Dec . 06, 2024 03:38 Back to list

Ductile Iron Check Valves for Reliable Performance in Fluid Control Systems

Ductile Iron Check Valves A Reliable Solution for Fluid Control

Ductile iron check valves are essential components in various fluid handling systems, providing a reliable means of preventing backflow and maintaining pressure in pipelines. Known for their durability, strength, and versatility, these valves have become a preferred choice in industries ranging from water and wastewater management to oil and gas.

What are Ductile Iron Check Valves?

Ductile iron, an alloy of iron that includes a small amount of magnesium, is known for its exceptional mechanical properties. It combines the strength of cast iron with the ductility of steel, making it ideal for manufacturing check valves. A check valve, sometimes referred to as a non-return valve, is designed to allow fluid to flow in one direction while preventing reverse flow. This is particularly vital in systems where backflow could result in contamination, equipment damage, or operational inefficiencies.

Benefits of Ductile Iron Check Valves

1. Strength and Durability Ductile iron check valves are robust and can withstand high pressures and adverse environmental conditions. Their resilience makes them suitable for both above-ground and underground applications, ensuring long-term performance.

2. Corrosion Resistance Many ductile iron check valves are coated with protective layers, such as epoxy or polyurethane, to enhance their resistance to corrosion. This feature is particularly important in applications involving water and wastewater, where exposure to corrosive agents is common.

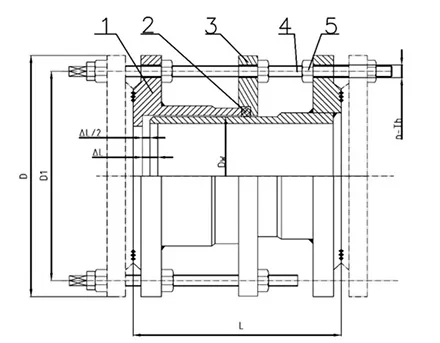

ductile iron check valve

3. Cost-Effectiveness Ductile iron is generally more economical than equivalent materials like stainless steel. This cost-effectiveness, coupled with the valves' durability, makes them a popular choice for many projects, helping to reduce long-term maintenance and replacement costs.

4. Versatility Ductile iron check valves can be used in various applications, including HVAC systems, chemical processing, and municipal water systems. Their adaptability allows engineers to select the appropriate valve for specific operational requirements without compromising efficiency.

5. Ease of Installation The design and construction of ductile iron check valves are typically user-friendly. They can be easily installed in both horizontal and vertical orientations, making them convenient for integration into existing systems.

Applications of Ductile Iron Check Valves

Ductile iron check valves find applications in numerous sectors. In the water and wastewater industry, they prevent backflow in treatment plants and distribution systems, ensuring the integrity of drinking water supplies. In the oil and gas industry, these valves are critical in protecting pumps and refining processes from reverse flow, which can lead to spills and safety hazards. Moreover, they are extensively used in industrial applications, such as cooling systems and chemical processing, where managing fluid flow is crucial to operational efficiency.

Conclusion

In conclusion, ductile iron check valves are indispensable components in modern fluid control systems. Their strength, durability, corrosion resistance, and cost-effectiveness make them a superior choice for various industries. As technology and engineering practices evolve, the demand for reliable and efficient components like ductile iron check valves will only continue to grow. By selecting high-quality check valves, industries can ensure the safety, efficiency, and sustainability of their operations, effectively managing fluid flow while minimizing risks and costs. As we move towards a more industrialized and interconnected world, the role of ductile iron check valves will undoubtedly remain significant in maintaining the integrity of our critical infrastructure.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025