Dec . 12, 2024 16:47 Back to list

ball check valve

Understanding Ball Check Valves Function, Types, and Applications

Ball check valves are essential components in various fluid systems, designed to prevent backflow and ensure the proper directional flow of fluids. They play a critical role in maintaining system efficiency and protecting equipment from damage due to reverse flow. This article delves into the function of ball check valves, their types, and their applications across different industries.

Function of Ball Check Valves

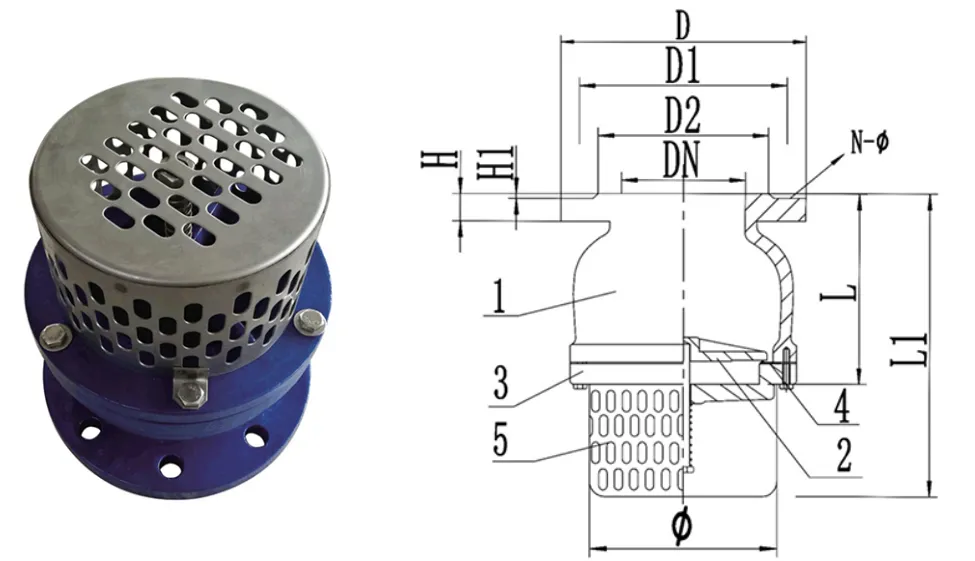

A ball check valve operates using a simple yet effective mechanism. The key component is a spherical ball that resides in the valve body. When fluid flows in the desired direction, the ball is lifted off its seat, allowing fluid to pass through. However, if there is a drop in pressure or a backflow, the ball moves back into place and seals the opening, thereby preventing any reverse flow. This design is favored for its reliability, low maintenance, and ability to handle a wide variety of fluids, including water, oil, and gases.

One of the significant advantages of ball check valves is their ability to respond quickly to changes in flow direction. This rapid operation is crucial in applications where prevention of backflow is necessary, such as in pumps and piping systems.

Types of Ball Check Valves

Ball check valves come in various designs, each suited to specific applications and operating conditions

. The most common types include1. Spring-Loaded Ball Check Valves These valves incorporate a spring mechanism to hold the ball against the seat. This design ensures seals tightly and prevents backflow even during minimal flow conditions. They are ideal for low-pressure applications and situations where backflow prevention is critical.

2. Gravity Ball Check Valves These valves rely on gravity to keep the ball seated when fluid is not flowing. They are typically used in applications with high flow velocities, allowing the ball to lift easily with the flow and drop back into place when flow stops.

3. Piston Check Valves Although not a traditional ball check valve, this type employs a piston mechanism that operates similarly. Instead of a ball, a disc or piston rises to allow flow and drops to seal against backflow. They are beneficial in high-pressure systems where a sturdy design is required.

ball check valve

Applications of Ball Check Valves

Ball check valves have diverse applications across various industries, including

1. Water and Wastewater Management In municipal water systems, ball check valves are commonly used in pump discharge lines to prevent backflow that could lead to contamination. They help in maintaining the integrity of drinking water and managing wastewater efficiently.

2. Industrial Processes In manufacturing and processing facilities, ball check valves are installed in lines carrying chemicals or other fluids. They ensure that valuable materials are not lost due to backflow and protect equipment from damage.

3. Oil and Gas Industry These valves are crucial in oil refineries and pipelines, where they prevent backflow that could lead to catastrophic failures. Their robust design ensures they can withstand the harsh conditions often found in these environments.

4. HVAC Systems In heating, ventilation, and air conditioning systems, ball check valves are used to prevent reverse flow in condensate drainage systems, thereby protecting the equipment and enhancing efficiency.

5. Marine Applications In maritime systems, these valves ensure that water does not flow back into critical engine components, safeguarding the vessels during operations.

Conclusion

Ball check valves are indispensable in numerous industries, providing a reliable solution for preventing backflow and maintaining system integrity. Their straightforward yet effective design and versatility make them a preferred choice in various applications. Understanding the types available and their specific uses can help engineers and operators make informed decisions when selecting and implementing ball check valves in their systems. Whether in municipal water systems, industrial processes, or marine applications, ball check valves continue to play a vital role in ensuring the smooth operation of fluid systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025