Dec . 17, 2024 14:33 Back to list

flange dismantling joint

Understanding Flange Dismantling Joints A Key Component in Modern Engineering

Flange dismantling joints are critical components used across various engineering applications, particularly in piping systems. These joints enable easy assembly, disassembly, and maintenance of pipelines without the need for extensive mechanical tools or disruption of the system. In this article, we will explore the functionality, benefits, and applications of flange dismantling joints, highlighting their significance in modern engineering practices.

What Are Flange Dismantling Joints?

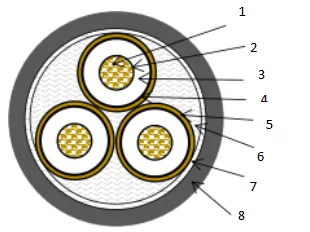

Flange dismantling joints are specialized fittings designed to connect two sections of a pipeline with the ability to be easily dismantled. They typically consist of a flange, which serves as a connecting plate, and a series of bolts that secure the joint in place. These joints often incorporate adjustable telescopic features that allow for length adjustments during installation and maintenance, thereby accommodating thermal expansion and contraction of piping systems.

Key Features and Benefits

1. Ease of Maintenance One of the primary advantages of flange dismantling joints is the ease of access they provide to the pipeline. In scenarios where maintenance or repairs are necessary, these joints allow engineers and maintenance personnel to quickly disconnect and reassemble sections of the pipeline. This reduces downtime and minimizes operational disruptions.

2. Adjustability Most flange dismantling joints are designed to accommodate adjustments in length, which is essential in dynamic environments where thermal expansion can lead to misalignment. This adjustability aids in achieving proper alignment during installation while also providing flexibility for future modifications.

3. No Special Tools Required Unlike conventional bolted flanges that require a range of tools for connection and disconnection, flange dismantling joints can often be operated with minimal tooling. This not only simplifies the maintenance process but also makes it more efficient, as less time is spent gathering tools.

4. Versatility Flange dismantling joints can be employed in various settings, including water treatment plants, chemical processing facilities, and heating systems. They are suitable for use with materials such as metal, plastic, or rubber, making them adaptable to different pipeline compositions and flow media.

flange dismantling joint

5. Reduced Risk of Leakage The design of flange dismantling joints helps to minimize the risk of leaks, which can be a significant concern in pipeline systems. The secure fit provides an effective seal, and maintenance can be performed without the need to completely dismantle adjacent sections, thereby reducing the likelihood of exposing the system to potential leakage points.

Applications of Flange Dismantling Joints

Flange dismantling joints find widespread use in various industries, primarily due to their robustness and adaptability. Some common applications include

- Water Distribution Systems In municipal water supply systems, these joints facilitate maintenance and upgrades without the need for extensive line work. - Heating and Cooling Systems HVAC systems utilize dismantling joints for connecting various components, allowing for efficient access during routine servicing.

- Industrial Process Pipelines In factories where large volumes of materials are processed, dismantling joints enable quick adjustments and maintenance of production lines.

- Wastewater Treatment Facilities These joints are essential in maintaining the integrity of systems that manage the treatment and transport of water, ensuring minimal disruption during repairs or upgrades.

Conclusion

Flange dismantling joints play a vital role in the efficiency and functionality of modern piping systems. Their ability to facilitate easy maintenance, adjustability, and versatility makes them an indispensable element in various engineering applications. As industries continue to prioritize operational efficiency and reliability, the demand for such innovative solutions will undoubtedly grow, highlighting the importance of flange dismantling joints in the future of engineering.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025