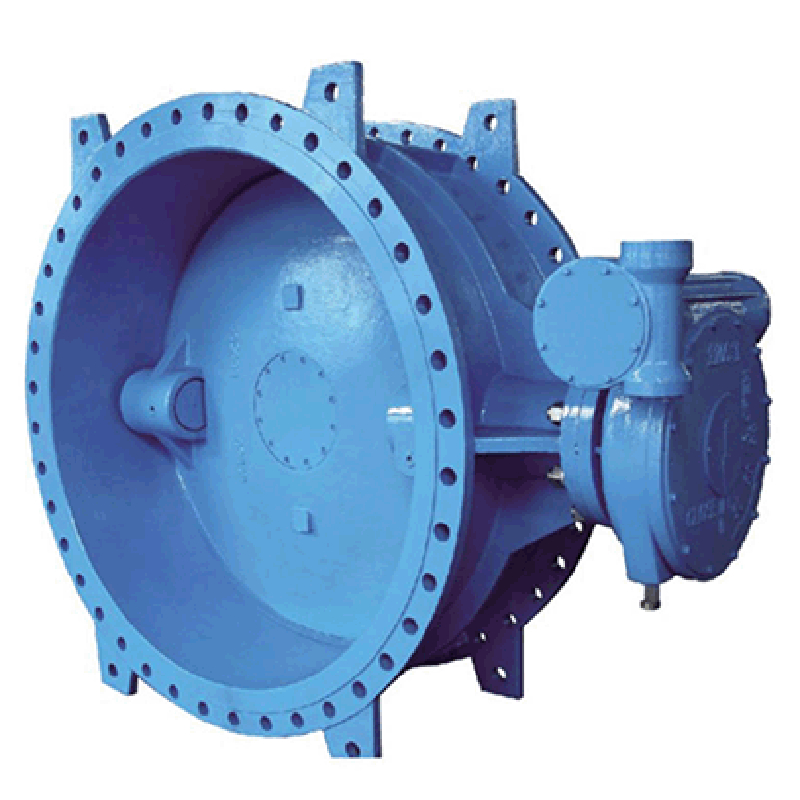

High-Performance Double Eccentric Flange Butterfly Valve

Unlocking Efficiency: A Deep Dive into Double Eccentric Flange Butterfly Valve Technology

In the intricate world of fluid control, precision, durability, and operational efficiency are paramount, particularly within demanding industrial sectors such as petrochemical, metallurgy, water treatment, and power generation. Among the various valve types critical for managing liquid and gas flows, the double eccentric flange butterfly valve stands out as a superior solution, engineered to address the limitations inherent in traditional concentric designs. This advanced valve technology, often referred to as a high-performance butterfly valve, distinguishes itself through its unique disc design and shaft offset, which collectively minimize contact between the disc and the seat during the opening and closing cycles. This reduction in friction significantly extends the valve's service life, reduces wear and tear on critical components, and lowers operational torque requirements, leading to substantial energy savings and reduced maintenance overheads for industrial operators. The design inherently improves sealing capabilities, especially under high-pressure and high-temperature conditions, making it a preferred choice over standard butterfly valves in applications where bubble-tight shutoff is indispensable. Our commitment to innovation and engineering excellence ensures that our double eccentric flange butterfly valve products not only meet but exceed rigorous industry standards, providing reliable, long-term performance even in the most corrosive or abrasive environments. This detailed exploration will delve into the profound technical advantages, intricate manufacturing processes, diverse application scenarios, and comprehensive support systems that underpin the value proposition of these indispensable valves, underscoring their critical role in optimizing industrial processes globally. We aim to provide B2B decision-makers and technical personnel with a holistic understanding of why investing in high-quality double eccentric flange butterfly valve solutions is a strategic imperative for enhancing system integrity and operational sustainability. The careful selection of materials, adherence to strict manufacturing tolerances, and the implementation of advanced sealing technologies are central to achieving the superior performance characteristics that differentiate these valves from their counterparts. Furthermore, the rising demand for energy-efficient solutions and more stringent environmental regulations are driving industries towards adopting advanced valve technologies that can withstand extreme conditions while ensuring minimal fluid leakage and reduced energy consumption. The inherent design of the double eccentric valve mitigates the common issues of disc impingement and seat wear, which are prevalent in simpler butterfly valve designs, thereby offering a robust and cost-effective solution for complex fluid handling systems. This design philosophy directly translates into enhanced reliability and reduced total cost of ownership over the valve’s operational lifespan, making it an economically astute choice for long-term industrial deployments. Our focus extends beyond merely providing a product; we offer integrated solutions that encompass expert consultation, customized design, and comprehensive after-sales support, ensuring that our clients achieve optimal performance and maximum return on their investment in this critical infrastructure component. The adaptability of these valves across a broad spectrum of media, from clean water to abrasive slurries, further solidifies their position as a cornerstone technology in modern industrial fluid management.

