Dec . 05, 2024 13:15 Back to list

Understanding the Benefits and Applications of Cast Steel Valves in Industrial Settings

The Importance and Benefits of Cast Steel Valves in Modern Industry

Cast steel valves are a pivotal component in a broad spectrum of industrial applications, playing a crucial role in regulating, directing, and controlling the flow of fluids and gases. Due to their robust construction and versatility, they are extensively used across various sectors, including oil and gas, water treatment, power generation, and chemical manufacturing.

The manufacturing process of cast steel valves typically involves pouring molten steel into a mold to create a desired shape. This process allows for intricate designs and geometries that enhance performance and functionality. Cast steel is known for its excellent mechanical properties, including high strength, durability, and resistance to wear and corrosion. These characteristics make it an ideal material for valves that operate under high pressure and temperature conditions.

One of the primary advantages of cast steel valves is their ability to maintain integrity under extreme conditions. In industries such as oil and gas, valves often face high pressures and temperatures. Cast steel valves, with their high tensile strength and fatigue resistance, are capable of withstanding these challenging environments. This reliability is crucial for ensuring the safe and efficient operation of industrial processes.

Moreover, cast steel valves exhibit excellent sealing capabilities

. This feature is essential for preventing leaks of hazardous fluids and gases, which can pose significant safety risks and environmental hazards. Effective sealing not only enhances safety but also contributes to the overall efficiency of system operations by minimizing product loss and reducing the risk of contamination.cast steel valve

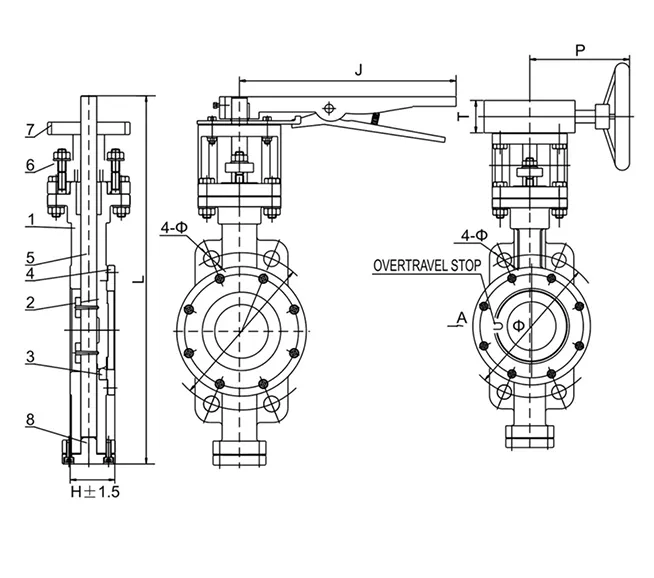

Another important aspect is the versatility of cast steel valves. They are available in a variety of types, including gate valves, globe valves, ball valves, and check valves, each designed for specific applications. This wide range of options allows engineers and designers to select the most suitable valve for their operations, ensuring optimal performance and reliability.

Cast steel valves are also notable for their ease of maintenance. Many designs incorporate features that facilitate quick and easy disassembly, which is essential for regular inspection and repair. This ease of maintenance reduces downtime in industrial operations, ultimately leading to cost savings and more efficient workflows.

In addition to their functional benefits, cast steel valves are often favored for their economic advantages. While the initial investment may be higher compared to other valve materials, their longevity and low maintenance requirements lead to lower lifecycle costs. Investing in high-quality cast steel valves can provide considerable savings over time, especially in applications where equipment failure could lead to costly downtime or repairs.

Furthermore, advancements in manufacturing technology have enhanced the quality and performance of cast steel valves. Modern casting techniques allow for improved precision in valve design and production, resulting in better fitting and reduced risk of failure. Innovations such as automation and quality control processes contribute to producing more reliable and efficient valves that meet the needs of today’s demanding industries.

In conclusion, cast steel valves are an indispensable element in a variety of industrial applications, offering a blend of strength, durability, and versatility. Their ability to perform reliably under extreme conditions, along with excellent sealing capabilities and ease of maintenance, makes them a preferred choice among engineers and industrial operators. As industries continue to evolve and face new challenges, the importance of high-quality cast steel valves will undoubtedly remain significant in ensuring operational efficiency and safety. Investing in these valves can lead to long-term benefits, ultimately supporting the growth and sustainability of industrial operations worldwide.

Share