Nov . 04, 2024 23:30 Back to list

ductile iron globe valve

Ductile Iron Globe Valve A Reliable Choice for Fluid Control

Ductile iron globe valves are essential components in various industrial applications, particularly in fluid control systems. Known for their strength, durability, and excellent mechanical properties, these valves are increasingly favored over traditional cast iron valves. The unique attributes of ductile iron make it an ideal material for manufacturing globe valves that ensure efficient and reliable regulation of fluid flow.

One of the primary advantages of ductile iron is its ability to withstand high stress and pressure, making it suitable for applications in water treatment plants, power stations, and chemical processing facilities. Unlike standard cast iron, which can be brittle and prone to cracking, ductile iron exhibits remarkable toughness and resilience. This property enables globe valves made from ductile iron to perform effectively under demanding conditions, providing extended service life and reduced maintenance costs.

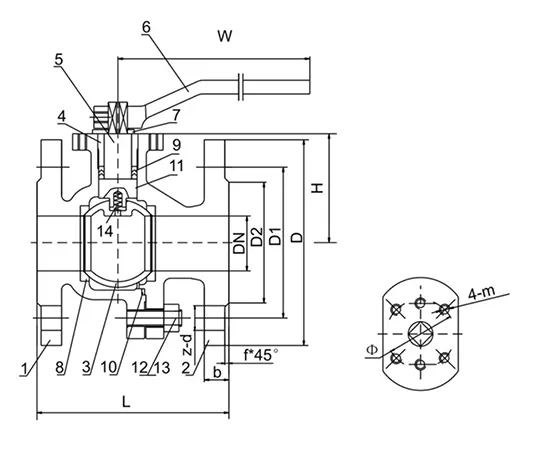

Globe valves themselves are designed to regulate flow in a pipeline through the use of a movable disk that controls the passage of the fluid. The distinctive shape of a globe valve allows it to provide a tight seal, ensuring minimal leakage during operation. This characteristic is particularly vital in systems where fluid loss can result in safety hazards or significant economic impacts. Moreover, ductile iron globe valves feature a straightforward design that allows for easy disassembly and maintenance, further enhancing their appeal in various applications.

ductile iron globe valve

In terms of versatility, ductile iron globe valves come in a range of sizes and pressure ratings, making them adaptable to various industrial requirements. They can be configured with different types of connections, including flanged and threaded ends, allowing for seamless integration into existing piping systems. The availability of various coatings and linings also enables protection against corrosion and wear, ensuring that the valves remain functional even in harsh environments.

Additionally, the environmental footprint of ductile iron is relatively low when considering its longevity and recyclability. As industries increasingly prioritize sustainability, the adoption of ductile iron globe valves aligns well with eco-friendly practices. Manufacturers can source raw materials responsibly, and at the end of their service life, these valves can be recycled, contributing to a circular economy.

In conclusion, ductile iron globe valves are a robust and efficient choice for controlling fluid flow across a variety of industrial applications. Their durability, ease of maintenance, and adaptability make them a preferred option for engineers and facility managers alike. As industries continue to evolve, ductile iron globe valves are poised to play a significant role in enhancing the reliability and efficiency of fluid control systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025