Mastering the Craft: The Manufacturing Process of Double Eccentric Flange Butterfly Valves

The production of a high-performance double eccentric flange butterfly valve is an elaborate process that demands stringent quality control at every stage, from raw material procurement to final assembly and testing. Our manufacturing methodology integrates cutting-edge technology with meticulous craftsmanship to ensure each valve meets the highest standards of reliability and longevity. The process typically commences with the careful selection of premium materials, which are crucial for the valve's performance in diverse operating environments. For the valve body, common materials include ductile iron (ASTM A536), carbon steel (ASTM A216 WCB), stainless steel (ASTM A351 CF8M/CF3M), and various alloys, chosen based on the intended application's pressure, temperature, and media corrosivity requirements. The disc, which is the primary flow control element, often utilizes similar high-grade materials, sometimes with specialized coatings like PFA or PTFE for enhanced chemical resistance. The shaft, critical for precise disc rotation, is typically made from robust materials such as stainless steel 410, 304, or 316, selected for their strength and corrosion resistance. Sealing components, which define the valve's leak-tightness, are manufactured from resilient elastomers like EPDM or NBR for general industrial use, or more advanced materials such as Viton (FKM) or PTFE for higher temperatures and aggressive chemicals. The manufacturing journey begins with either casting or forging, depending on the valve's size and pressure rating. Precision casting processes, often involving sand casting or investment casting, are employed for complex body shapes, ensuring uniform wall thickness and structural integrity. Forging, a process that improves material grain structure and enhances mechanical properties, is used for components requiring superior strength and fatigue resistance. Post-casting or forging, intensive CNC machining takes center stage. This phase is critical for achieving the precise dimensional tolerances required for the double eccentric design. The intricate machining of the valve body, disc, and shaft ensures that the two offsets (one between the shaft and disc center, the other between the shaft and pipeline center) are perfectly calibrated. This precision is what allows the disc to lift off the seat with minimal friction upon opening and achieve a tight seal upon closing, without scraping the seat. The sophisticated CNC machines enable repeatable accuracy, which is paramount for the valve's long-term performance and sealing integrity. Following machining, components undergo rigorous cleaning and surface treatment processes, which may include passivation for stainless steel or protective coatings to enhance corrosion resistance and reduce friction. Assembly is performed in controlled environments, with skilled technicians meticulously fitting each component, paying particular attention to the seat-disc alignment and proper torquing of fasteners. Integral to our process are comprehensive inspection standards. Every double eccentric flange butterfly valve undergoes a series of stringent quality checks, adhering to international standards such as ISO 9001 for quality management systems, API 609 for design, manufacture, and testing of butterfly valves, and ANSI/ASME B16.34 for valve dimensions and pressure ratings. Hydrostatic shell and seat tests are conducted to verify pressure integrity and bubble-tight shutoff capabilities. Fugitive emissions testing, often to ISO 15848-1 standards, is performed for applications where environmental protection and compliance with stringent regulations are critical. These meticulous testing protocols ensure that each valve leaving our facility is certified for its specified performance, offering an expected service life extending well beyond 20 years under typical operating conditions. This robust manufacturing and testing regime is what allows us to confidently provide solutions that deliver unparalleled reliability and efficiency in industries such as petrochemicals, where hazardous media demand zero leakage; in metallurgical plants, where abrasive slurries necessitate wear-resistant components; in municipal water and wastewater treatment, where long-term, maintenance-free operation is crucial; and in HVAC systems, where precise flow control contributes significantly to energy efficiency. The emphasis on advanced manufacturing techniques, coupled with rigorous quality assurance, guarantees that our double eccentric flange butterfly valve offerings contribute directly to energy conservation, enhanced safety, and superior process control, consistently outperforming conventional valve types in demanding industrial contexts.

