Oct . 05, 2024 15:50 Back to list

Grooved End Design for Efficient Butterfly Valve Solutions

Understanding Grooved End Butterfly Valves A Comprehensive Overview

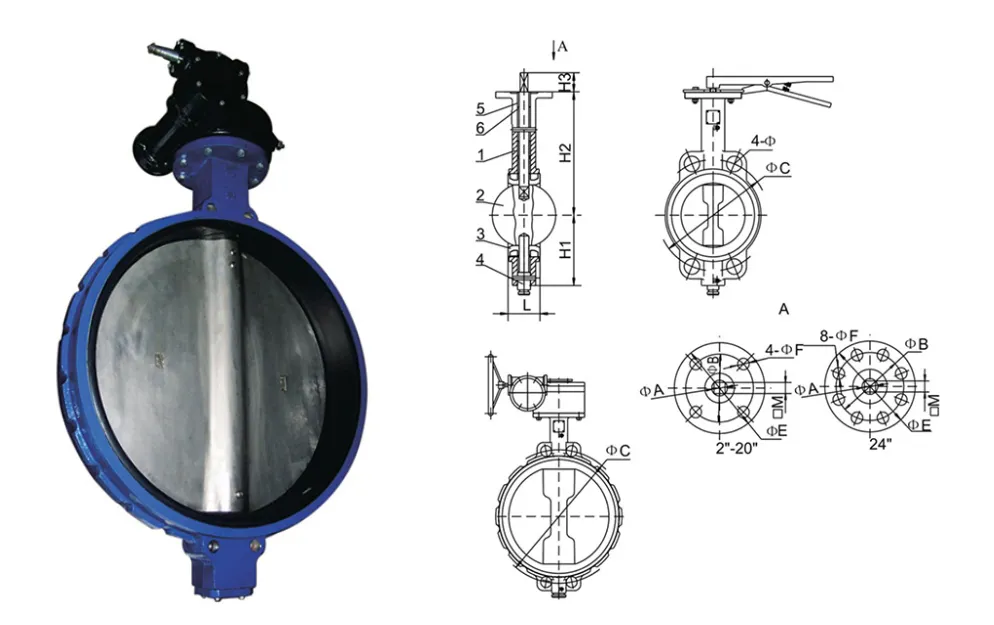

Grooved end butterfly valves are an essential component in modern piping systems, featuring a unique design that enhances flow control and efficiency. These valves are characterized by their simplicity and robust construction, making them suitable for various applications in industries such as water treatment, chemical processing, and HVAC systems.

The primary function of a butterfly valve is to regulate fluid flow. The valve consists of a disk, or “butterfly,” which rotates around a central axis. When the valve is fully open, the disk is parallel to the flow, allowing maximum fluid passage. Conversely, rotating the disk 90 degrees closes the valve, effectively blocking the fluid flow. This design provides quick and efficient operation, often requiring only a quarter-turn to fully open or close.

One distinguishing feature of grooved end butterfly valves is their unique connection method. Unlike traditional flanged valves, which require bolting and gaskets for installation, grooved end valves utilize grooves around the valve ends that allow for a secure fit with grooved pipes. This connection method not only simplifies installation but also ensures a leak-proof seal, significantly reducing the potential for leaks and enhancing overall system reliability.

grooved end butterfly valve

Moreover, grooved end butterfly valves are known for their versatility

. They can handle a wide range of fluids, including water, air, and various chemicals, making them suitable for different applications. Their compact design and lightweight nature also contribute to reduced space requirements in piping layouts, allowing for more efficient system designs.In addition to their functional benefits, these valves often come with features that enhance their performance. For instance, many grooved end butterfly valves are equipped with resilient seated designs, which provide superior sealing capabilities, even under varying pressure conditions. This feature is particularly important in applications where maintaining a tight seal is crucial for operational efficiency and safety.

When considering the material composition, grooved end butterfly valves are typically made from durable materials such as stainless steel, ductile iron, or PVC, catering to the needs of specific environments. The choice of material ensures that the valves can withstand corrosion, temperature extremes, and high pressure, thus extending their service life.

In summary, grooved end butterfly valves play a vital role in fluid control across multiple industries. Their efficient operation, ease of installation, and adaptability make them an excellent choice for various applications. As industries continue to evolve and demand more reliable solutions for fluid management, grooved end butterfly valves are likely to remain a critical component in effective piping systems, contributing to enhanced efficiency and safety.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025