Oct . 11, 2024 19:20 Back to list

casting ball valve

Understanding Casting Ball Valves Functionality, Benefits, and Applications

In the realm of fluid control devices, the casting ball valve stands out as a crucial component for managing the flow of liquids and gases in various industrial applications. With its robust design and reliable performance, this type of valve has gained popularity across multiple sectors, including oil and gas, water treatment, and chemical processing. In this article, we delve into the fundamental aspects of casting ball valves, exploring their functionality, advantages, and typical applications.

What Are Casting Ball Valves?

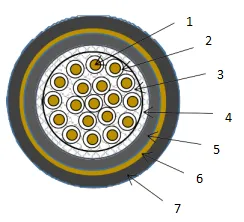

A casting ball valve is a type of quarter-turn valve that uses a hollow, perforated, and pivoting ball to control flow. The valve is named after its construction method, in which the body is cast from materials such as stainless steel, carbon steel, or bronze, rather than being fabricated from sheet metal. This casting process allows for more intricate designs and improved structural integrity, ensuring durability and performance even under high-pressure conditions.

The primary mechanism of a casting ball valve includes three main parts the valve body, the ball, and the actuator. When the ball is rotated to a 90-degree angle, the valve opens, allowing fluid to flow through the passage. Conversely, when the ball is rotated back, the flow is completely shut off. This simple yet effective mechanism makes ball valves ideal for on-off applications.

Key Features and Benefits

1. Durability and Reliability Casting ball valves are built to withstand extreme temperatures and pressures, making them suitable for a wide range of industrial environments. The casting process imparts strength and longevity to the valves, even when used with corrosive materials.

2. Low Resistance to Flow The design of the ball valve features a smooth, spherical surface that minimizes turbulence and pressure drops when fluid passes through. This low flow resistance enhances system efficiency and reduces energy consumption.

3. Quick Operation The quarter-turn operation allows for rapid opening and closing of the valve, which is essential in scenarios that require immediate flow control. Operators can quickly switch the valve position, facilitating enhanced operational flexibility.

4. Tight Sealing A well-designed casting ball valve provides tight sealing, preventing leaks even under high pressure. This capability is critical in applications where fluid integrity must be maintained, such as in the oil and gas industry.

casting ball valve

5. Versatility Casting ball valves are available in various sizes, materials, and designs, making them suitable for a wide array of fluid types, including water, oil, gas, and chemicals. Their adaptability allows them to meet the specific requirements of different industries.

Applications of Casting Ball Valves

The versatility of casting ball valves enables their use in numerous applications across various sectors. Some common applications include

- Oil and Gas Industry In this sector, casting ball valves are integral to controlling the flow of crude oil and natural gas. Their robust construction ensures they can handle the high pressures associated with these substances.

- Water Treatment Plants Ball valves are often used in water treatment facilities to regulate the flow of water and wastewater. Their reliability and ability to handle fluctuating pressures make them ideal for such critical applications.

- Chemical Processing In chemical plants, casting ball valves manage the flow of corrosive chemicals safely and efficiently. Their ability to provide tight sealing helps prevent leaks and chemical spills.

- Power Generation In power plants, valves control steam and water flow in various systems, ensuring optimal operation and safety in energy generation processes.

Conclusion

In summary, casting ball valves play an indispensable role in fluid control across diverse industries. Their robust construction, low flow resistance, and quick operational capabilities make them a favored choice for many applications. By understanding their functionality, benefits, and wide-ranging uses, industries can better leverage casting ball valves to improve efficiency and safety in their operations. As technology evolves, we can expect further innovations in valve design and materials, enhancing the performance and sustainability of these vital components in fluid management systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025