Illustrative representation of double eccentric flange butterfly valve components and their assembly.

Technical Prowess: Parameters and Performance of Double Eccentric Flange Butterfly Valves

The performance superiority of the double eccentric flange butterfly valve stems from its meticulously engineered technical parameters and innovative design principles. Unlike concentric butterfly valves where the disc rotates on a central axis, the double eccentric design introduces two offsets: the first offset is between the shaft center and the disc center, and the second offset is between the shaft center and the pipe center. These deliberate eccentricities enable the disc to lift away from the seat almost immediately upon actuation, significantly reducing seating friction and wear, which are common issues in other valve types. This "camming action" ensures that the disc only makes full contact with the seat at the very final degrees of closure, providing a robust, repeatable, and bidirectional bubble-tight seal. This minimal contact during operation translates directly into lower operating torque requirements, allowing for smaller, more cost-effective actuators and reducing energy consumption over the valve's lifespan. Furthermore, the reduced friction extends the service life of both the seat and the disc, deferring costly maintenance and replacements. The design also facilitates higher Cv values (flow coefficients) for a given valve size compared to globe valves or some ball valves, indicating lower pressure drop and higher flow capacity, which leads to improved system efficiency. Key technical parameters for these valves include nominal diameter (DN/NPS), ranging typically from DN50 (2 inches) up to DN3000 (120 inches) or more for large infrastructure projects; nominal pressure (PN/Class), with common ratings including PN10, PN16, PN25, PN40, ANSI Class 150, 300, 600, accommodating a wide spectrum of industrial pressures; and applicable temperature ranges, which can vary from -40°C to +200°C depending on the body, disc, and seat materials selected. For instance, an EPDM seat can handle temperatures up to 120°C, while a Viton or PTFE seat can extend this range significantly. The body style is predominantly flanged, in accordance with standards like EN 1092-1 or ASME B16.5, ensuring easy integration into existing pipeline systems. Actuation methods are versatile, including manual (lever or gearbox), pneumatic, electric, or hydraulic actuators, providing flexibility in control and automation. The selection of materials is paramount; for instance, a valve intended for corrosive chemical service might feature a stainless steel 316L body with a PTFE-lined disc and seat, while a municipal water application might use a ductile iron body with an EPDM seat. Our engineering team leverages extensive experience and industry data to guide clients in selecting the optimal material combinations and specifications, ensuring the valve’s long-term compatibility and performance with the specific media and operating conditions. For example, in wastewater treatment, the resistance to abrasive particles and corrosive chemicals is a critical factor, making choices like epoxy-coated ductile iron bodies and wear-resistant stainless steel discs with EPDM seats common. The reliability of our double eccentric flange butterfly valves is validated through rigorous internal testing and adherence to global certification standards. Each valve is designed to minimize cavitation, particularly important in high-flow applications where pressure drops can cause vapor bubble formation and subsequent collapse, leading to erosion and noise. The streamlined flow path through the open disc reduces turbulence and pressure loss, further contributing to the valve's energy-saving attributes. These technical attributes collectively position the double eccentric flange butterfly valve as an economically viable and technically superior choice for critical flow isolation and control applications across a multitude of industries, consistently delivering lower total cost of ownership through extended service intervals and reduced operational energy expenditure compared to alternative valve types. Our detailed product specifications and performance curves, derived from extensive R&D and field data, provide our clients with the necessary information to make informed decisions for their most demanding projects.

