Aug . 30, 2024 00:01 Back to list

Ductile Iron Metal Seat Gate Valve | Durable and Reliable Flow Control

Ductile Iron Metal Seat Gate Valve An Essential Component in Fluid Control

Ductile iron metal seat gate valves are pivotal in the realm of fluid control systems, renowned for their durability, reliability, and versatility. These valves are primarily designed to provide an unobstructed flow path when fully opened, making them favorable for various industrial applications, including water supply, sewage treatment, and oil and gas.

Ductile iron, composed of a high-carbon iron alloy, boasts superior strength and ductility compared to traditional cast iron. This unique composition allows ductile iron gate valves to withstand high levels of stress and corrosion, making them ideal for demanding environments. The incorporation of metal seats in these valves enhances their performance, particularly in high-temperature and high-pressure scenarios, where plastic or elastomeric seats might fail.

One of the most significant advantages of ductile iron metal seat gate valves is their ability to maintain a tight seal. The metal seat design minimizes the risk of leakage, which is crucial in applications involving hazardous materials or where environmental protection is a priority. This attribute not only contributes to operational efficiency but also extends the lifespan of the valve itself, reducing the need for frequent replacements and maintenance.

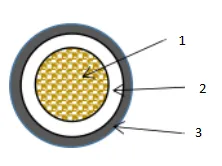

ductile iron metal seat gate valve

In terms of installation and operation, ductile iron gate valves are user-friendly. Their design allows for easy handling and installation, compatible with various piping systems. Additionally, these valves provide quick and reliable shutoff options, with the gate moving vertically between a fully closed and fully open position. This characteristic enables full flow when the valve is open while minimizing pressure drop and turbulence within the system.

Another noteworthy aspect of ductile iron metal seat gate valves is their adaptability. They can be equipped with different types of actuators—manual, electric, or pneumatic—allowing for modifications to meet specific operational requirements. Their versatile design and robust performance make them suitable for industries ranging from water treatment facilities to chemical processing plants.

Moreover, the trend toward sustainability has prompted advancements in ductile iron gate valve technology. Many manufacturers are focusing on eco-friendly production processes and materials, further enhancing the appeal of these valves in a world increasingly concerned with environmental impact.

In summary, ductile iron metal seat gate valves stand out as a reliable choice for fluid control applications. Their strong, corrosion-resistant properties, coupled with effective sealing capabilities, make them a preferred option across various industries. As we move toward more sustainable practices, innovations in valve technology promise to improve both performance and environmental responsibility, ensuring that ductile iron gate valves remain a crucial element in the infrastructure of modern engineering. Investing in such high-quality components not only assures operational efficiency but also contributes to the longevity and reliability of entire fluid systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025