Sep . 26, 2024 04:17 Back to list

Double Offset Flanged Butterfly Valve Design and Applications for Fluid Control Systems

Understanding Double Eccentric Flange Butterfly Valves

Butterfly valves are essential components in various industrial applications, primarily for regulating and isolating fluid flow. Among the different types of butterfly valves available, the double eccentric flange butterfly valve stands out due to its innovative design and enhanced performance features. This article explores the characteristics, advantages, and applications of double eccentric flange butterfly valves.

Design and Operation

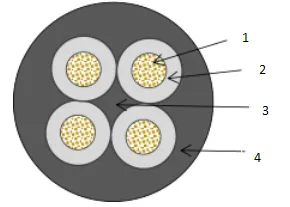

The double eccentric flange butterfly valve, also known as a double offset butterfly valve, features a unique design that sets it apart from traditional butterfly valves. In this design, the rotating disc is positioned at an offset angle from both the valve's centerline and the seat. This double eccentricity minimizes friction between the disc and the seat during operation, which allows for smoother and more efficient movement.

When the valve is opened, the disc moves away from the seating area, reducing wear and tear over time. This design also allows the valve to maintain a tighter seal when closed, preventing leakage in high-pressure applications. Additionally, the flange connection facilitates easy installation and maintenance, making it a preferred choice in various industries.

Advantages of Double Eccentric Flange Butterfly Valves

1. Reduced Torque Requirement The offset design reduces the amount of torque needed to operate the valve. This means that smaller actuators can be used, which helps decrease overall system costs and energy consumption.

2. Enhanced Sealing Performance The double eccentricity allows the disc to move away from the sealing surface, increasing the lifespan of both the valve and the seal. This characteristic is particularly beneficial in applications that require high reliability.

double eccentric flange butterfly valve

3. Versatility These valves can be used in a wide range of applications, including water and wastewater treatment, oil and gas, chemical processing, and HVAC systems. Their ability to handle various fluids, including corrosive substances, makes them suitable for diverse industrial environments.

4. Pressure and Temperature Resistance Double eccentric flange butterfly valves are designed to withstand high pressure and temperature conditions, ensuring safe and reliable operation in demanding environments.

5. Compact Design Compared to other valve types, butterfly valves have a smaller footprint, allowing for more efficient use of space within piping systems.

Applications

Double eccentric flange butterfly valves are widely used in many industries. In water treatment plants, they regulate the flow of treated water. In the oil and gas industry, these valves manage the flow of crude oil and natural gas, where leakage could have significant environmental impacts. Additionally, their ability to handle high temperatures makes them suitable for steam and other heating applications in power plants.

Conclusion

The double eccentric flange butterfly valve represents an advanced solution for fluid control, offering several advantages over traditional valve designs. Its unique construction not only improves operational efficiency but also enhances durability and performance in various applications. As industries continue to seek reliable and efficient solutions, the double eccentric flange butterfly valve will undoubtedly remain an important choice in fluid management systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025