| Parameter | Typical Range/Value | Description |

|---|---|---|

| Nominal Diameter (DN/NPS) | DN50 - DN3000 (2" - 120") | Range of available pipe sizes. |

| Nominal Pressure (PN/Class) | PN10/16/25/40, ANSI Class 150/300/600 | Pressure ratings for various applications. |

| Body Material | Ductile Iron (GGG40/50), Carbon Steel (WCB), Stainless Steel (CF8M/CF3M), Duplex | Material of the valve housing. |

| Disc Material | Ductile Iron (Ni-plated), Stainless Steel (CF8M/CF3M), Bronze, Aluminium Bronze | Material of the flow control element. |

| Shaft Material | SS410, SS304, SS316, SS431 | Material of the stem connecting to the actuator. |

| Seat Material | EPDM, NBR, Viton (FKM), PTFE, Metal-to-Metal | Material providing the seal against the disc. |

| Applicable Temperature | -40°C to +200°C (Material Dependent) | Temperature range the valve can withstand. |

| Leakage Class | Class VI (API 598 / ANSI B16.104) | Highest level of shut-off capability, bubble-tight. |

| Actuation | Manual (Lever/Gearbox), Pneumatic, Electric, Hydraulic | Method for operating the valve. |

Strategic Deployment: Application Scenarios and Key Advantages of Double Eccentric Flange Butterfly Valves

The robust design and superior performance characteristics of the double eccentric flange butterfly valve make it an indispensable component across a multitude of demanding industrial applications where reliable shut-off and precise flow control are critical. Its inherent advantages over other valve types, particularly in terms of extended service life, reduced maintenance, and superior sealing capabilities, translate into significant operational efficiencies and cost savings for end-users. In the petrochemical industry, where highly corrosive and high-temperature media are common, these valves are extensively used in refinery processes, chemical processing plants, and oil and gas transportation pipelines. Their ability to maintain a bubble-tight seal under varying pressures and temperatures, often up to ANSI Class 600, ensures safety and prevents fugitive emissions, which is paramount for environmental compliance and operational integrity. For example, in ethylene production, where extreme temperatures and aggressive chemicals are involved, the use of stainless steel or alloy steel double eccentric flange butterfly valves with specialized seat materials like PTFE ensures dependable isolation. Similarly, in the power generation sector, especially in thermal power plants and nuclear facilities, these valves are deployed in cooling water systems, boiler feed water lines, and ash handling systems. Their minimal pressure drop contributes to energy efficiency in large-volume fluid transfer, while their robust construction withstands the harsh conditions associated with steam and hot water applications. An example often cited is their application in condenser isolation, where the valve must provide tight shutoff for maintenance without disrupting plant operation. The metallurgical industry benefits greatly from their resilience to abrasive media and high temperatures. In steel mills, for instance, they are used in cooling water circuits for furnaces and continuous casting machines, as well as in dust collection and gas handling systems where large pipe sizes and reliable shutoff are required. The ductile iron or carbon steel variants with wear-resistant disc coatings are particularly suitable for handling slurries and abrasive particles. Moreover, in municipal water treatment and distribution networks, the double eccentric flange butterfly valve is a workhorse, providing reliable isolation for pumps, filters, and distribution mains. Its low torque operation is ideal for large diameter pipelines, and its ability to maintain a seal for decades, even with infrequent operation, makes it a cost-effective choice for buried installations or remotely operated stations. The epoxy coating on ductile iron bodies ensures excellent corrosion resistance against treated water and soil conditions. Furthermore, in HVAC systems for commercial buildings and industrial complexes, these valves are critical for managing chilled water and hot water loops, contributing to precise temperature control and energy management due to their low-pressure drop characteristics. The inherent anti-corrosion properties, achieved through meticulous material selection and advanced surface treatments, ensure the valve's longevity even when exposed to harsh chemicals or external environmental factors. For instance, in seawater desalination plants, the use of duplex stainless steel or super duplex stainless steel double eccentric flange butterfly valves is essential to resist the highly corrosive effects of concentrated brine. The primary technical advantage is the significant reduction in seat wear, leading to a much longer service life compared to traditional butterfly valves or even triple eccentric designs that are more complex and costly for many applications. This is directly attributable to the double offset design, which causes the disc to 'lift off' the seat immediately upon opening, preventing the rubbing action that causes premature wear. This also results in lower operating torque, which allows for the use of smaller, less expensive actuators, further reducing the overall system cost and energy consumption. The bidirectional sealing capability means the valve can provide a tight shutoff regardless of flow direction, enhancing operational flexibility and safety. These combined advantages make the double eccentric flange butterfly valve an economically superior choice, offering a lower total cost of ownership over its lifespan through reduced maintenance, improved energy efficiency, and extended operational reliability in diverse and demanding industrial environments.

