Dec . 09, 2024 17:31 Back to list

flanged gate valve

Understanding Flanged Gate Valves Design, Functionality, and Applications

Flanged gate valves are critical components in various industrial applications, particularly in water supply, wastewater management, and chemical processing. These valves are designed to control the flow of fluids through pipelines, offering a reliable means to start or stop flow with minimal pressure drop.

Design and Structure

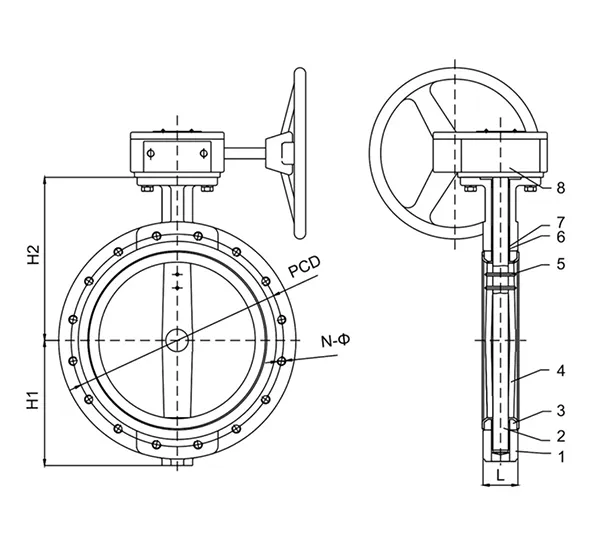

The flanged gate valve features a robust design that includes two flanges attached to the body of the valve. These flanges allow for easy installation and removal, connecting the valve directly to pipeline systems with bolts, ensuring a secure and leak-proof fit. The body of the valve can be made from various materials such as cast iron, stainless steel, or brass, depending on the specific requirements of the application, such as pressure, temperature, and fluid type.

Inside the valve, the gate itself is a solid slab that moves up and down to either allow or block the flow of fluid

. When the valve is fully open, the gate is retracted completely into the body, creating a straight path for fluid to flow without obstruction. This design is particularly advantageous as it minimizes turbulence and pressure loss, making flanged gate valves ideal for systems where flow efficiency is crucial.Functionality and Operation

Flanged gate valves are operated using a handwheel or actuator. When the operator turns the handwheel, the valve stem moves the gate up or down. The movement can be manual or automated, depending on the setup of the specific system. The simplest method of operation involves turning the handwheel counterclockwise to open the valve and clockwise to close it.

flanged gate valve

One of the key benefits of flanged gate valves is that they provide a tight seal when closed, effectively preventing leaks. This is achieved through the use of packing materials around the stem, which can be adjusted to maintain a secure seal over time. Additionally, because the gate is fully retracted when in the open position, there is minimal wear on the valve components, prolonging its lifespan.

Applications

Flanged gate valves are widely used in various industries due to their effectiveness in handling different media, including water, oil, and gas. In municipal water supply systems, these valves are employed to control water flow and manage distribution networks. Their ability to withstand high pressures and temperatures makes them suitable for both industrial and commercial applications.

In wastewater treatment facilities, flanged gate valves play a crucial role in managing the flow of sewage and treated water. Their durability ensures that they can handle the abrasive and corrosive properties of wastewater without significant degradation over time. Similarly, in chemical processing plants, these valves are vital for managing the flow of various chemicals, ensuring safe and efficient operation.

Conclusion

Flanged gate valves are essential for the effective management of fluid systems across a variety of industries. Their design allows for minimal pressure drop and leakage while providing a robust means to control flow. As industries continue to prioritize efficiency and reliability in their operations, flanged gate valves will remain a key component in achieving these goals. Whether in municipal water supply networks or complex chemical processing plants, their versatility and performance make them indispensable in modern fluid control systems. Understanding their design, operation, and applications is crucial for engineers and operators to ensure optimal performance and longevity in various operational contexts.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025