Nov . 24, 2024 16:52 Back to list

Understanding the Function and Importance of Flap Check Valves in Fluid Systems

Understanding Flap Check Valves Importance and Applications

Flap check valves, also known simply as check valves, are essential components in fluid dynamics systems, particularly in piping and drainage. These valves are designed to prevent backflow, ensuring that fluids such as water, oil, or gas flow in one direction only. This capability is critical in various applications, from household plumbing to industrial systems.

What is a Flap Check Valve?

A flap check valve consists of a disc or flap that pivots on a hinge. When fluid flows in the intended direction, the flap opens, allowing the fluid to pass through. However, if the fluid attempts to flow backward, the flap closes due to gravity or the back pressure from the fluid, preventing reverse flow. This simple yet effective design is what makes flap check valves a reliable solution for many fluid management challenges.

The Mechanism of Action

The operational mechanics of flap check valves are straightforward. The valve is installed in a system, typically along horizontal pipes. When there is an increase in pressure from the inlet side, the flap swings open, enabling flow. When the pressure drops or when back pressure is detected, gravity causes the flap to return to its closed position, thus sealing the valve. This mechanism not only helps in maintaining the flow direction but also protects pumps and other equipment from the damaging effects of backflow, including water hammer, erosion, and sediment buildup.

Types of Flap Check Valves

Flap check valves come in various types, each suited to specific applications. Here are some common designs

1. Vertical Flap Check Valve This type is installed vertically and is typically used in high-pressure applications and where the medium being transported has a significant risk of backflow.

2. Horizontal Flap Check Valve Installed horizontally, this valve is ideal for less critical applications and is often seen in residential plumbing.

3. Spring-Assisted Check Valve Employing a spring mechanism, this valve ensures that the flap closes quickly, offering a faster response to backflow compared to gravity-only models.

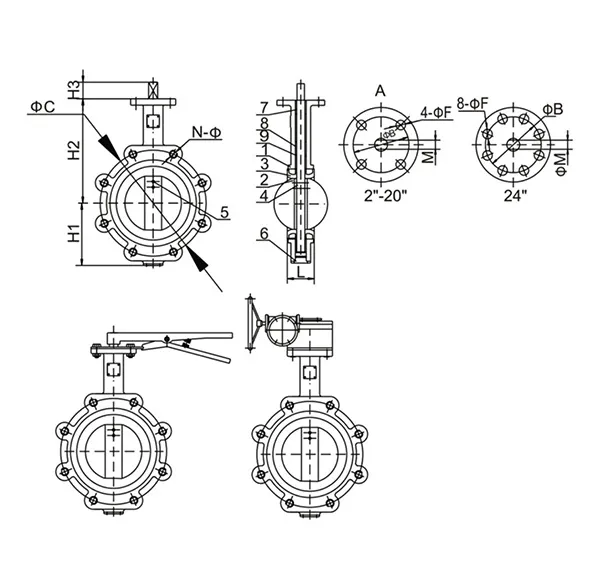

4. Wafer Check Valve This lightweight and compact design is used in applications where space is limited. It fits between two flanges in a pipe system.

Each type has its unique advantages, and the choice often depends on factors such as the nature of the fluid, the size of the pipe, and specific system conditions.

Applications of Flap Check Valves

flap check valve

Flap check valves are widely used across various industries and applications

- Water Supply and Wastewater Management These valves are crucial in sewage systems and water treatment facilities. They prevent the backflow of contaminated water into clean supply lines.

- Oil and Gas Industry In pipelines transporting crude oil or natural gas, flap check valves are integral in protecting against backflow that could lead to environmental hazards.

- HVAC Systems They play a vital role in heating, ventilation, and air conditioning systems, ensuring that air flows in the intended direction without any reversal that can disrupt efficiency.

- Fire Protection Systems In fire suppression systems, flap check valves ensure that the water flows to the necessary locations without risking reverse flow that could compromise the system.

Advantages of Flap Check Valves

The benefits of using flap check valves are numerous

1. Prevent Backflow As the primary function, flap check valves effectively safeguard systems from reverse flow, protecting equipment and maintaining system integrity.

2. Low Maintenance The simple design typically means lower maintenance costs, as fewer moving parts are involved.

3. Versatility They can handle various fluids, including liquids and gases, making them suitable for diverse applications.

4. Durability Made from robust materials, flap check valves are able to withstand harsh conditions, including high pressures and corrosive substances.

Conclusion

In summary, flap check valves play a pivotal role in modern fluid management systems. Their uncomplicated yet effective design facilitates one-directional flow, protecting systems from backflow and its associated risks. With a variety of options available, these valves can cater to many industries, ensuring efficiency and safety in fluid transport operations. Whether in a small residential plumbing system or a large-scale industrial application, flap check valves are indispensable components that help maintain the integrity of fluid handling systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025