A typical application of a double eccentric flange butterfly valve in an industrial pipeline.

Choosing Wisely: Manufacturer Comparison and Custom Solutions for Double Eccentric Flange Butterfly Valves

When selecting a double eccentric flange butterfly valve, the choice of manufacturer is as critical as the valve's specifications itself. The market offers a wide array of options, but not all suppliers provide the same level of quality, engineering expertise, and post-sales support. Differentiating between manufacturers requires a close examination of several key factors: material traceability, manufacturing precision, adherence to international standards, depth of engineering support, and track record of successful installations. While some manufacturers may offer lower upfront costs, this often comes at the expense of material quality, looser tolerances, and inferior sealing mechanisms, leading to premature failure, increased maintenance costs, and potential operational disruptions. Reputable manufacturers, on the other hand, invest heavily in R&D, advanced manufacturing equipment (like multi-axis CNC machines for precise eccentricity machining), and rigorous quality assurance protocols, ensuring that their double eccentric flange butterfly valve products deliver consistent, long-term performance. For instance, a leading manufacturer will typically provide full material traceability certificates (MTCs) for all critical components, demonstrating compliance with ASTM, DIN, or EN standards. They will also possess certifications like ISO 9001 for quality management, API 609 for butterfly valve design and testing, and potentially specific certifications for hazardous environments (e.g., ATEX for explosive atmospheres) or potable water applications (e.g., WRAS, NSF). Our organization distinguishes itself by prioritizing these critical factors, offering not just standard valve configurations but also comprehensive custom solutions tailored to the unique demands of specific projects. For example, a client requiring a valve for highly abrasive slurry in a mining operation might need a double eccentric flange butterfly valve with a ceramic-coated disc and a specialized abrasion-resistant seat, a solution that goes beyond standard catalogue offerings. Similarly, an application in a nuclear power plant might necessitate valves designed to withstand specific seismic loads or radiation exposure, requiring specialized materials and rigorous non-destructive testing (NDT) such as ultrasonic testing or radiographic inspection. Our engineering team collaborates closely with clients to understand their precise operational parameters, including fluid characteristics (corrosive, abrasive, high viscosity), pressure and temperature extremes, cycling frequency, actuation requirements, and integration with existing control systems. This collaborative approach allows us to recommend optimal material combinations, design modifications, and testing protocols to ensure the double eccentric flange butterfly valve performs flawlessly in its intended environment. This bespoke service extends to offering various coating options (e.g., epoxy, Rilsan, PTFE lining), specialized actuation packages (e.g., fail-safe spring-return actuators, intrinsically safe electric actuators), and custom end connections beyond standard flanges. We have a robust history of successful case studies where our customized double eccentric flange butterfly valve solutions have significantly improved system reliability and reduced operational costs for clients. For instance, in a challenging chemical processing plant, we developed a valve with a specific Hastelloy C-276 disc and shaft to resist extreme acid concentrations, leading to a 300% increase in valve lifespan compared to previously used models. In a large-scale municipal water project, our customized valves with specialized gearing systems and robust corrosion protection significantly reduced maintenance downtime for critical isolation points. Our ability to provide detailed engineering drawings, comprehensive performance data, and expert technical support throughout the project lifecycle—from conceptual design to installation and commissioning—sets us apart. We don't just supply valves; we provide integrated solutions that ensure optimal fluid control and long-term value, solidifying our position as a trusted partner in industrial infrastructure development. This commitment to customized excellence ensures that our double eccentric flange butterfly valve solutions are not merely off-the-shelf components but precisely engineered tools designed for peak performance in the most challenging industrial landscapes.

