Aug . 29, 2024 22:18 Back to list

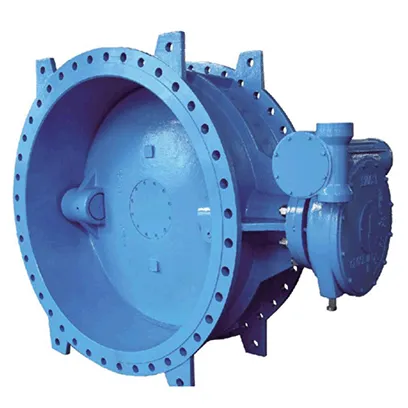

ductile iron check valve

Ductile Iron Check Valves A Comprehensive Overview

Check valves are essential components in many fluid handling systems, preventing backflow and ensuring that liquids and gases flow in the correct direction. One of the most robust and reliable materials used in check valve manufacturing is ductile iron. This article will explore the properties of ductile iron check valves, their applications, advantages, and maintenance considerations.

What is Ductile Iron?

Ductile iron, also known as ductile cast iron or spheroidal graphite iron, is an iron alloy that contains a small amount of alloying elements such as magnesium. This unique composition imparts excellent mechanical properties, including improved ductility, strength, and toughness compared to traditional cast iron. These properties make ductile iron an ideal choice for valves and piping systems subjected to high pressures, severe conditions, and prolonged use.

Applications of Ductile Iron Check Valves

Ductile iron check valves are commonly utilized in various industries, including water and wastewater management, oil and gas, power generation, and chemical processing. In water systems, they prevent the backflow of contaminated water, ensuring clean water supply and protecting municipal systems from potential disruptions. In the oil and gas sector, these valves prevent backflow within pipelines, maintaining flow integrity and safety during transport.

Advantages of Ductile Iron Check Valves

1. Durability and Longevity Ductile iron check valves are known for their long service life. Their ability to withstand harsh conditions, including high temperatures and corrosive environments, ensures that they can maintain operational integrity over extended periods.

ductile iron check valve

2. Cost-Effectiveness While the initial investment for ductile iron valves may be slightly higher than that for other materials, their durability and lower maintenance costs lead to long-term savings. The extended lifespan of these valves means fewer replacements and reduced downtime.

3. Versatility Ductile iron check valves can be designed for various pressure ratings and sizes, making them suitable for a wide range of applications. Their versatility is a significant advantage in industries where system specifications may vary.

4. Ease of Installation These valves are typically designed for straightforward installation. Their standardized sizes and configurations allow for easy integration into existing systems, which can help reduce labor costs during installation.

Maintenance Considerations

To ensure optimal performance and longevity of ductile iron check valves, regular maintenance is essential. Inspecting for signs of wear, corrosion, and malfunctioning seats can help identify any issues early on. Additionally, proper installation and periodic testing of valve functionality should be conducted to maintain system integrity.

It is recommended to establish a routine maintenance schedule that aligns with manufacturer guidelines and operational demands. This proactive approach minimizes the risk of valve failure and the associated costs and disruptions.

Conclusion

Ductile iron check valves play a vital role in many industrial and municipal applications by providing reliable backflow prevention. Their exceptional properties make them a preferred choice in challenging environments where durability and performance are paramount. By understanding their benefits and committing to proper maintenance, organizations can ensure the effective operation of fluid handling systems, safeguarding infrastructure and enhancing efficiency.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025