Nov . 27, 2024 07:47 Back to list

Counterweighted Check Valve Design for Enhanced Performance and Reliability

The Functionality and Importance of Check Valves with Counterweights

Check valves are essential components in fluid systems, ensuring that the flow of the fluid is maintained in one direction, thereby preventing backflow. Within this category, check valves with counterweights stand out for their unique design and benefits, particularly in various industrial applications. This article explores the functionality, advantages, and applications of check valves with counterweights.

Understanding Check Valves

Before diving into check valves with counterweights, it’s important to understand the basic function of check valves. A check valve, often referred to as a one-way valve, is designed to prevent the reverse flow of fluids in piping systems. Typically, they operate automatically, meaning they do not require any external force to open or close. The primary mechanism involves a disc or a ball that moves freely within the valve body, allowing fluid to flow in the designated direction while sealing off against reverse flow.

What is a Check Valve with Counterweight?

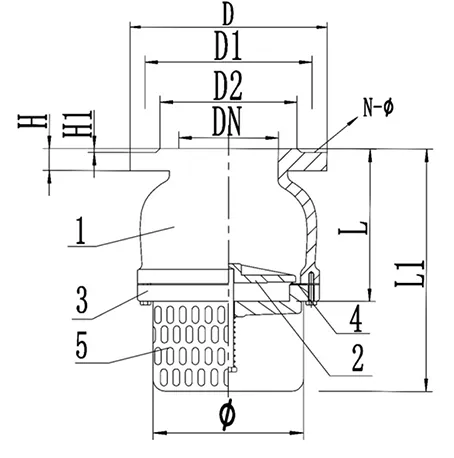

A check valve with a counterweight is a specialized type of check valve that incorporates a counterweight mechanism to enhance its performance. In such configurations, a weight is attached to the valve’s disc or flap. This added counterweight influences the opening and closing behavior of the valve, allowing for improved response to changes in pressure or flow rates.

The counterweight assists in keeping the valve closed when there is little or no flow, effectively sealing against backflow. Conversely, when the fluid flow increases, the force exerted by the fluid can lift the counterweighted disc, enabling fluid to pass through. The counterweight's mass and positioning are crucial as they dictate the valve's performance characteristics, including how quickly it opens or closes and the pressure differential required for operation.

Advantages of Check Valves with Counterweights

1. Enhanced Stability The counterweight provides additional stability to the valve, ensuring it remains closed under low-flow conditions. This is particularly beneficial in systems where backflow could lead to contamination or system inefficiencies.

check valve with counterweight

2. Reduced Chattering One common issue in standard check valves is chattering, where the valve rapidly opens and closes due to fluctuations in pressure. The counterweight helps to dampen these movements, leading to smoother operation and reduced wear on the valve components.

3. Improved Response With an adequately designed counterweight, the check valve can respond more effectively to changes in flow or pressure, thus improving overall system performance. This responsiveness is vital in dynamic systems where flow rates can change abruptly.

4. Versatile Applications Check valves with counterweights are versatile and find applications across various industries. They are commonly used in water treatment plants, chemical processing, irrigation systems, and even in machinery where flow direction must be strictly controlled.

5. Low Maintenance Due to their simple mechanical design and effective sealing capabilities, these valves generally require minimal maintenance over their operational life. This quality makes them a cost-effective solution in the long term.

Applications in Industry

Check valves with counterweights are particularly useful in industries where flow direction needs to be tightly controlled. In water treatment plants, they prevent the backflow of potentially contaminated water, ensuring the safety and quality of the water supply. Similarly, in chemical processing, preventing backflow is crucial to avoid hazardous reactions.

In irrigation systems, where the water needs to flow efficiently and reliably, these valves help maintain system integrity by preventing backflow into the water source. Furthermore, in various machinery applications, they assist in maintaining hydraulic pressure in systems, enhancing overall performance and reliability.

Conclusion

Check valves with counterweights represent a sophisticated solution to the age-old problem of backflow in fluid systems. With their unique design and numerous benefits, these valves play a critical role in ensuring fluid systems operate efficiently and safely across many industrial applications. As industries continue to evolve and demand higher standards of performance, embracing advanced technologies like counterweighted check valves will be essential for achieving optimal fluid management.

Share

-

Advanced Technology in Wire and Cable FactoryNewsAug.19,2025

-

Applications of Ball Check Valve in Water Treatment PlantsNewsAug.19,2025

-

How Osy Gate Valve Ensures Leak - Tight SealingNewsAug.19,2025

-

Selection Criteria for Wafer Type Butterfly ValveNewsAug.19,2025

-

Threaded Ball Valve Pressure RatingsNewsAug.19,2025

-

Y Strainer PN16 Cost - Effectiveness AnalysisNewsAug.19,2025