| Feature | Standard Double Eccentric Valve (Generic) | Our High-Performance Double Eccentric Valve |

|---|---|---|

| Sealing Mechanism | Resilient seat, often less robust material | Enhanced resilient or metal-to-metal seat, optimized profile for superior bubble-tight seal. |

| Seat Life & Wear | Moderate wear, potential for premature failure | Minimized wear due to precise camming action, significantly extended service life (20+ years). |

| Operating Torque | Moderate to high, depending on seal | Significantly lower, enabling smaller actuators and energy savings. |

| Material Selection | Limited standard options, basic grades | Broad range of premium materials (duplex, Hastelloy, specialized alloys), full traceability. |

| Manufacturing Tolerances | Standard industrial tolerances | Precision CNC machining, tighter tolerances for optimal performance and fit. |

| Certification & Standards | Basic compliance, may lack full traceability | ISO 9001, API 609, ANSI/ASME, EN, with comprehensive documentation and testing. |

| Customization | Minimal to none | Extensive customization options: materials, coatings, actuation, end connections, specialized testing. |

| After-Sales Support | Limited or reactive | Proactive technical assistance, spare parts, training, long-term partnership. |

Ensuring Reliability: Trustworthiness, Support, and Warranty for Double Eccentric Flange Butterfly Valves

Building and maintaining trust with B2B clients in the industrial valve sector is fundamental, especially when dealing with critical infrastructure components like the double eccentric flange butterfly valve. Our commitment to trustworthiness is reflected not only in the superior quality of our products but also in the comprehensive support and transparent policies we offer throughout the entire customer journey. This dedication ensures that our clients receive not just a product, but a complete solution backed by expertise, reliability, and long-term commitment. A core component of our trustworthiness lies in our unwavering adherence to international quality and safety standards. Every double eccentric flange butterfly valve undergoes rigorous testing in accordance with API 598 for valve inspection and testing, guaranteeing bubble-tight shutoff (Leakage Class VI) and pressure integrity. Our manufacturing facilities are certified to ISO 9001, affirming our robust quality management systems from design to delivery. We also ensure compliance with specific industry standards, such as AWWA C504 for rubber-seated butterfly valves or relevant pressure equipment directives (PED) for European markets, where applicable. We openly provide certified test reports, material traceability records, and certificates of conformity for all delivered valves, offering complete transparency and peace of mind. To further instill confidence, we offer an industry-leading warranty of 24 months from the date of installation or 36 months from the date of shipment, whichever comes first, against defects in materials and workmanship. This warranty underscores our confidence in the durability and reliability of our double eccentric flange butterfly valves, providing our clients with significant risk mitigation. Beyond the warranty, our comprehensive customer support system is designed to provide immediate and effective assistance. Our technical support team, composed of experienced valve engineers, is available for pre-sale consultations, guiding clients through material selection and sizing, and post-sale troubleshooting or operational advice. We offer detailed installation guides, maintenance manuals, and training sessions to ensure that client personnel are fully equipped to handle our valves. Spare parts are readily available, ensuring minimal downtime for any required servicing. Our delivery cycles are managed efficiently, with typical lead times ranging from 4 to 8 weeks for standard configurations, and clear communication provided for custom orders which may require longer production schedules due to specialized material procurement or complex manufacturing processes. We leverage a robust logistics network to ensure timely and secure delivery globally, minimizing project delays for our clients. Transparency in pricing, delivery schedules, and after-sales service is a cornerstone of our business philosophy, ensuring clients are fully informed at every stage. We also actively solicit customer feedback to continuously improve our products and services, fostering a partnership approach rather than a transactional one.

