Nov . 07, 2024 23:03 Back to list

Design and Functionality of Dual Plate Check Valves in Fluid Systems

Understanding Double Plate Check Valves

Double plate check valves, also known as dual plate check valves, are crucial components in various piping systems, particularly in water, oil, and gas applications. These valves play a vital role in preventing backflow, ensuring fluid flows in one direction, and safeguarding the integrity of the system. This article explores what double plate check valves are, their design and functionality, advantages and disadvantages, and applications.

What is a Double Plate Check Valve?

A double plate check valve consists of two plates or discs that swing on a hinge, allowing for rapid closure when flow reverses. Unlike traditional check valves, which may consist of a single disc that pivots, double plate check valves utilize two hinged plates that open and close in response to flow changes. The unique design enables these valves to provide more efficient flow control and minimize turbulence within the system.

Design and Functionality

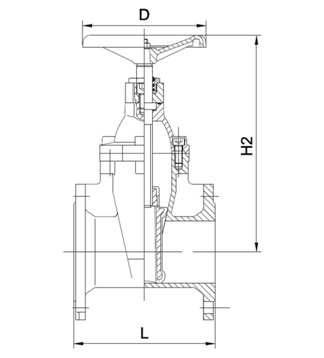

The typical design of a double plate check valve features a compact body, usually made from materials like stainless steel, cast iron, or ductile iron, which can withstand high pressures. The two plates or discs are mounted in a way that they close together against a seat when there is no forward flow, effectively blocking reverse flow.

When the fluid flows in the designated direction, the pressure forces the plates open, allowing the fluid to pass through. When flow ceases or reverses, the weight of the plates, combined with the pressure of the fluid, ensures that the valves close swiftly. This rapid closure prevents water hammer effects, a damaging shock wave caused by sudden changes in flow velocity.

Advantages of Double Plate Check Valves

1. Space Efficiency Due to their compact design, double plate check valves require less space compared to conventional check valves, making them ideal for installations with limited space or for retrofitting existing systems.

2. Low Pressure Drop The streamlined flow path of double plate check valves ensures minimal pressure loss, making them more efficient for fluid transport, particularly in critical applications.

4. Versatile Applications These valves are suitable for a wide range of applications, including wastewater treatment, water supply, fire protection systems, and various industrial processes.

double plate check valve

5. Durability Constructed from robust materials, double plate check valves are designed to withstand harsh conditions and possess a long service life with minimal maintenance.

Disadvantages

Despite their numerous advantages, double plate check valves are not without drawbacks. One of the main concerns is that they are more sensitive to changes in fluid velocity than other types of check valves. This sensitivity can lead to issues if the flow rate is inconsistent or fluctuates significantly. Additionally, while they are effective at preventing backflow, they are not designed to handle certain gases or viscous fluids, which may require different types of valves.

Applications

Double plate check valves are widely used across various sectors, demonstrating their versatility and reliability

- Water Supply Systems They are commonly used in municipal water supply networks to prevent backflow and maintain the integrity of the supply.

- Wastewater Treatment Plants In these facilities, double plate check valves help regulate the flow of treated and untreated water, ensuring that contaminants do not re-enter the system.

- Oil and Gas Industry They are vital in pipeline systems to maintain flow direction and protect against reverse flow in critical applications.

- Fire Protection Systems These valves help ensure that water flows towards the fire suppression systems without the risk of backflow, maintaining pressure within the lines.

- HVAC Systems In heating and cooling systems, double plate check valves can prevent thermal shock and maintain efficient operation.

Conclusion

In summary, double plate check valves are essential for ensuring one-way flow in various applications. Their design offers several benefits, including space efficiency, low pressure drop, and rapid response to flow changes. As industries continue to evolve, the demand for reliable check valves remains crucial to maintaining safe and efficient operations. Understanding the intricacies of double plate check valves enables engineers and system designers to make informed decisions, optimizing their systems for performance and reliability.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025