Nov . 04, 2024 18:08 Back to list

Electric Actuated Butterfly Valve for Efficient Flow Control Solutions in Industrial Applications

The Importance of Electric Actuated Butterfly Valves in Modern Industry

In an era of growing industrial automation and the need for efficient control systems, electric actuated butterfly valves have emerged as a pivotal component in various applications. These valves, characterized by their simple and robust design, control fluid flow in a wide array of industries, including water treatment, oil and gas, and food and beverage.

What is an Electric Actuated Butterfly Valve?

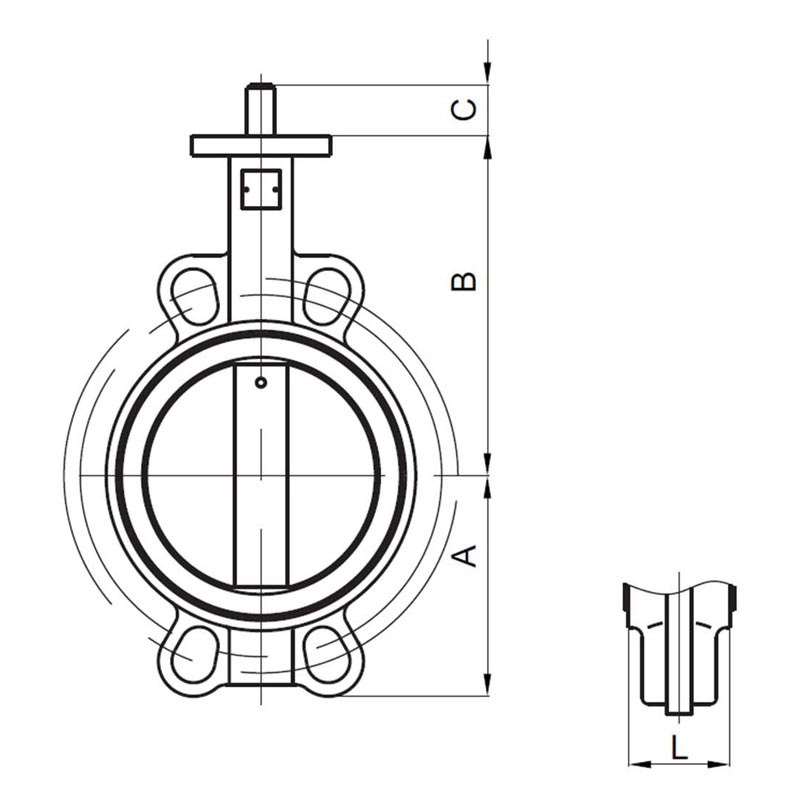

An electric actuated butterfly valve integrates a butterfly valve with an electric actuator. The valve itself consists of a circular disc (the butterfly) that rotates within the pipe to regulate or stop the flow of fluid. When the actuator receives a signal, it rotates the disc from a closed to an open position, allowing fluid to pass through, and vice versa. This mechanism allows for quick and efficient control of flow, making it suitable for applications requiring reliability and precision.

Advantages of Using Electric Actuated Butterfly Valves

1. Efficiency and Speed One of the primary advantages of electric actuated butterfly valves is their ability to operate quickly. The electric actuator can open or close the valve much faster than manual counterparts, facilitating rapid response in dynamic industrial processes.

2. Energy Savings These valves are designed for low power consumption, which is essential in reducing operational costs for industries employing numerous valves across their systems. Efficient energy usage also aligns with global sustainability efforts, making electric actuated butterfly valves an eco-friendly option.

3. Automation Compatibility The integration of electric actuated butterfly valves into automated systems enhances overall process control. With compatibility for various control systems, including PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition), these valves can be programmed for precise flow control, reducing the risk of human error.

electric actuated butterfly valve

4. Compact Design The compact nature of butterfly valves allows for a space-saving installation. They can easily fit into equipment where space is at a premium, making them ideal for modern, upgraded facilities.

5. Minimal Maintenance Compared to other valve types, electric actuated butterfly valves have fewer moving parts, which translates to minimal wear and tear. This reduces maintenance frequency and costs, contributing to a lower total cost of ownership.

Applications in Various Industries

The versatility of electric actuated butterfly valves ensures their application across numerous sectors

- Water Treatment In municipal water treatment plants, these valves are essential for controlling the flow of water, ensuring efficient treatment processes, and responding swiftly to changes in water demand. - Oil and Gas Within the oil and gas industry, these valves handle the flow of crude oil, natural gas, and other hydrocarbons. Their reliability in harsh environments makes them an invaluable part of pipeline systems.

- Food and Beverage Sanitary designs of electric actuated butterfly valves are crucial in the food industry, ensuring safety and compliance with health standards while allowing for precise control over production processes.

Conclusion

As industries increasingly prioritize automation, reliability, and efficiency, electric actuated butterfly valves will continue to play a significant role in fluid control systems. Their speed, energy efficiency, compact design, and minimal maintenance requirements contribute to improved operational performance and reduced costs. With the ongoing advancement in actuator technology and the rising demand for automated processes, the future for electric actuated butterfly valves seems promising. Their ability to integrate seamlessly into modern control systems will ensure they remain a vital component across numerous industrial applications for years to come.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025