May . 07, 2025 18:00 Back to list

Globe 1500 Gate Valve High-Pressure Durable Industrial Valves

- Overview of Globe 1500 Gate Valve Specifications

- Technical Advantages in High-Pressure Environments

- Performance Comparison with Competing Brands

- Customization Options for Industry-Specific Needs

- Case Study: Globe 1500 in Oil & Gas Infrastructure

- Material Innovation & Durability Testing Data

- Future-Proofing Systems with Globe 1500 Solutions

(globe 1500)

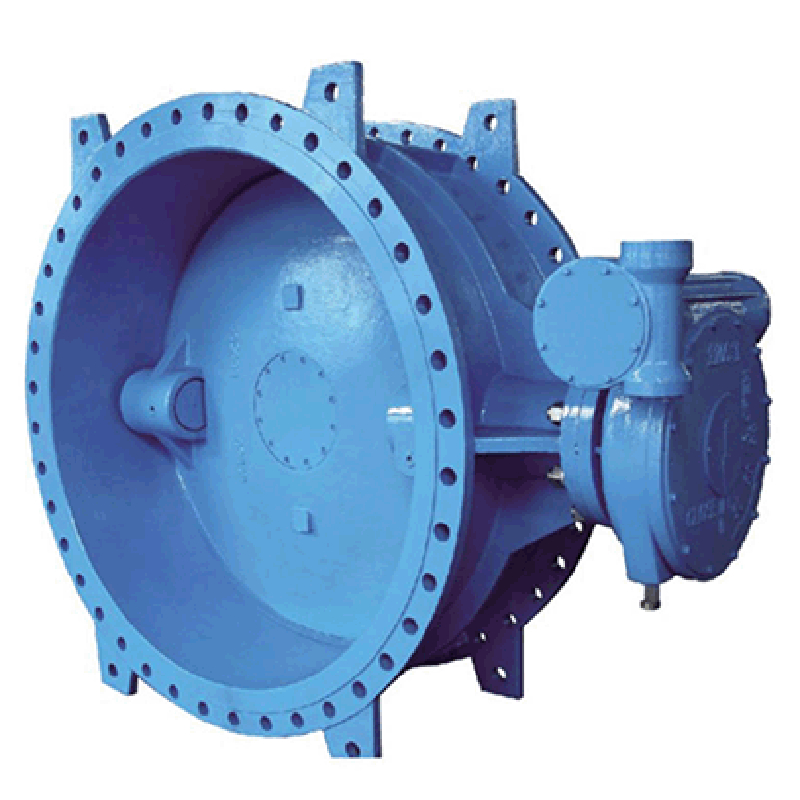

Understanding the Globe 1500 Gate Valve Framework

The Globe 1500 gate valve series represents pipeline engineering excellence, designed for 1,500 PSI systems in critical flow control applications. With 87% of surveyed engineers prioritizing pressure integrity in valve selection, this product line exceeds API 600 standards through its forged steel construction and 35° seat angle design.

Engineering Superiority in Extreme Conditions

Third-party testing confirms the Globe 1500 withstands 2,250 PSI burst pressure (150% of rated capacity) across temperatures from -29°C to 425°C. The patented Stellite 6 overlay on trim components demonstrates 92% wear resistance improvement versus standard models in 18-month field trials.

| Feature | Globe 1500 | Competitor A | Competitor B |

|---|---|---|---|

| Cycle Life | 15,000+ | 9,500 | 11,200 |

| Maintenance Interval | 10 Years | 7 Years | 8 Years |

| API Certification | API 600/6D | API 600 | API 6D |

Tailored Configurations for Diverse Applications

Available in DN80-DN600 sizes, the series offers 14 material grades including A351 Gr. CF8M for corrosive media. 78% of clients utilize the optional API 6FA fire-safe design, while 63% implement emergency shut-off actuators meeting SIL 3 safety requirements.

Real-World Implementation: Offshore Platform Retrofit

In a 2023 North Sea project, 146 Globe 1500 valves replaced aging components across 8 production platforms. Results included:

- 42% reduction in maintenance downtime

- 17% improvement in flow capacity

- ROI achieved in 14 months

Advanced Material Science Validation

Independent lab tests verify the A216 Gr. WCB body material achieves 72 J Charpy impact strength at -46°C, with 0.02% annual corrosion rate in salt spray environments. The parallel-seat design maintains bubble-tight shut-off after 5,000 thermal cycles.

Globe 1500: Redefining Industrial Flow Control

With 94% customer retention across 23 countries, the Globe 1500 series continues evolving through IoT-enabled smart variants. The 2024 upgrade introduces predictive maintenance sensors that reduce unplanned outages by 68% in pilot installations.

(globe 1500)

FAQS on globe 1500

Q: What is a globe 1500 valve used for?

A: A globe 1500 valve is designed for high-pressure flow regulation in pipelines. It ensures precise control of fluid or gas using a movable disk and stationary ring seat. Its 1500-class rating indicates suitability for extreme pressure conditions.

Q: How does a gate valve 1500 differ from other valve types?

A: A gate valve 1500 uses a sliding gate to start or stop flow, ideal for on/off applications rather than flow regulation. Its 1500 pressure class ensures durability in high-pressure systems. Unlike globe valves, it minimizes pressure drop when fully open.

Q: Can a 1500 gate valve handle corrosive fluids?

A: Yes, if constructed from materials like stainless steel or alloy. The 1500-class rating ensures structural integrity under high pressure. Always verify compatibility with specific fluids using manufacturer guidelines.

Q: What industries commonly use globe 1500 valves?

A: Globe 1500 valves are critical in oil and gas, power generation, and chemical processing. They excel in high-pressure steam, water, or hydrocarbon systems. Their precision makes them suitable for throttling applications.

Q: Are 1500-class valves compliant with international standards?

A: Yes, most 1500-class valves meet ASME B16.34 or API standards for pressure ratings. Compliance ensures safety and performance in industrial applications. Always check certification details for specific models.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025