Oct . 16, 2024 01:26 Back to list

casting ball valve

Casting Ball Valve An Essential Component in Fluid Control Systems

In industrial applications, the efficient control of fluid flow is paramount. One of the key components that facilitate this is the ball valve, specifically the casting ball valve. This type of valve is renowned for its durability, reliability, and excellent sealing capabilities, making it an ideal choice for various industries, including oil and gas, chemical processing, and water treatment.

Understanding Casting Ball Valves

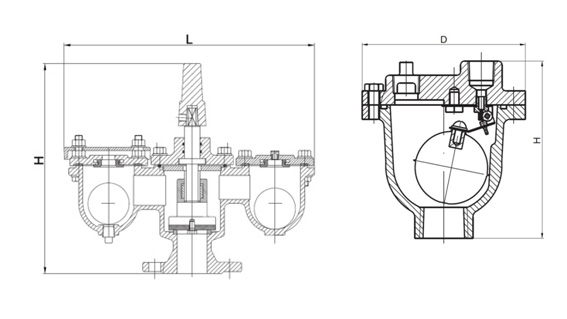

Casting ball valves are precision-engineered devices used to regulate fluid flow. They consist of a spherical disc (the ball) that rotates within a valve body to open or close the flow path. The unique design of the casting ball valve allows for a quarter turn operation, meaning the ball turns 90 degrees to change its state from open to closed. This quick operation ensures minimal pressure drop and allows for efficient flow control.

The term casting refers to the manufacturing process used to create the valve body. In casting methods, molten metal is poured into molds to form the desired shape. This technique allows for intricate designs and robust structures, ensuring that the valve can withstand high pressures and harsh working conditions. Common materials used for casting ball valves include stainless steel, brass, and cast iron, each selected based on the specific application requirements.

Advantages of Casting Ball Valves

One of the primary advantages of casting ball valves is their excellent sealing properties. The design incorporates a resilient seat that ensures a tight seal when the valve is closed, preventing any leakage of fluids. This feature is particularly critical in applications where safety and environmental protection are concerns.

casting ball valve

Another significant benefit is their low maintenance requirements. Due to the durable materials and robust construction used in casting ball valves, they tend to have a long service life. Routine inspections and occasional lubrication are often sufficient to keep them operational, reducing downtime and maintenance costs.

Moreover, casting ball valves offer versatility. They can be used in numerous applications, from controlling water flow in municipal systems to regulating the flow of corrosive chemicals in industrial settings. Their adaptability makes them a popular choice among engineers and designers.

Applications Across Industries

Casting ball valves find applications in various sectors. In the oil and gas industry, they are used to control the flow of hydrocarbons through pipelines, withstanding extreme temperatures and pressures. In chemical manufacturing, these valves help manage the flow of reactive substances safely and efficiently.

In water treatment facilities, casting ball valves play a crucial role in regulating the distribution of water while ensuring compliance with environmental regulations. Their ability to deliver precise control makes them indispensable in processes that require a high level of accuracy.

Conclusion

In summary, casting ball valves are a vital component in fluid control systems across multiple industries. With their robust design, excellent sealing capabilities, and low maintenance needs, they embody reliability and efficiency. As industries continue to innovate and strive for better fluid management solutions, the role of casting ball valves will undoubtedly remain significant, underpinning operations that power our modern world. Whether for high-pressure applications or everyday water management, these valves are essential players in the global industrial landscape.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025