Frequently Asked Questions (FAQ) about Double Eccentric Flange Butterfly Valves

Q1: What is the primary advantage of a double eccentric flange butterfly valve over a concentric butterfly valve?

A1: The primary advantage lies in the double offset design, which significantly reduces friction between the disc and the seat during valve operation. In a concentric valve, the disc rubs against the seat throughout the opening and closing cycle, leading to rapid wear. The double eccentric design causes the disc to 'cam' away from the seat almost immediately upon opening, preventing rubbing and thereby extending the seat life, reducing operational torque, and improving sealing performance, especially in high-pressure or high-temperature applications. This design also allows for a true bubble-tight shutoff.

Q2: What industries commonly utilize double eccentric flange butterfly valves?

A2: These valves are widely used across various heavy industries due to their robust design and superior performance. Key sectors include petrochemicals (oil & gas, chemical processing), power generation (thermal, nuclear, hydropower), municipal water and wastewater treatment, HVAC systems, pulp and paper, mining, and metallurgy. They are preferred in applications requiring reliable isolation, high flow capacity, and resistance to harsh media or demanding operating conditions.

Q3: How do you ensure the quality and longevity of your double eccentric flange butterfly valves?

A3: Our quality assurance process is comprehensive, starting from stringent material selection (with full traceability) and continuing through precision manufacturing using advanced CNC machinery. Every valve undergoes rigorous in-house and third-party testing, including hydrostatic shell and seat tests (to API 598 standards), and often fugitive emissions testing (to ISO 15848-1). We adhere to international standards like ISO 9001, API 609, and ANSI/ASME B16.34. Furthermore, our experienced engineering team provides customized solutions and technical support to ensure optimal valve performance for specific client needs, backed by a robust warranty and reliable spare parts availability.

Q4: Are your double eccentric flange butterfly valves suitable for abrasive or corrosive media?

A4: Yes, they are. Our valves can be custom-engineered with specialized materials and coatings to withstand highly abrasive or corrosive media. Options include high-grade stainless steels (e.g., Duplex, Super Duplex), Hastelloy, various lining materials (e.g., PTFE, PFA), and specialized disc coatings (e.g., ceramic, hardened alloys). Our engineering team will work with you to select the appropriate materials and configurations based on the specific media characteristics and operating conditions to ensure maximum lifespan and performance.

Q5: What is the typical lead time for an order of double eccentric flange butterfly valves?

A5: For standard configurations, our typical lead time ranges from 4 to 8 weeks, depending on the order quantity and current production schedule. For highly customized valves or very large projects involving specialized materials and complex manufacturing processes, lead times may be longer. We maintain transparent communication regarding production and delivery schedules and strive to meet our clients' project timelines efficiently. Our global logistics network ensures timely and secure delivery to your specified location.

References and Further Reading

- Valve World Magazine: "High-Performance Butterfly Valves: Design and Application Considerations in Demanding Services." Link to Article

- Journal of Pressure Vessel Technology (ASME): "Advances in Sealing Technologies for High-Performance Industrial Valves." Link to Abstract (requires subscription for full access)

- API Standard 609: "Butterfly Valves: Double-Flanged, Lug-Type, and Wafer-Type" (Referenced standard for design and testing). Link to API Standard Overview

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025