Nov . 13, 2024 18:38 Back to list

double flanged gate valve

Understanding Double Flanged Gate Valves Design, Function, and Applications

Double flanged gate valves are crucial components in various industrial applications, designed primarily for on-off flow control in pipelines. Their robust structure and reliable performance make them an ideal choice for handling high-pressure and high-temperature liquids and gases, providing essential functionality for various engineering and infrastructure projects. This article delves into their design, operation, and applications.

Design Features

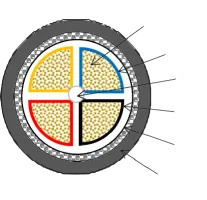

Double flanged gate valves are characterized by their dual flange design, which enables easy installation into a pipeline system. Each valve has flanges at both ends, allowing it to be bolted directly to the pipeline, ensuring a secure and leak-proof connection. The body of a double flanged gate valve is typically constructed from durable materials such as cast iron, ductile iron, or stainless steel, allowing it to withstand harsh operating conditions.

The core component of a gate valve is the gate itself, which is a flat and thick piece of metal that moves vertically in the valve body. This gate slides in and out of the flow path, completely blocking the flow when closed and allowing unrestricted flow when open. Typically, double flanged gate valves feature a rising or non-rising stem design, where the position of the stem indicates whether the valve is open or closed. This design is particularly beneficial in applications where space is at a premium.

Operation Mechanism

The operation of a double flanged gate valve is straightforward. When the valve is actuated via a handwheel or motorized actuator, the stem moves the gate up or down. In the open position, the gate retracts completely into the valve body, allowing for smooth and unobstructed fluid flow. Conversely, when the valve is closed, the gate seats firmly against the valve's body, preventing any flow and maintaining pressure in the system.

double flanged gate valve

One of the significant advantages of double flanged gate valves is their minimal pressure drop across the valve when fully open, which is essential in systems requiring efficiency and reduced energy consumption.

Applications

Double flanged gate valves find applications across various sectors, including water and wastewater management, oil and gas, power generation, and chemical processing. In water treatment plants, for instance, they are used to control the flow of water and sludge during treatment processes. Similarly, in the oil and gas industry, they facilitate the regulation of crude oil and natural gas, playing a vital role in upstream and downstream processes.

These valves are also essential in power plants where they control the flow of cooling water and steam. Additionally, in chemical processing, these valves manage the flow of corrosive and non-corrosive fluids, proving their versatility across different applications.

Conclusion

In conclusion, double flanged gate valves are essential components in modern piping systems, providing reliable, efficient, and effective control of fluid flow. Their robust design and simple operation make them suitable for various applications, from water treatment to industrial processes. As infrastructure and industry continue to evolve, the importance of such reliable components is ever-increasing, ensuring that they remain a staple in engineering and system design for years to come. Understanding their characteristics and capabilities helps engineers and operators make informed decisions about their use in various applications, ultimately leading to safer and more efficient operations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025