Nov . 21, 2024 01:13 Back to list

ball valve 2 inch

Understanding 2 Inch Ball Valves Functionality, Applications, and Benefits

A 2-inch ball valve is an essential component in various piping systems, serving as a reliable mechanism for controlling the flow of liquids and gases. Ball valves are commonly used due to their durability, straightforward design, and efficiency in sealing, making them an ideal choice for industrial, commercial, and even residential applications.

What is a Ball Valve?

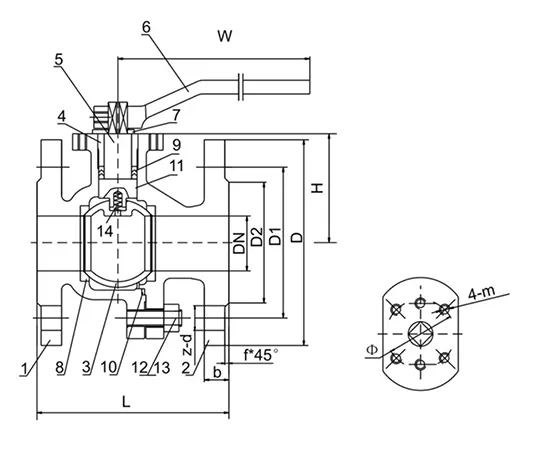

A ball valve is a type of valve that uses a spherical disc, known as a ball, to stop or start the flow of fluid. The ball has a hole through the middle, also known as the bore, which aligns with the flow path when the valve is open, allowing fluid to pass through. When the valve is closed, the ball rotates 90 degrees to block the flow. This design enables quick operation and provides a tight seal, minimizing the leakage of fluids.

Why Choose a 2 Inch Size?

The 2-inch size is a common choice for many applications due to its versatility. It strikes a balance between being large enough to allow substantial flow rates while still being manageable in terms of weight and installation. This size is often utilized in various sectors, such as agriculture, manufacturing, water treatment, and HVAC systems where medium to high flow rates are required.

Key Features and Components

1. Materials 2-inch ball valves are available in various materials such as brass, stainless steel, and PVC. The choice of material often depends on the application's specific requirements, including temperature, pressure, and the type of medium being transported.

2. End Connections The valves can come with different end connections like threaded, flanged, or socket-weld, providing flexibility for installation in existing piping systems.

3. Operation Mechanisms Operated manually or automatically, 2-inch ball valves can be controlled with handles, pneumatic actuators, or electric actuators, allowing for ease of use in various settings.

4. Pressure Rating These valves typically come with pressure ratings suited for various applications, ensuring that they can withstand the operating conditions without failure.

Applications of 2 Inch Ball Valves

The versatility of 2-inch ball valves makes them applicable in numerous fields

ball valve 2 inch

- Industrial Facilities Used in manufacturing processes for controlling the passage of chemicals and other substrates during production.

- Water Treatment Plants They regulate the flow of water and chemical additives during purification processes.

- HVAC Systems Essential for flow control in heating and cooling systems, helping maintain efficient temperature regulation.

- Irrigation Systems Often employed in agricultural settings to manage water flow efficiently for crop irrigation.

Benefits of Using 2 Inch Ball Valves

1. Quick Operation Ball valves can be opened or closed with a simple quarter turn, making them ideal for applications requiring swift action.

2. Low Maintenance Their design allows for minimal wear and tear, resulting in lower maintenance costs over time.

3. Reliability Known for their ability to create a tight seal, ball valves significantly reduce the risk of leaks, enhancing system reliability.

4. Versatile Applications Their different material options and connection types cater to a wide range of industrial needs.

5. Flow Control With the ability to provide excellent throttling capabilities, 2-inch ball valves help maintain desired flow rates in various systems.

Conclusion

In summary, a 2-inch ball valve offers significant advantages for flow control in numerous applications due to its robust design and operational efficiency. Whether in industrial settings, water treatment, HVAC, or agricultural systems, these valves prove indispensable. Choosing the right material and type for specific needs ensures optimal performance and longevity, making them a worthwhile investment for any piping system. Understanding their functionality, applications, and benefits is crucial for anyone involved in system design or maintenance, ensuring smooth operations and effective flow management.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025